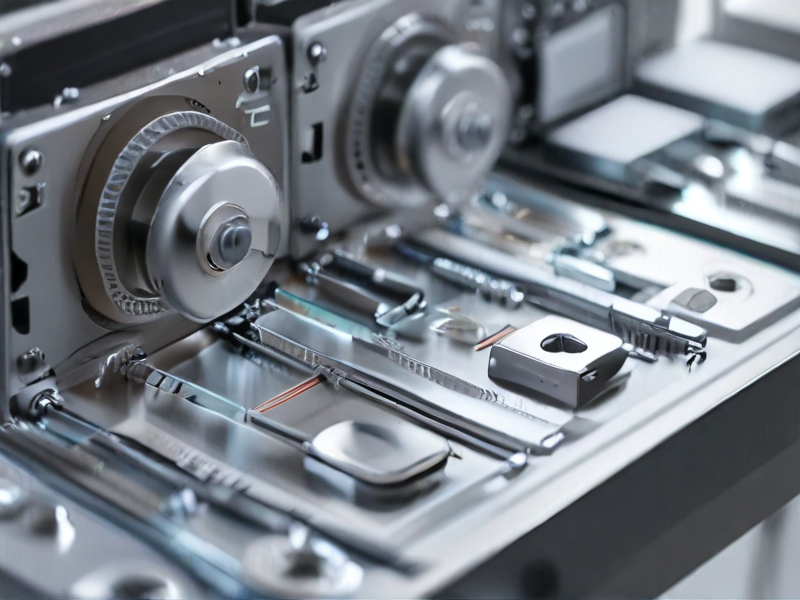

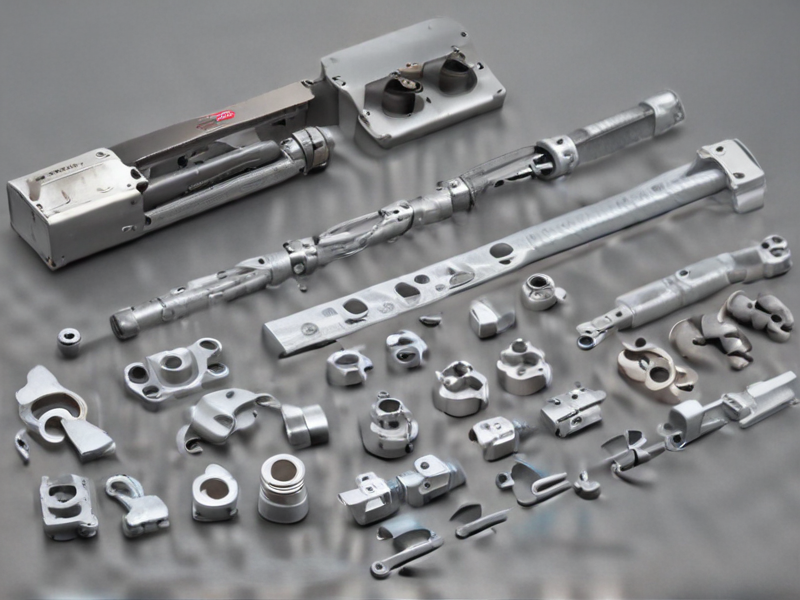

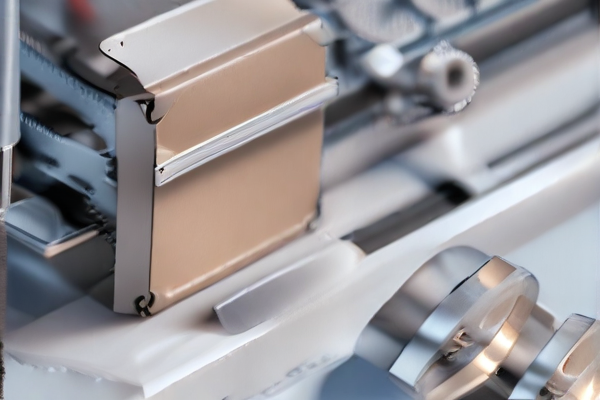

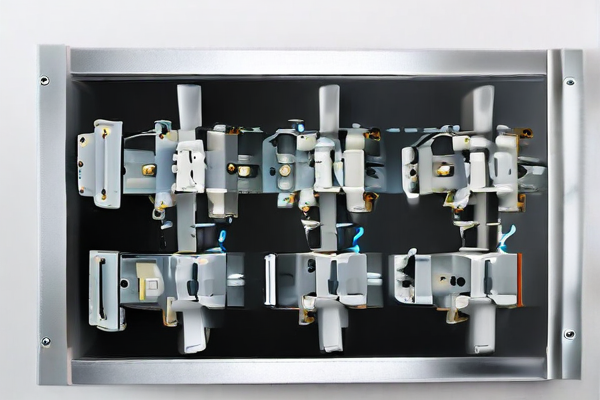

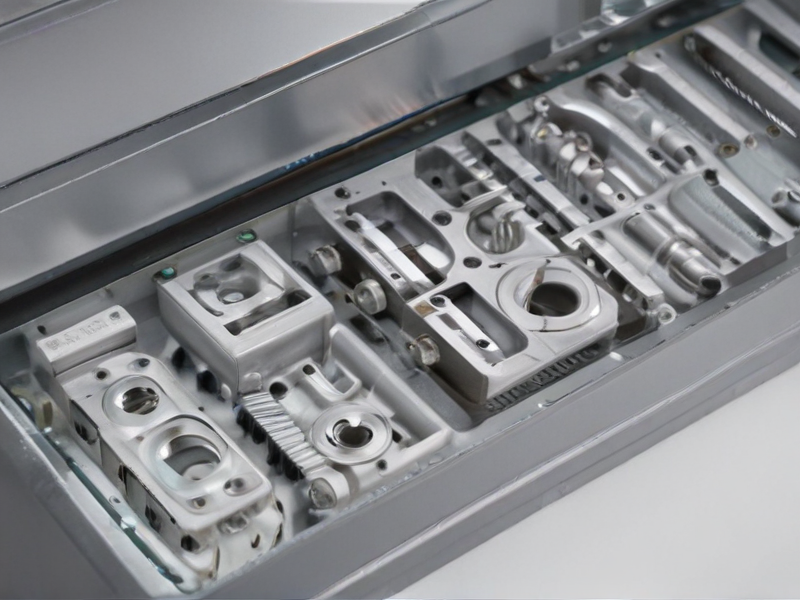

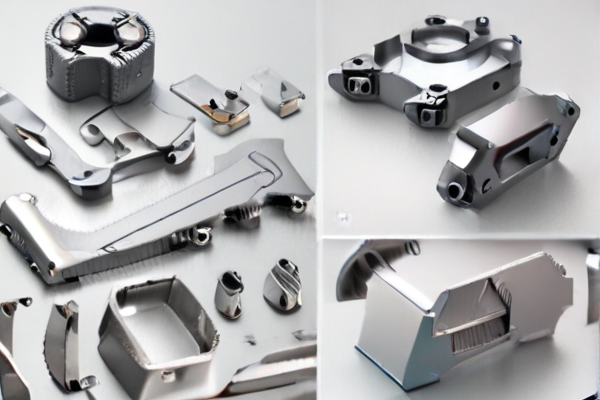

Packaging machine parts come in various types and configurations to meet specific industry needs. They enhance efficiency, reliability, and quality in packaging processes, catering to industries like food, pharmaceuticals, and consumer goods.

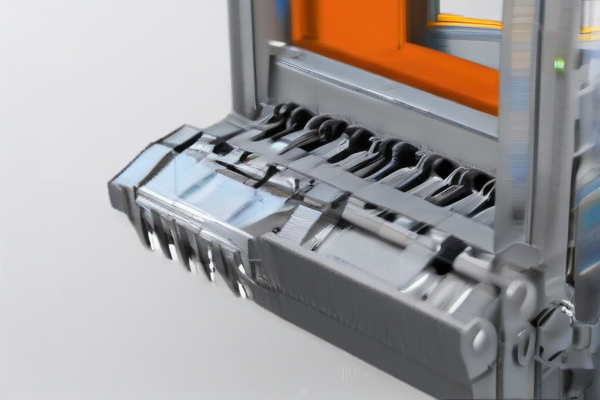

– Sealing Jaws: Crucial for heat sealing various packaging materials.

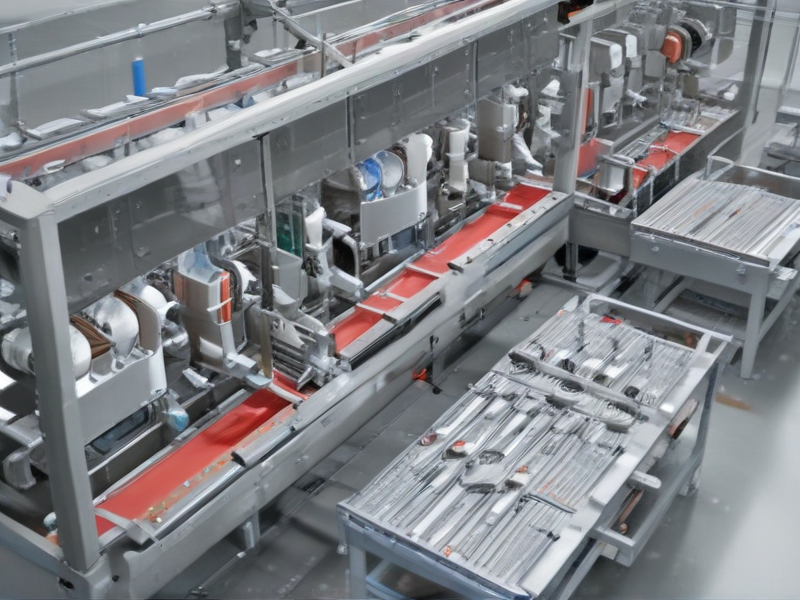

– Conveyors: Essential for moving products through the packaging process.

– Sensors: Detect product position and trigger automatic operations.

– Cutting Blades: Accurate cutting of packaging materials.

– Motors and Drives: Provide power and control to the machinery.

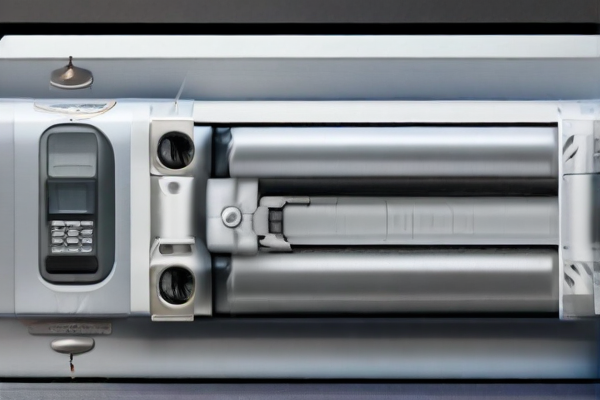

– Rollers: Facilitate smooth movement of materials.

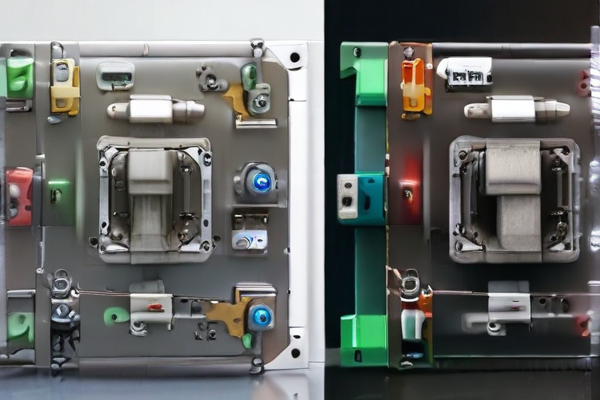

– Controllers: Manage machine functions for optimal performance.

– Feeding Systems: Ensure steady supply of packaging materials.

– Tensioners: Maintain appropriate tension in packaging films.

– Belt Assemblies: Transport products efficiently on production lines.

– Bearings: Reduce friction and wear in moving parts.

– Nozzles: Apply glue, ink, or other substances in precise amounts.

– Gearboxes: Modulate speed and torque in machinery.

– Pneumatic Components: Control air pressure and movement in the system.

– Heating Elements: Provide necessary heat for sealing and forming.

– Clamps: Hold components securely during operation.

– Hoppers: Feed bulk products consistently into the machine.

– Vacuum Systems: Remove air from packaging to preserve product freshness.

– Counters: Track the number of items processed.

– Alignment Guides: Ensure materials are correctly positioned.

– Lubrication Systems: Maintain optimal operation by reducing friction.

– Brakes: Control movement and halt operations when needed.

– Tension Control Systems: Adjust film tension for consistent packaging.

– Monitoring Systems: Track machine performance and output quality.

– Safety Guards: Protect operators from moving parts.

– Replacement Kits: Keep essential components on hand for quick fixes.

– Splicing Units: Handle film and material splices seamlessly.

– Electronics: Facilitate communication within the machine systems.

– Cooling Systems: Regulate temperature within the machine.

Employing the right mix of these components ensures improved reliability, efficiency, and production quality in packaging operations.