Sure! Here is a list of FAQs with answers related to the “peanut butter filling machine quality work from SourcifyChina factory”:

1. What quality standards does the peanut butter filling machine from SourcifyChina factory adhere to?

The peanut butter filling machines from SourcifyChina factory comply with ISO 9001 quality management standards and are built following GMP guidelines to ensure top quality and safety.

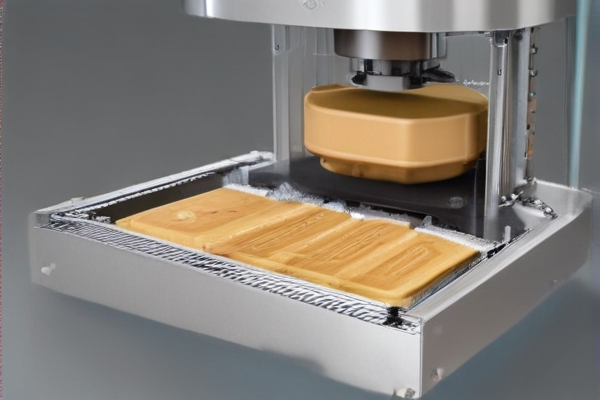

2. What materials are used in the construction of the filling machine?

The filling machines are constructed using high-grade stainless steel, which is food-safe, corrosion-resistant, and easy to clean, ensuring durability and hygiene.

3. Does the machine support different types of peanut butter consistency?

Yes, our peanut butter filling machines are designed to handle a variety of consistencies, from smooth to chunky peanut butter, with adjustable settings for precision.

4. What is the filling capacity of the machine?

The filling capacity can range from 100ml to 5 liters, depending on the specific model and configuration, making it suitable for small to large scale production.

5. Are the machines easy to clean and maintain?

Absolutely, our machines feature detachable parts and smooth surfaces, making them very easy to clean. They also require minimal maintenance, enhancing operational efficiency.

6. How accurate is the filling process?

Our machines utilize advanced volumetric and piston filling mechanisms that ensure high precision, with an accuracy rate of ±1%.

7. Is there technical support and warranty available?

Yes, SourcifyChina offers comprehensive technical support and a one-year warranty for all filling machines. Extended support and maintenance plans are also available.

8. Can the machine be customized?

Yes, customization options are available to meet specific production requirements, including changes in filling speed, nozzle type, and automated integration.

9. What is the delivery time for the machine?

Standard delivery time is typically 4-6 weeks from the order date, but this can vary based on customization and order volume.

10. How do I place an order or inquire further?

You can contact us through our website, email, or phone. Our customer service team will assist you with any inquiries and guide you through the ordering process.

This concise FAQ should address common questions while keeping the information clear and informative.