What types of packing machines do you manufacture at SourcifyChina Factory?

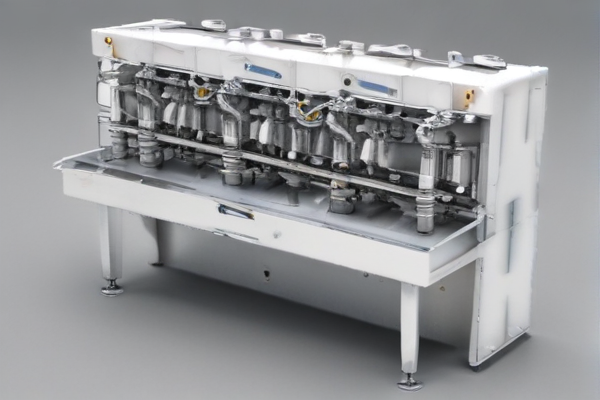

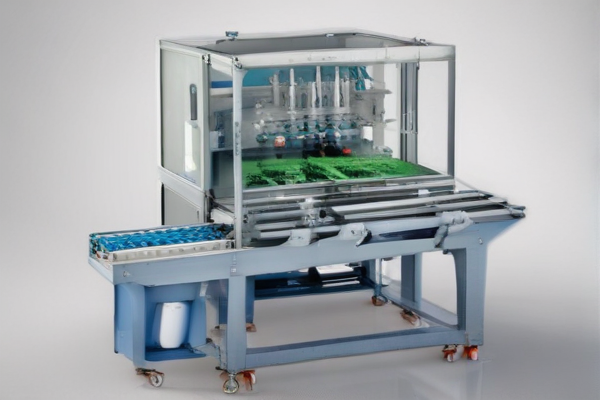

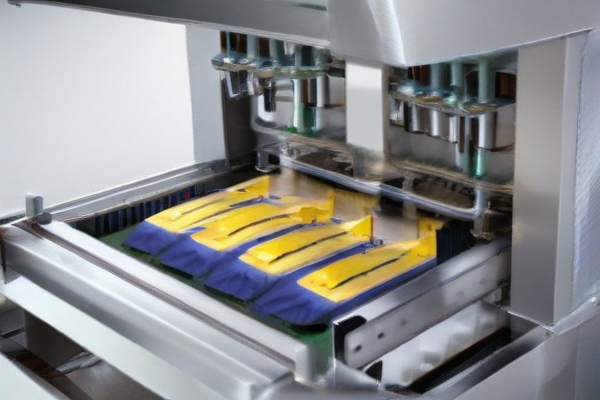

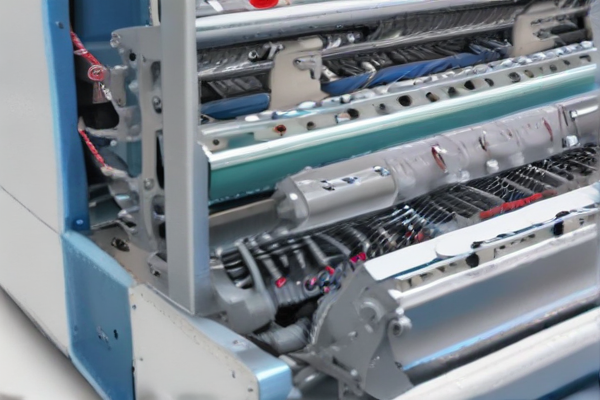

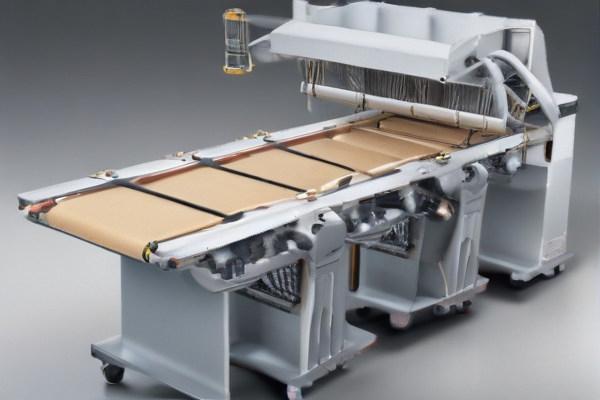

We manufacture a variety of packing machines, including automatic filling machines, sealing machines, labeling machines, and multi-functional packing systems. These machines cater to different industries such as food and beverages, pharmaceuticals, cosmetics, and electronics.

How does SourcifyChina ensure the quality of its packing machines?

We follow stringent quality control procedures at every stage of the manufacturing process. This includes raw material inspection, in-process quality checks, and final product testing. Our factory is ISO certified, ensuring adherence to international quality standards.

What materials are used in the construction of your packing machines?

Our packing machines are primarily constructed using high-grade stainless steel and other durable materials. This ensures longevity, reliability, and resistance to corrosion, making them suitable for various industrial applications.

Do you offer customization options for your packing machines?

Yes, we offer customization options to meet specific client requirements. Whether you need custom dimensions, operational features, or integrations with existing systems, our engineering team is equipped to deliver tailored solutions.

What kind of after-sales support does SourcifyChina provide?

We offer comprehensive after-sales support, including installation assistance, training for your staff, and ongoing maintenance services. We also provide a warranty period during which our technicians are available for any issues that may arise.

Can I visit the factory to inspect the machines before purchase?

Absolutely! We welcome clients to visit our factory to inspect the machines, meet our engineers, and see our quality assurance processes in person. Please arrange a visit by contacting our sales team.

What is the lead time for manufacturing and delivering packing machines?

The lead time varies depending on the complexity and customization of the machine. On average, it takes about 6-8 weeks from order confirmation to delivery. We strive to meet deadlines and keep our clients informed throughout the process.

Are your packing machines energy-efficient?

Yes, our packing machines are designed with energy efficiency in mind. We use modern technology and smart engineering to minimize energy consumption, which helps reduce operational costs and environmental impact.

How do you handle international shipping and logistics?

We have established partnerships with reliable logistics companies to ensure timely and safe delivery of our machines worldwide. We handle all necessary documentation and comply with international shipping regulations to make the process smooth for our clients.