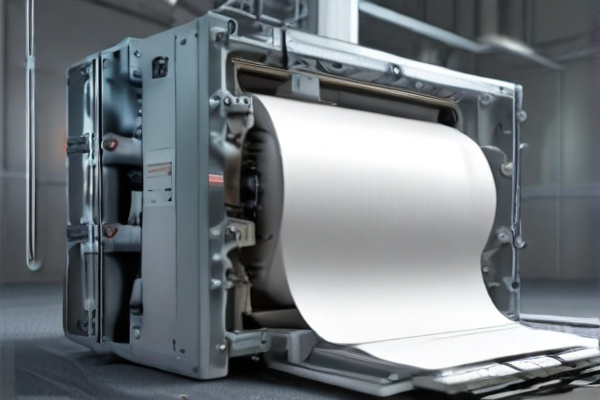

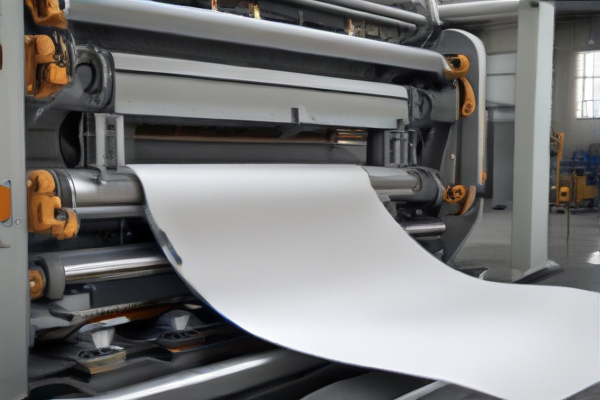

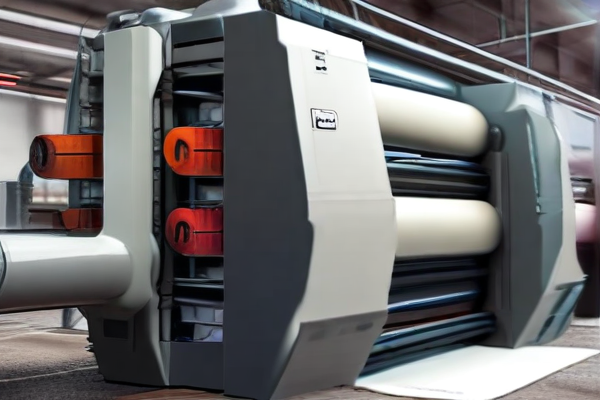

Sourcing paper converting machinery from SourcifyChina factory requires a strategic approach to ensure you get high-quality equipment at competitive prices. Here are some tips:

1. Research and Identify Needs:

– Clearly define the specifications, capacity, and features you need in the machinery.

– Understand your production requirements to choose the right type of machinery, such as slitting, rewinding, or folding machines.

2. Supplier Verification:

– Check SourcifyChina’s factory credentials, certifications, and track record.

– Read reviews and testimonials from other clients to gauge reputation.

3. Request Detailed Quotations:

– Obtain a comprehensive quote, including machine cost, shipping, installation, and training.

– Compare prices while considering the quality and after-sales services.

4. Quality Assurance:

– Ask for detailed information on the manufacturing process and quality control measures.

– Request product samples or arrange for a factory visit if possible.

5. Negotiate Terms:

– Negotiate payment terms and conditions, ensuring favorable and secure agreements.

– Discuss warranty terms and after-sale support, including spare parts availability.

6. Shipping and Logistics:

– Clarify Incoterms (e.g., FOB, CIF) and confirm who handles customs clearance.

– Ensure proper packaging to prevent damage during transit.

7. After-Sales Service:

– Confirm the availability of installation guides, manuals, and technical support.

– Ensure there is a mechanism for prompt service or parts replacement if needed.

8. Legal Compliance:

– Verify that the machinery complies with your country’s import regulations and standards.

– Ensure all necessary documentation, including invoices, certificates, and shipping documents, are in order.

By following these steps, you can effectively source paper converting machinery from SourcifyChina factory, ensuring both quality and efficiency in your procurement process.