FAQ for Manufacturing Pharmaceutical Packaging Machine Quality Work from SourcifyChina Factory

1. What is the quality standard for pharmaceutical packaging machines from SourcifyChina factory?

Our pharmaceutical packaging machines adhere to international standards such as ISO 9001, GMP, and FDA regulations, ensuring high quality and reliability.

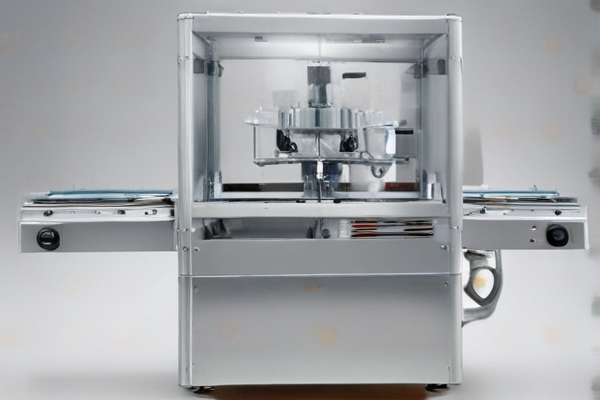

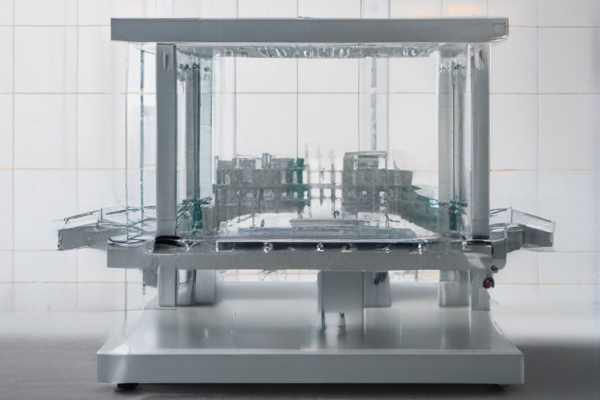

2. What materials are used in the manufacturing of these machines?

We use high-grade stainless steel and other industry-approved materials to ensure durability and compliance with hygiene standards.

3. Can SourcifyChina provide custom packaging solutions?

Yes, we offer customized solutions tailored to meet the specific needs of our clients in the pharmaceutical industry.

4. How do you ensure the machines meet regulatory requirements?

Our machines undergo rigorous testing and validation processes to meet global regulatory standards, including GMP and FDA guidelines.

5. What is the typical lead time for manufacturing a pharmaceutical packaging machine?

The lead time generally ranges from 8 to 12 weeks, depending on the complexity and customization requirements of the project.

6. Does SourcifyChina offer after-sales service and maintenance?

Yes, we provide comprehensive after-sales service, including installation, training, and maintenance support to ensure the optimal performance of our machines.

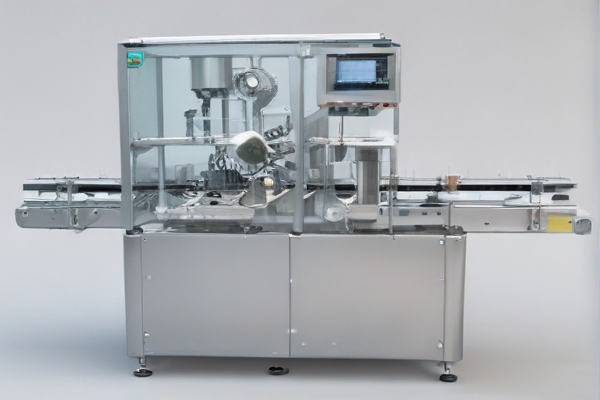

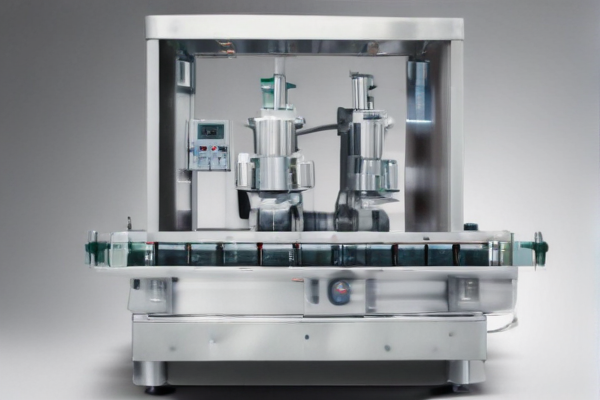

7. What type of packaging solutions does SourcifyChina offer?

We offer a range of packaging solutions such as blister packaging, bottle filling, and cartoning, all designed to meet pharmaceutical standards.

8. Are the machines compatible with different types of pharmaceutical products?

Yes, our machines are versatile and can handle various forms of pharmaceutical products including tablets, capsules, liquids, and powders.

9. How do you handle quality control during the manufacturing process?

We implement strict quality control measures, including regular inspections and testing at each stage of the manufacturing process to ensure the highest quality.

10. Can I visit the SourcifyChina factory to see the manufacturing process?

Absolutely, we welcome clients to visit our factory to observe our manufacturing process and quality control measures in action. Please schedule your visit in advance.