Q: What is SourcifyChina factory?

A: SourcifyChina factory is a platform that connects you with reliable packaging machine manufacturers based in China, ensuring cost-effective and high-quality solutions.

Q: How do I start sourcing packaging machines from SourcifyChina factory?

A: To begin sourcing, visit the SourcifyChina factory website, create an account, and fill out a detailed sourcing request specifying your requirements and budget.

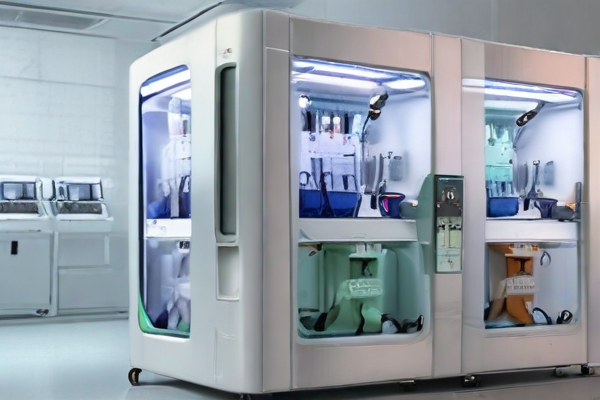

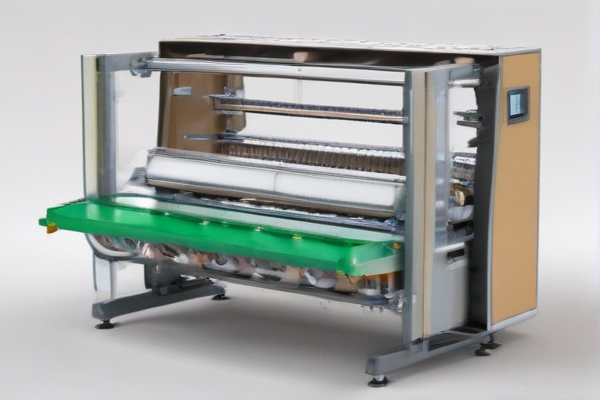

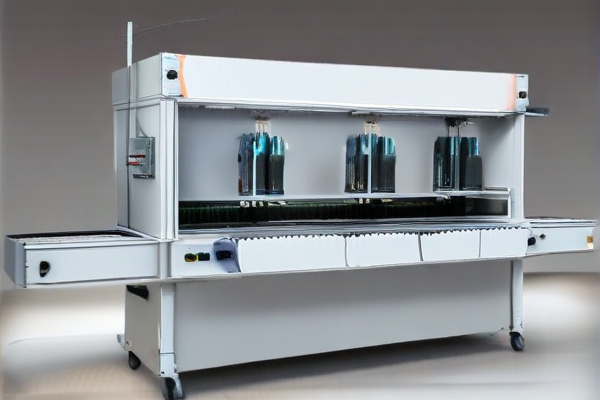

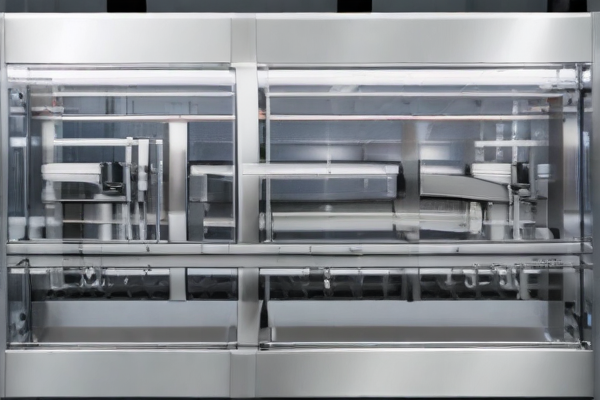

Q: What types of packaging machines can I source?

A: SourcifyChina factory offers a wide range of packaging machines, including filling machines, sealing machines, labeling machines, wrapping machines, and more.

Q: Are the manufacturers on SourcifyChina factory vetted?

A: Yes, SourcifyChina factory conducts thorough vetting processes to ensure that all listed manufacturers meet high standards of quality and reliability.

Q: Can I request custom packaging machines?

A: Absolutely. SourcifyChina factory facilitates custom requests to match specific requirements. Ensure you provide detailed specifications when submitting your sourcing request.

Q: What are the payment terms and methods available?

A: Payment terms and methods vary by manufacturer. Common options include wire transfers, credit cards, and letters of credit. Always confirm payment details with the manufacturer before proceeding.

Q: How long does the sourcing process take?

A: The timeline can vary based on your requirements and the complexity of the request. Initial quotes are typically provided within a few days, but custom orders may take longer.

Q: Can I visit the manufacturing facilities?

A: Yes, SourcifyChina factory can arrange visits to the manufacturing facilities upon request. This allows you to inspect the operations and ensure they meet your standards.

Q: What about shipping and logistics?

A: SourcifyChina factory offers assistance with shipping and logistics, ensuring that your machines are delivered safely and on time. You can also choose to handle shipping independently.

Q: How can I ensure the quality of the machines?

A: Quality assurance is paramount. SourcifyChina factory recommends getting samples, inspecting goods before shipment, and possibly hiring third-party inspection services.

Q: Are there after-sales services available?

A: Yes, many manufacturers offer after-sales support, including installation, training, and technical support. Confirm these services when finalizing your order.