Certainly! Here is a concise list of frequently asked questions (FAQ) with answers for sourcing a palletizer system from SourcifyChina factory:

1. What types of palletizer systems does SourcifyChina offer?

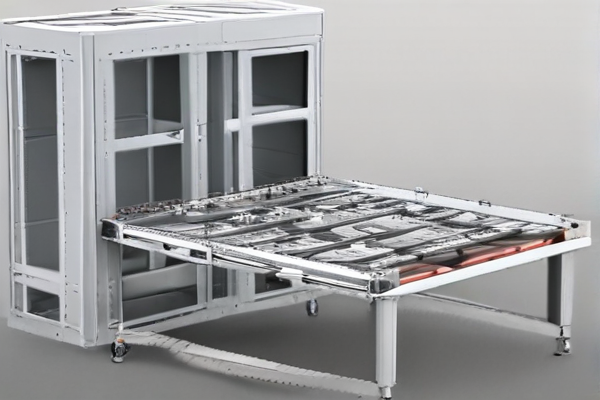

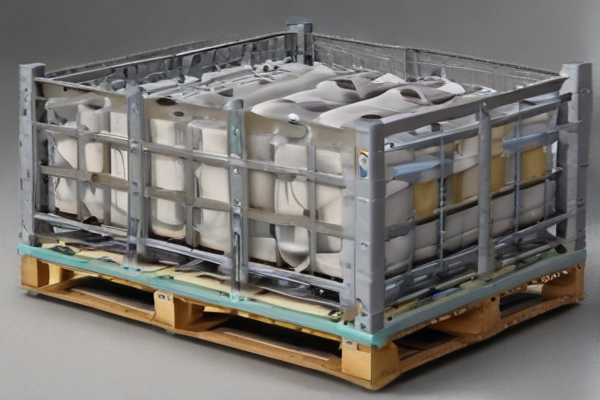

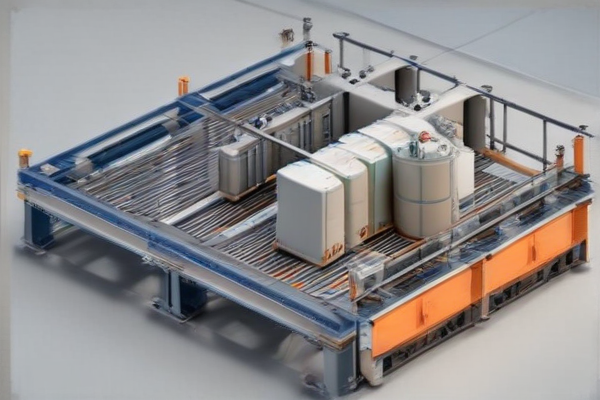

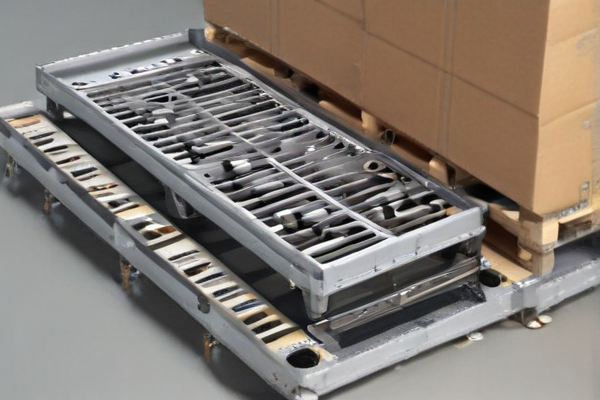

SourcifyChina offers various types of palletizer systems including robotic palletizers, automatic palletizers, and semi-automatic palletizers. Each type can be customized based on specific industry needs and operational requirements.

2. How can I get a quotation for a palletizer system?

You can request a quotation by visiting our website and filling out the inquiry form, or by directly contacting our sales team via email or phone. Please provide detailed requirements to receive an accurate quote.

3. What is the lead time for a palletizer system order?

The lead time varies depending on the complexity and customization of the palletizer system. Generally, it ranges from 6 to 12 weeks. For exact timelines, please consult with our sales representative.

4. Do you provide installation and training services?

Yes, SourcifyChina provides comprehensive installation services and on-site training for your staff to ensure smooth operation and maintenance of the palletizer system.

5. What are the payment terms?

Our standard payment terms are 30% deposit upon order confirmation, with the balance due before shipment. We can also discuss and agree on other payment arrangements for bulk orders or long-term partnerships.

6. Are your palletizer systems compliant with international safety standards?

Absolutely. All our palletizer systems comply with international safety standards such as CE and ISO, ensuring reliable and safe operation in your facility.

7. Can I customize the palletizer system to fit my specific needs?

Yes, customization is one of our key strengths. We work closely with our clients to design and manufacture palletizer systems tailored to meet their specific operational requirements and preferences.

8. What after-sales support do you offer?

SourcifyChina offers robust after-sales support including a warranty period, spare parts supply, technical support, and regular maintenance services to ensure your palletizer system runs efficiently.

9. How do I verify the quality of your palletizer systems?

You are welcome to visit our factory for an on-site inspection. Additionally, we provide detailed quality reports and certifications upon request to ensure complete transparency and assurance of quality.

10. Do you ship internationally?

Yes, we ship our palletizer systems internationally. We work with reliable logistics partners to ensure timely and safe delivery to your location.