Sure, here’s a brief FAQ for sourcing pharma packaging machines from SourcifyChina factory:

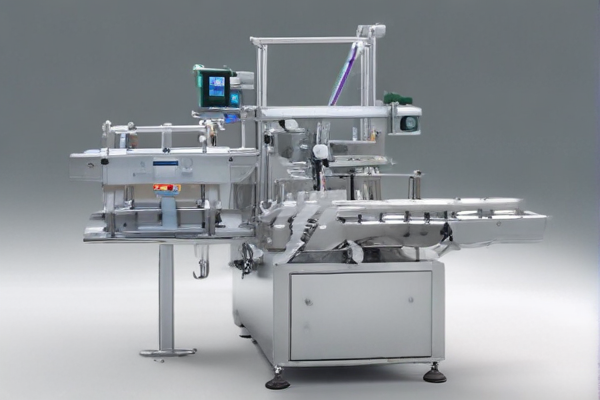

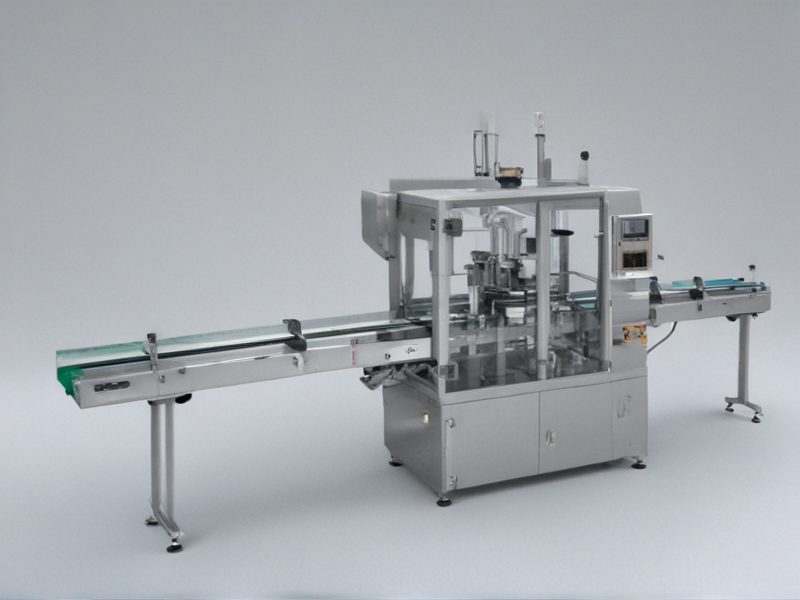

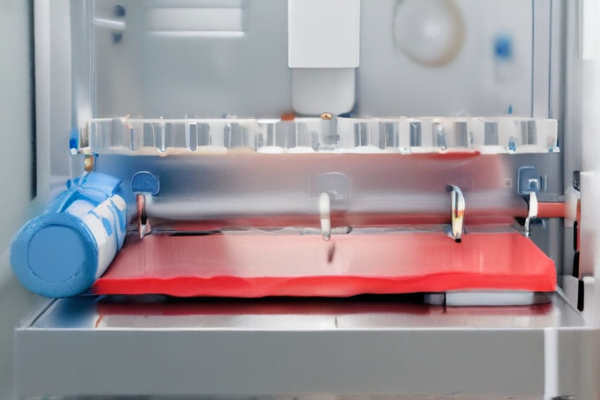

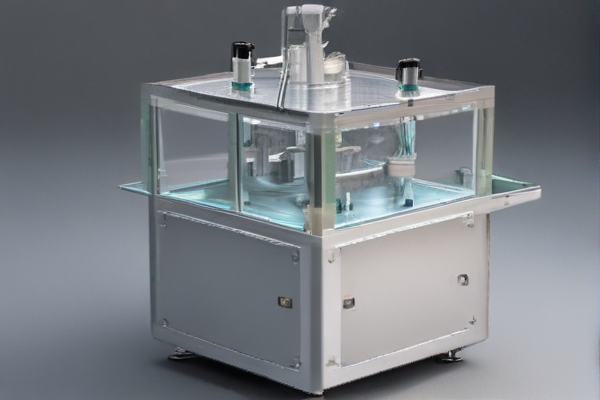

Q: What types of pharma packaging machines does SourcifyChina offer?

A: SourcifyChina provides a wide range of pharma packaging machines, including blister packaging machines, bottle filling machines, strip packaging machines, and carton packaging machines.

Q: Are the machines compliant with regulatory standards?

A: Yes, our machines comply with international regulatory standards such as GMP, CE, and ISO, ensuring they meet quality and safety requirements.

Q: Can I customize the packaging machines according to my needs?

A: Absolutely! We offer customization services to tailor the machines to your specific requirements, such as size, capacity, and functionality.

Q: What is the typical lead time for an order?

A: The lead time varies based on the complexity of the machine and current order volume but typically ranges from 4 to 12 weeks.

Q: What kind of after-sales support do you provide?

A: We offer comprehensive after-sales support, including installation assistance, training, and maintenance services, as well as a warranty for your peace of mind.

Q: How can I request a quote?

A: You can request a quote by visiting our website and filling out the inquiry form, or by contacting our sales team directly via email or phone.

Q: What payment terms are available?

A: We accept various payment terms, including T/T, L/C, and other negotiable terms based on the order value and client relationship.

Q: Can I visit SourcifyChina’s factory for an inspection?

A: Yes, we welcome clients to visit our factory for an inspection. Please contact us in advance to arrange your visit.

Q: Do you provide samples before placing a bulk order?

A: Yes, we can arrange for sample machines or packaging tests on request to ensure the machine meets your requirements.

Q: What shipping options are available?

A: We offer multiple shipping options, including sea freight, air freight, and express courier services, depending on your urgency and budget.