Sure, here’s a concise FAQ about sourcing a pharma packaging machine from SourcifyChina factory:

1. What types of pharma packaging machines does SourcifyChina offer?

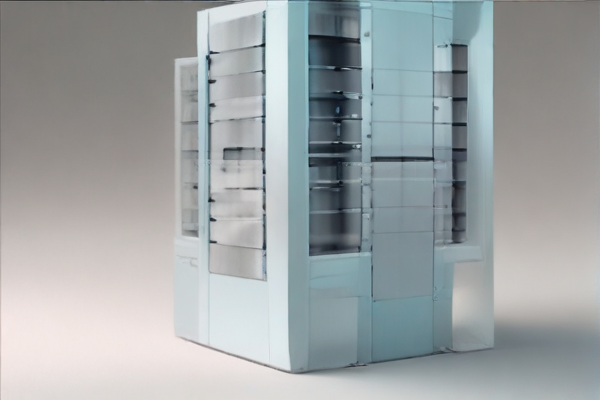

SourcifyChina offers a wide range of pharma packaging machines including blister packaging machines, strip packaging machines, cartoning machines, and bottle filling and capping machines.

2. Are the machines compatible with international standards?

Yes, all machines are designed and manufactured in compliance with international standards, such as GMP (Good Manufacturing Practice) and FDA (Food and Drug Administration) guidelines.

3. Can SourcifyChina customize machines to meet specific requirements?

Absolutely. SourcifyChina provides customization options to meet unique specifications or requirements. You can discuss your needs with their technical team.

4. What is the lead time for ordering a machine?

Lead times typically range from 4 to 8 weeks, depending on the complexity of the machine and customization requirements.

5. What warranty and after-sales services are provided?

SourcifyChina offers a 12-month warranty on all machines. Additionally, they provide after-sales services such as installation support, training, and maintenance.

6. How is the quality of the machines ensured?

Quality assurance is a priority at SourcifyChina. Machines undergo rigorous quality checks, including performance tests and safety inspections, before being shipped.

7. Is technical support available post-purchase?

Yes, SourcifyChina provides comprehensive technical support post-purchase, including online and on-site assistance.

8. What payment methods are accepted?

Accepted payment methods include bank transfers (T/T), letters of credit (L/C), and, in some cases, payment through recognized third-party platforms.

9. Does SourcifyChina assist with shipping and import documentation?

Yes, SourcifyChina assists with shipping logistics and ensures all necessary documentation is provided for smooth customs clearance.

10. Can I visit the factory to inspect the machines before purchase?

Yes, factory visits can be arranged. You can schedule an appointment to inspect the machines and meet the team.

For any further questions, you may contact SourcifyChina directly.