Certainly! Here is a FAQ list for sourcing pharmaceutical packaging machines from SourcifyChina factory, with each question in bold:

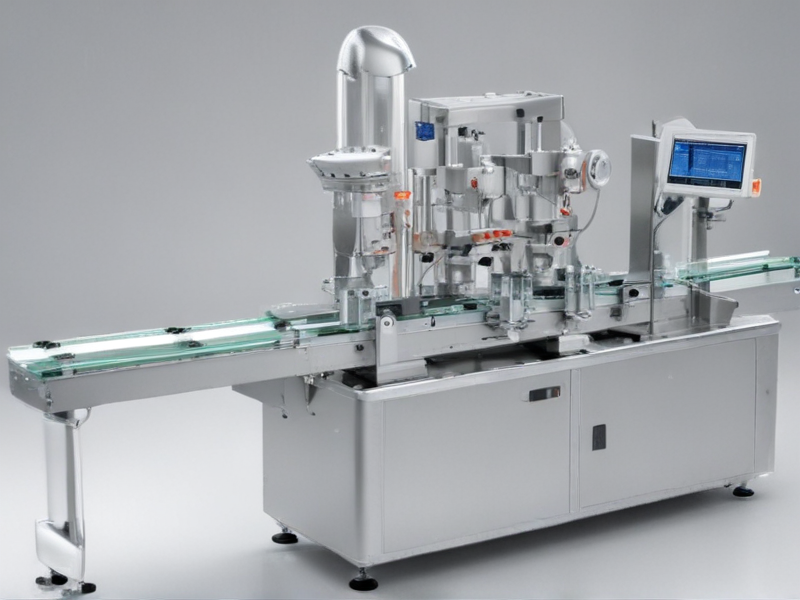

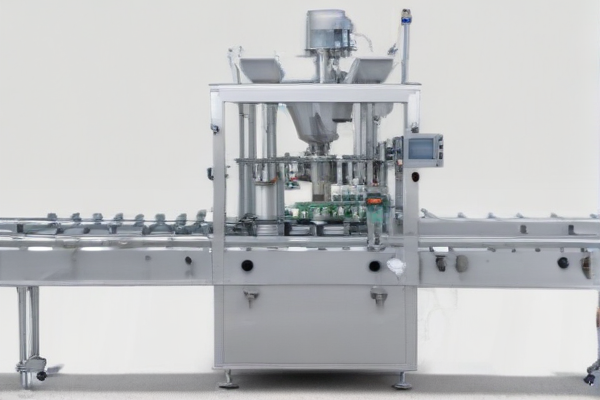

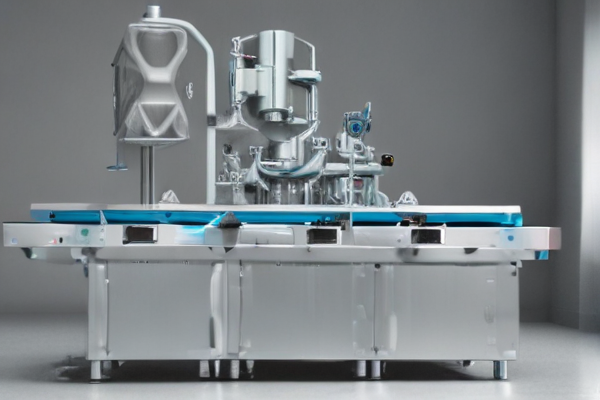

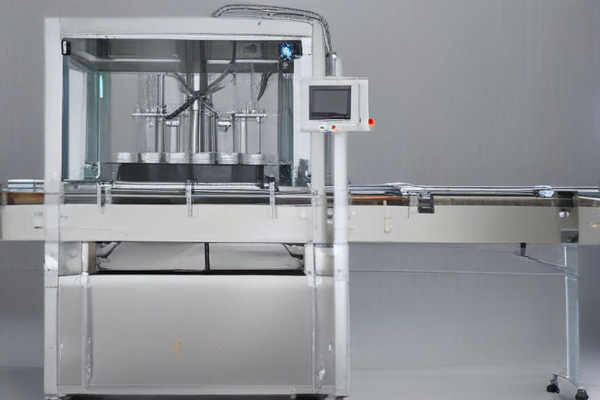

Q: What types of pharmaceutical packaging machines does SourcifyChina offer?

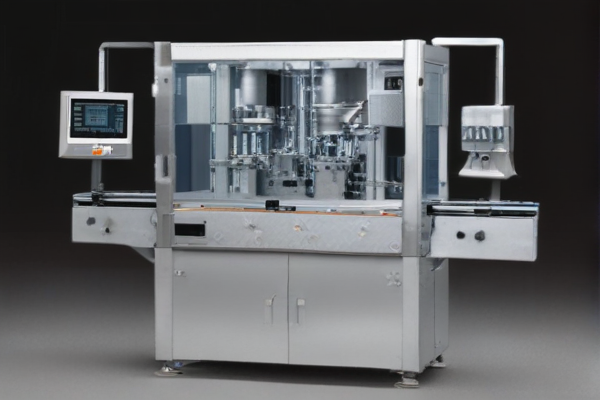

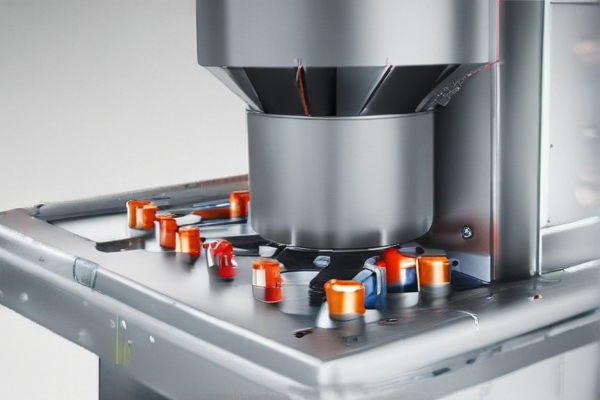

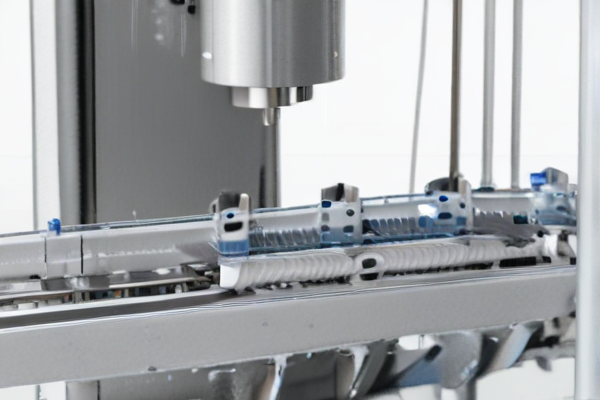

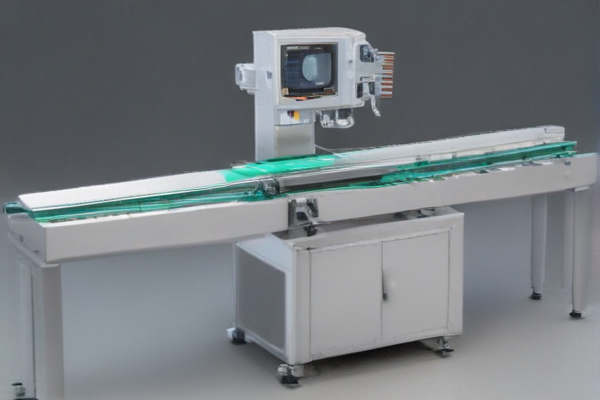

A: SourcifyChina offers a wide range of pharmaceutical packaging machines including blister packaging machines, bottle filling machines, strip packaging machines, tube filling machines, and labeling machines.

Q: Are the machines compliant with international quality standards?

A: Yes, all machines from SourcifyChina adhere to international quality standards such as ISO, GMP, and CE. This ensures the highest safety and quality in pharmaceutical packaging.

Q: What is the lead time for delivery?

A: The typical lead time for delivery is between 6 to 8 weeks, depending on the complexity and customization of the machine ordered.

Q: Do you provide installation and training services?

A: Yes, SourcifyChina provides comprehensive installation and training services. Expert technicians are available to assist with the setup and to train your staff on operating the machines.

Q: What after-sales support is available?

A: We offer robust after-sales support, including maintenance services, spare parts availability, and technical assistance to ensure smooth operation of your equipment.

Q: Can the machines be customized?

A: Absolutely. SourcifyChina can tailor machines to meet specific requirements of your pharmaceutical production line. Customizations can be discussed and implemented based on your needs.

Q: What are the payment terms?

A: Payment terms are flexible and can be negotiated. Typically, an initial deposit is required with the balance payable upon delivery.

Q: How do I request a quotation?

A: You can easily request a quotation by visiting our website and filling out the inquiry form, or by contacting our sales team directly via email or phone.

Q: Is it possible to visit your factory before making a purchase?

A: Yes, we welcome potential customers to visit our factory for a comprehensive tour and direct discussions with our engineering team.

Q: What are the warranty terms for the machines?

A: Machines typically come with a one-year warranty, covering parts and labor. Extended warranties can also be negotiated.

This concise list should cover the most common questions potential clients have about sourcing pharmaceutical packaging machines from SourcifyChina.