Sure, here is a list of FAQs with answers for the manufacturing of “pill packing machines” from SourcifyChina factory:

Q1: What materials are used in the construction of the pill packing machines?

A1: SourcifyChina utilizes high-quality stainless steel and FDA-approved components, ensuring durability and compliance with health standards.

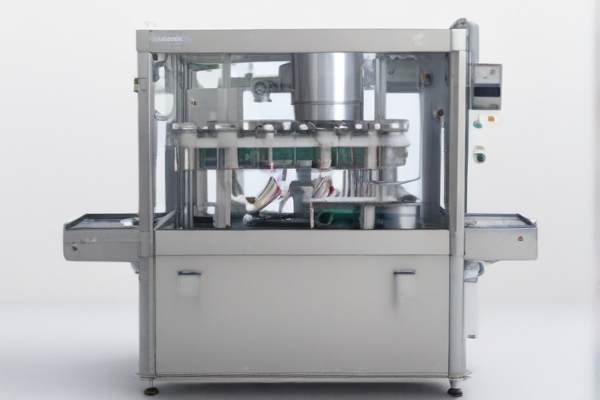

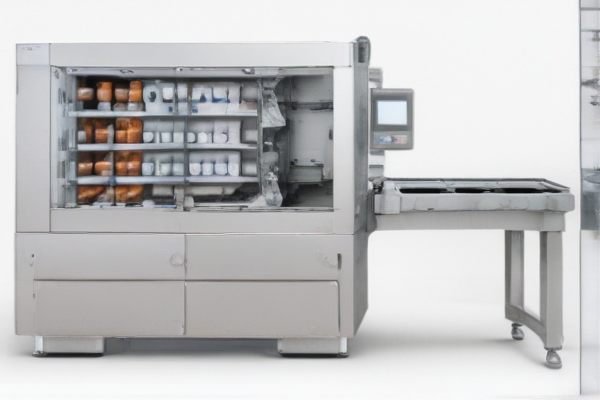

Q2: Can the machines handle various pill sizes and shapes?

A2: Yes, our pill packing machines are designed to accommodate a wide range of pill sizes and shapes. They are highly customizable to meet specific requirements.

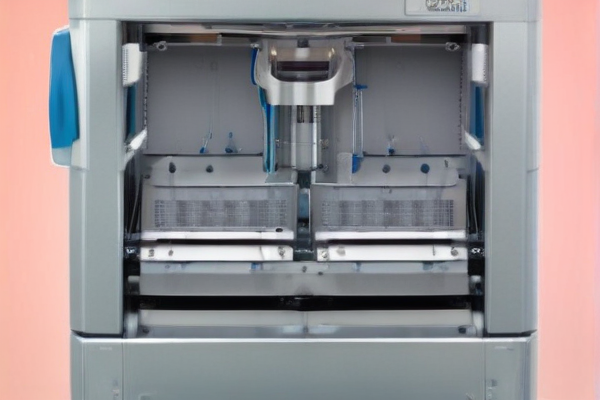

Q3: Are the machines easy to operate and maintain?

A3: Absolutely. The machines come with user-friendly interfaces and comprehensive manuals. Routine maintenance is straightforward, and our customer support is available to assist if needed.

Q4: What kind of quality control measures are in place?

A4: Each machine undergoes a rigorous quality control process, including multiple testing phases for functionality, safety, and efficiency before shipping.

Q5: How long is the warranty period for these machines?

A5: SourcifyChina offers a standard one-year warranty on all pill packing machines, covering parts and labor. Extended warranties are also available.

Q6: Do you offer training for operating the machines?

A6: Yes, we provide comprehensive training for your staff, either on-site or via detailed video tutorials, ensuring smooth operation from day one.

Q7: What is the average lead time for a custom order?

A7: The average lead time for a custom pill packing machine is approximately 6-8 weeks, depending on specific customization requirements.

Q8: How energy-efficient are the machines?

A8: Our pill packing machines are designed with energy efficiency in mind, utilizing the latest technology to minimize power consumption while maintaining high performance.

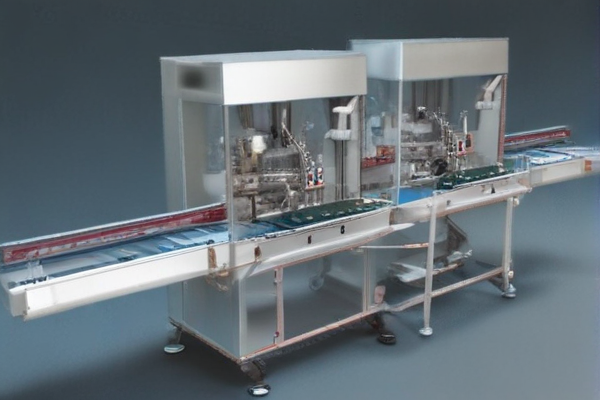

Q9: Can the machines integrate with existing production lines?

A9: Yes, our machines are designed for easy integration with current production lines, enhancing workflow efficiency and productivity.

Q10: What is the capacity of the pill packing machines?

A10: The capacity varies by model, but our machines can handle from 500 to 10,000 pills per minute, catering to both small and large-scale manufacturing needs.

These FAQs should give a comprehensive overview of the manufacturing and quality aspects of pill packing machines from SourcifyChina factory.