Sure! Here’s a compact FAQ for sourcing a pallet wrapping machine from SourcifyChina factory:

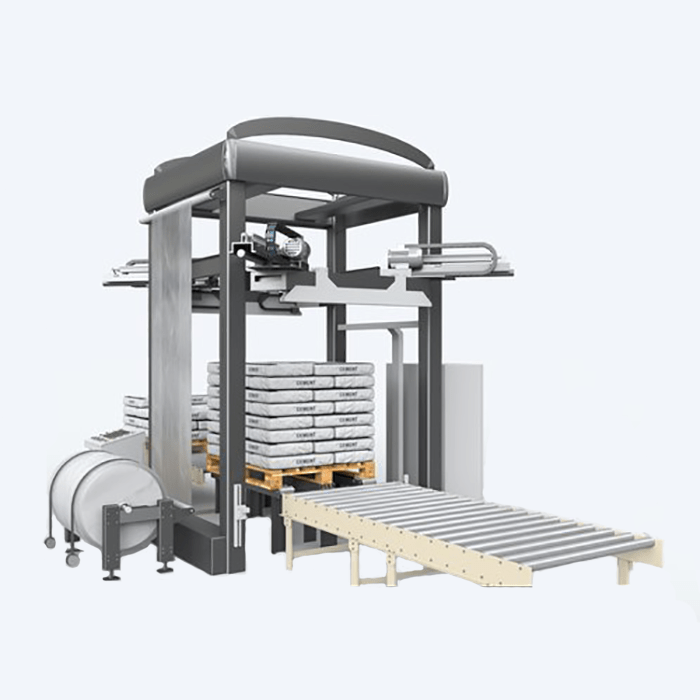

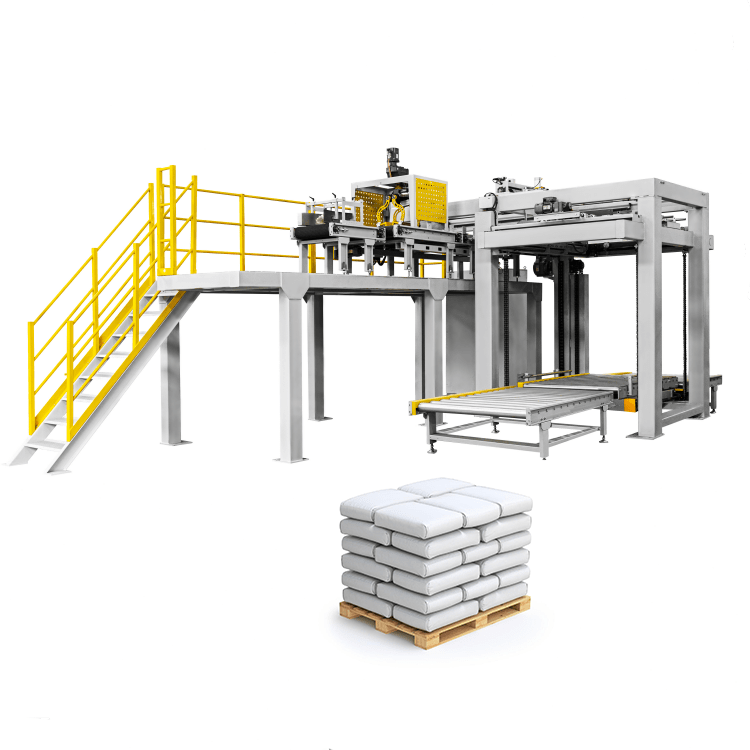

Q: What types of pallet wrapping machines does SourcifyChina offer?

A: SourcifyChina provides a range of pallet wrapping machines including manual, semi-automatic, and fully automatic models, catering to diverse packaging needs.

Q: Can I customize the pallet wrapping machine according to my needs?

A: Yes, SourcifyChina offers customization options to meet specific requirements such as size, wrap settings, and additional features like automated film cutting.

Q: How do I request a quote?

A: You can request a quote by visiting SourcifyChina’s website, filling out the inquiry form, or contacting their sales team directly via email or phone.

Q: What is the typical lead time for a pallet wrapping machine?

A: The lead time varies depending on the model and customization options, typically ranging from 15 to 45 days.

Q: Are there warranties and after-sales support available?

A: Yes, SourcifyChina provides warranties on their machines and offers comprehensive after-sales support, including installation guidance and maintenance services.

Q: What payment methods are accepted?

A: SourcifyChina accepts various payment methods including T/T (Telegraphic Transfer), L/C (Letter of Credit), and sometimes PayPal or credit cards.

Q: Can I visit the factory for an inspection before purchasing?

A: Yes, SourcifyChina welcomes factory visits. You can schedule an appointment with their team to inspect the production facilities and machines.

Q: How is shipping handled?

A: SourcifyChina coordinates shipping through reliable carriers and offers various shipping options like sea, air, and express to meet different needs.

Q: Are installation and training services available?

A: Yes, SourcifyChina can arrange installation and training services to ensure proper setup and operation of the machine.

Q: What certifications do the pallet wrapping machines have?

A: The machines typically come with CE and ISO certifications, ensuring compliance with international quality and safety standards.

Q: How can I get technical support if needed?

A: Technical support is available via email, phone, and sometimes on-site visits depending on your location and the nature of the issue.