Sure, here’s a concise FAQ list for sourcing a packaging machine from SourcifyChina factory:

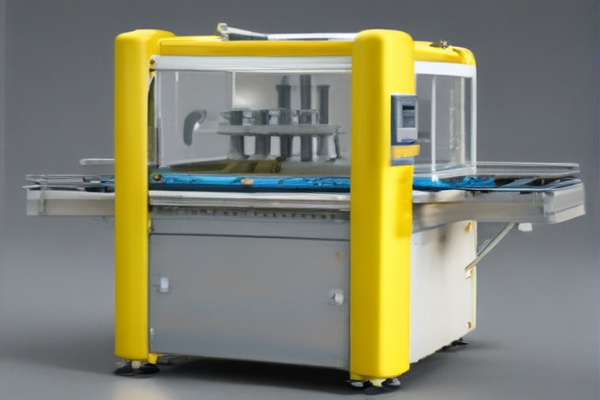

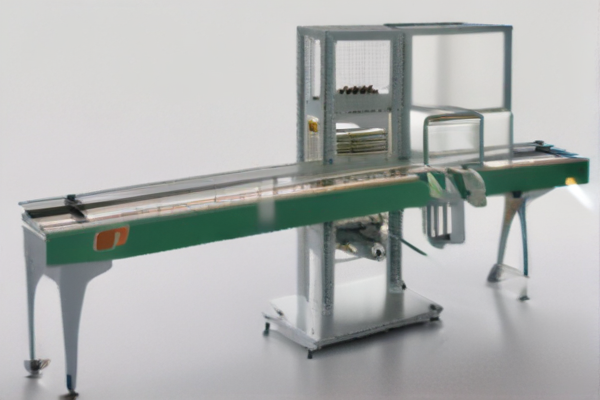

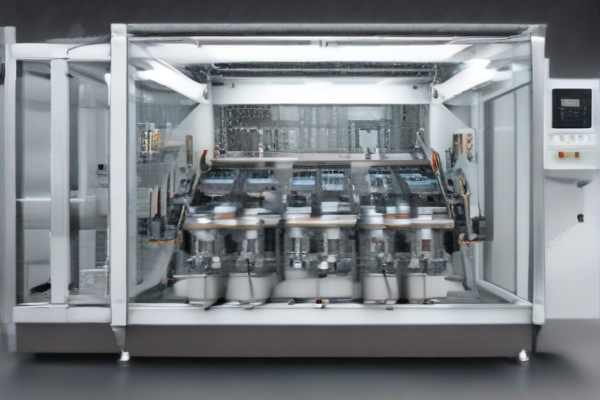

1. What types of packaging machines does SourcifyChina factory offer?

SourcifyChina factory offers a wide range of packaging machines including automatic, semi-automatic, vacuum, sealing, filling, and carton packaging machines.

2. How can I request a quotation for a packaging machine?

To request a quotation, you can visit the SourcifyChina website, select the desired machine, and fill out the contact form. Alternatively, you can email or call their sales department directly.

3. Are there customization options available for packaging machines?

Yes, SourcifyChina offers customization options based on your specific requirements, including machine size, capacity, and features.

4. What is the lead time for receiving a packaging machine?

The lead time varies depending on the model and customization requirements. Typically, it ranges from 4 to 8 weeks after order confirmation.

5. What are the payment terms for purchasing from SourcifyChina?

SourcifyChina generally requires a 30% deposit upon order confirmation, with the remaining 70% due prior to shipment. They accept wire transfers, letters of credit, and other secure payment methods.

6. Do you offer international shipping?

Yes, SourcifyChina provides international shipping services. They work with reputable logistics companies to ensure timely and safe delivery of your machinery.

7. Is there any after-sales service or support provided?

Yes, SourcifyChina offers comprehensive after-sales service including installation guidance, technical support, and spare parts supply. They also provide instructional material and remote assistance when needed.

8. What warranties are included with the packaging machines?

Most packaging machines from SourcifyChina come with a one-year warranty covering parts and labor. Extended warranty options may also be available.

9. How do I ensure the quality of the packaging machine?

SourcifyChina factory adheres to strict quality control standards, and they provide detailed product specifications and certification. You can also request inspection reports or third-party verification.

10. Can I visit the factory for an inspection?

Absolutely, SourcifyChina welcomes factory visits. You can schedule an appointment to tour the facility, meet the team, and see the production process firsthand.

I hope this helps! Feel free to reach out if you need more information.