What is SourcifyChina Factory?

SourcifyChina Factory is a platform that connects businesses with dependable Chinese manufacturers for various products, including packaging machines. They offer a range of services from product sourcing to quality control.

How do I find a packaging machine manufacturer on SourcifyChina Factory?

To find a packaging machine manufacturer, simply visit their website, use the search function to look for “packaging machines,” and browse through the listed manufacturers. You can refine your search using filters like machine type, capacity, and price range.

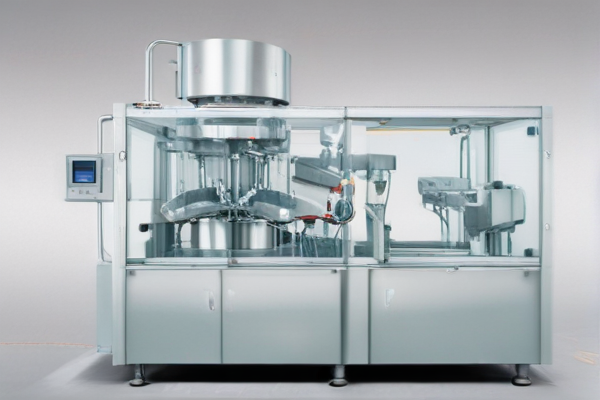

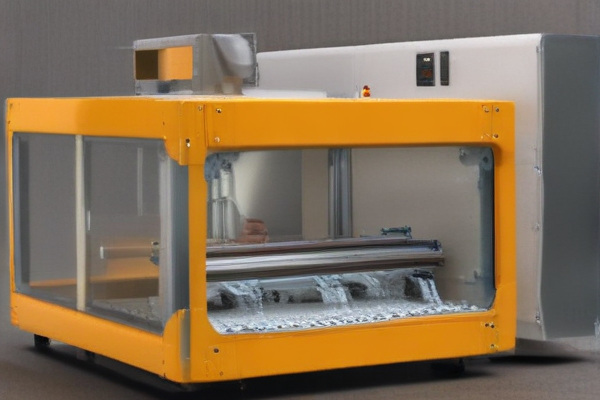

What types of packaging machines can I source?

You can source various types of packaging machines including, but not limited to, filling machines, sealing machines, labeling machines, shrink wrap machines, and automated packaging systems.

Is there a minimum order quantity (MOQ) for packaging machines?

The MOQ varies by manufacturer. Some might have a low MOQ for standard models, while others may require larger orders, especially for custom machines. Always check with the individual manufacturer for their specific MOQ policies.

Can I request samples or a demo of the packaging machine?

Yes, many manufacturers provide samples or demos upon request. Be prepared that samples may include shipping costs or a minimal fee. Demos can often be arranged via video conferencing or factory visits if feasible.

What kind of support or warranty is offered by the manufacturers?

Support and warranty terms vary between manufacturers. Commonly, they offer technical support, spare parts, and a warranty period ranging from one to two years. Always clarify these details before finalizing your purchase.

How long does it take to manufacture and deliver a packaging machine?

Lead times can vary based on the machine’s complexity, customizations, and the manufacturer’s production schedule. Generally, it takes anywhere from a few weeks to several months. Shipping times will also add to the overall delivery period.

Can I customize the packaging machine according to my specific needs?

Yes, many manufacturers on SourcifyChina Factory offer customization options. You can discuss your requirements with them to modify features, functionalities, or even the machine design to suit your needs.

Are the manufacturers on SourcifyChina Factory verified?

Yes, SourcifyChina Factory takes measures to verify the manufacturers they list, providing a layer of trust and reliability for businesses seeking to find genuine and competent suppliers.

How do I handle payment transactions?

Payment terms vary by manufacturer but typically include methods like bank transfers, Letters of Credit (LC), or payment through the SourcifyChina Factory platform.