Sure, here is a compact list of FAQs about sourcing a palletizing machine from SourcifyChina Factory:

Q1: What types of palletizing machines do you offer?

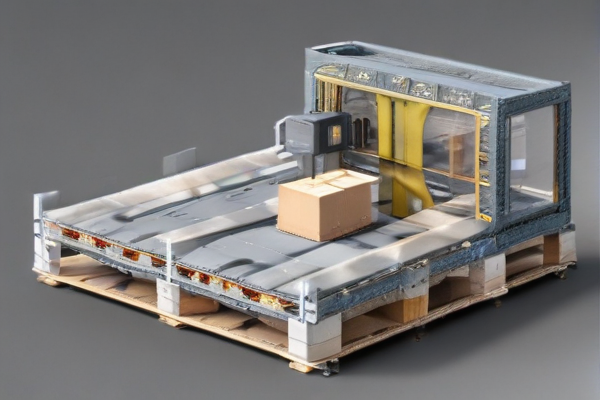

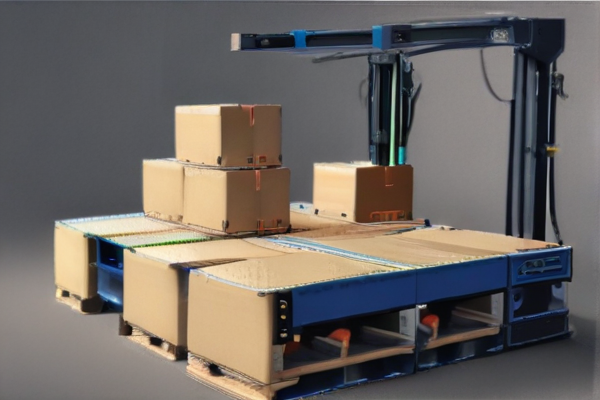

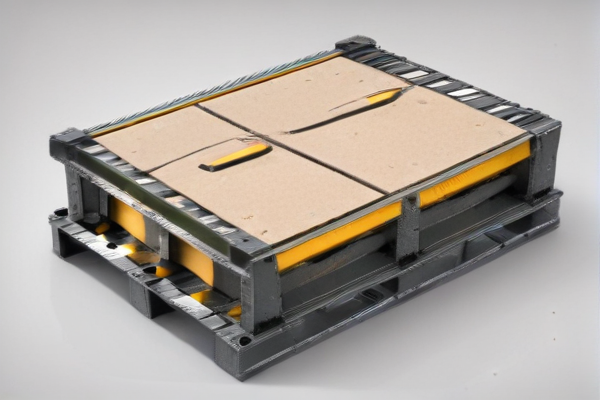

A1: SourcifyChina offers various types of palletizing machines, including robotic palletizers, automatic palletizers, and semi-automatic palletizers, to cater to diverse industrial needs.

Q2: What is the lead time for delivery?

A2: The typical lead time for delivery ranges from 6 to 8 weeks, depending on customization requirements and order volume.

Q3: Can the palletizing machines be customized?

A3: Yes, SourcifyChina provides customization based on your specific requirements, such as machine size, handling capacity, and integration with existing systems.

Q4: What are the payment terms?

A4: Our standard payment terms are 30% advance payment and the remaining 70% before shipment. However, we are open to discussing flexible payment options.

Q5: Do you provide installation and training services?

A5: Yes, we offer on-site installation and training services to ensure your team can operate the equipment efficiently and safely.

Q6: What is the warranty period?

A6: SourcifyChina provides a 1-year warranty on all our palletizing machines, covering parts and labor for any manufacturing defects.

Q7: How do you handle after-sales support?

A7: We offer comprehensive after-sales support, including remote troubleshooting, on-site repairs, and maintenance services to ensure smooth operation.

Q8: Are the machines compliant with international standards?

A8: Yes, all our palletizing machines are designed to meet international safety and quality standards, such as CE and ISO certifications.

Q9: What are the shipping arrangements?

A9: We handle all shipping logistics, including packaging, customs clearance, and delivery to your site. You can choose either FOB or CIF terms based on your preference.

Q10: How can I get a quotation?

A10: You can get a detailed quotation by contacting our sales team with your specific requirements, including type of machine, volume, and customization needs.

This concise FAQ should help address some of the most common inquiries about sourcing palletizing machines from SourcifyChina Factory.