Sure! Here’s a concise FAQ for sourcing packing machines from SourcifyChina factory:

1. What types of packing machines does SourcifyChina factory offer?

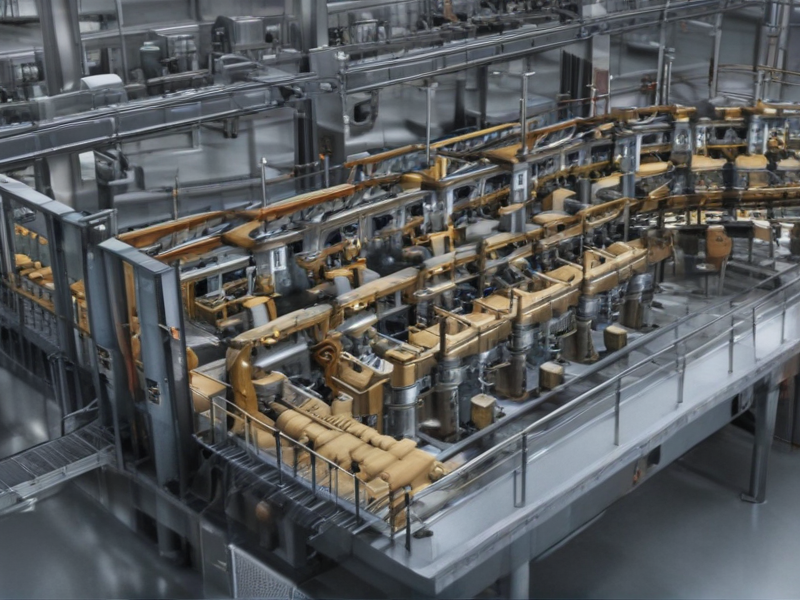

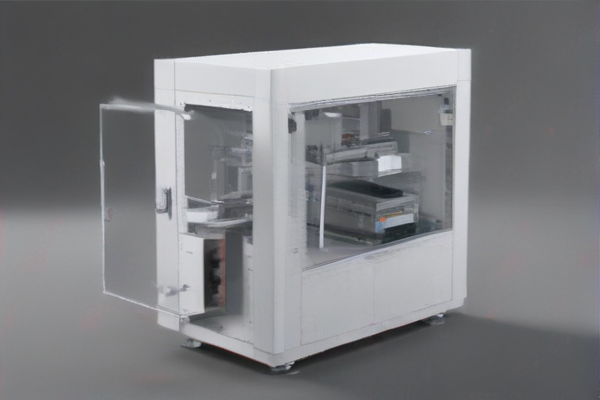

SourcifyChina factory offers a wide range of packing machines, including automatic, semi-automatic, and manual machines for various packaging needs such as filling, sealing, labeling, and wrapping.

2. How can I ensure the quality of the packing machines?

SourcifyChina maintains rigorous quality control procedures. Machines undergo thorough testing and inspection before shipment. Additionally, certifications like CE and ISO are available to guarantee quality.

3. What is the lead time for delivering a packing machine?

Lead times typically range from 2-6 weeks, depending on the machine type and order quantity. Custom orders may have longer lead times.

4. Can I customize the packing machines according to my requirements?

Yes, SourcifyChina offers customization options to meet your specific needs. You can discuss custom requirements with their technical team to ensure the machine fits your purpose.

5. What are the payment terms?

Common payment terms include a 30% deposit upon order confirmation and the remaining 70% balance before shipment. They accept payments via T/T, L/C, and other secure methods.

6. Is there after-sales support available?

Yes, SourcifyChina provides comprehensive after-sales support, including machine installation, training, maintenance services, and spare parts.

7. How do I place an order?

You can place an order by contacting their sales team through email, phone, or their official website. Provide detailed information about your requirements for a tailored quote.

8. What shipping options are available?

SourcifyChina offers various shipping options, including sea freight, air freight, and express courier services. You can choose the one that best fits your timeline and budget.

9. Are there any warranties on the packing machines?

Yes, most packing machines come with a 1-year warranty covering parts and labor. Extended warranty options may also be available.

10. Can I visit the factory?

Yes, factory visits can be arranged. Contact the sales team to schedule a visit and see the production process firsthand.

For more details, you can visit SourcifyChina’s official website or contact their customer service team.