Sure, here are some frequently asked questions (FAQ) with answers, focused on the quality of work related to manufacturing plastic bag machines by the SourcifyChina factory:

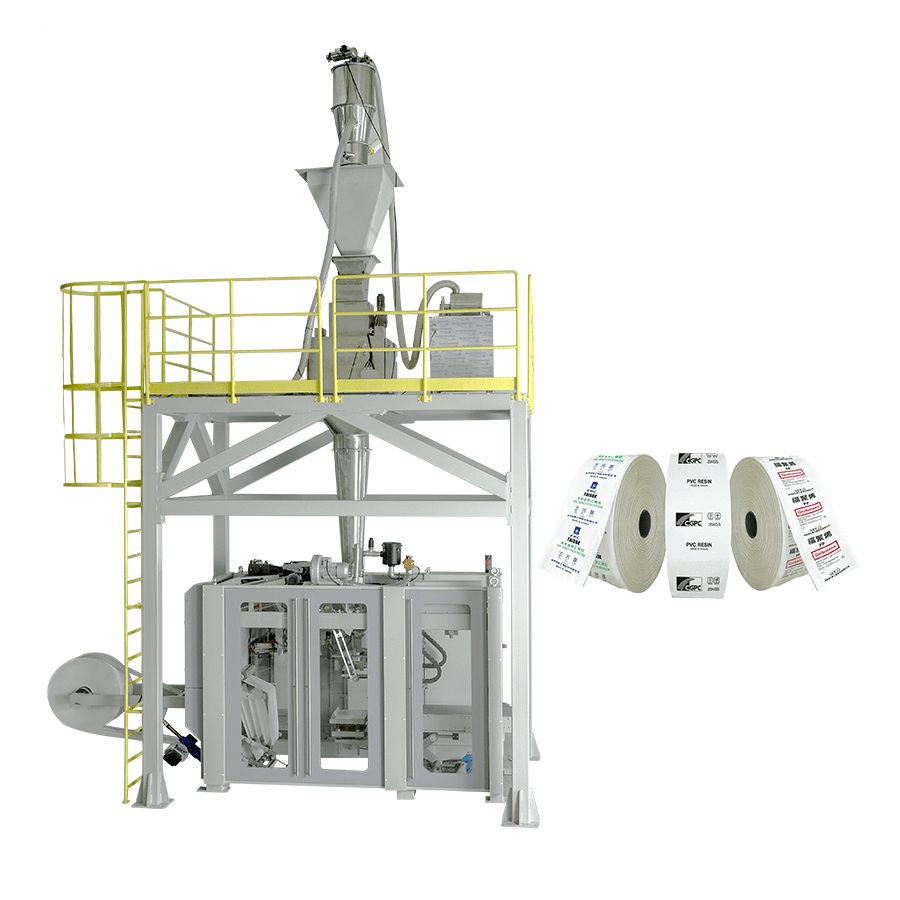

Q: What materials are used in manufacturing the plastic bag machines at SourcifyChina factory?

A: SourcifyChina factory uses high-grade steel and advanced alloy components to ensure durability and high performance in their plastic bag machines.

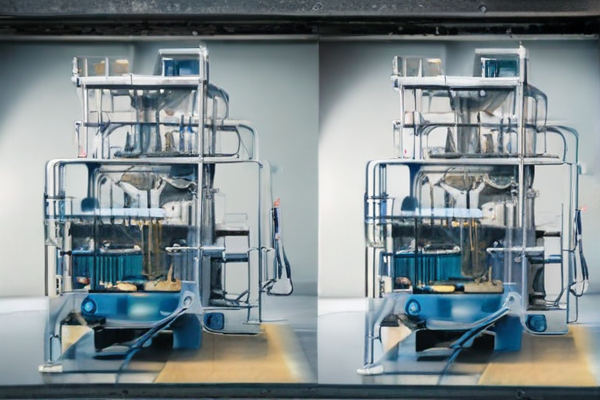

Q: How does SourcifyChina ensure quality control in their manufacturing process?

A: The factory employs a stringent quality control process, including multiple inspection points throughout the production line, ensuring each machine meets international standards.

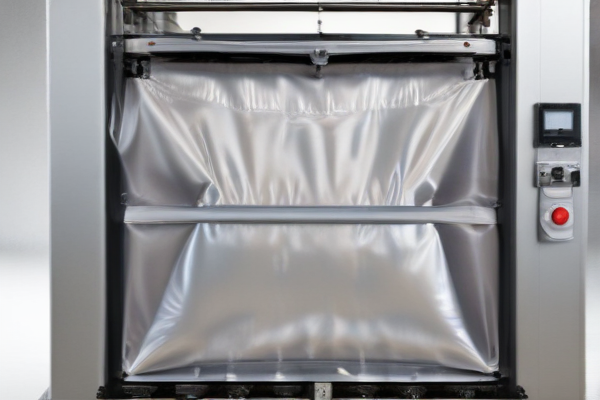

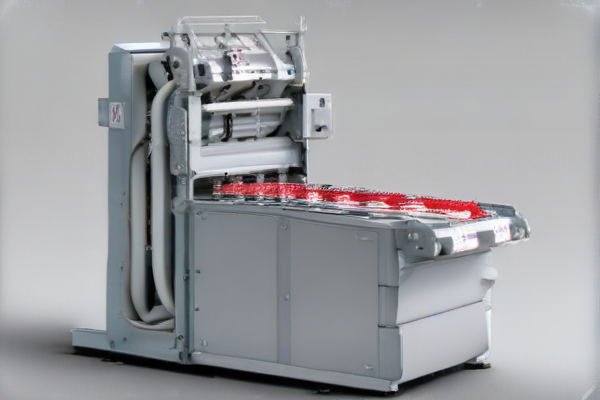

Q: Are the machines from SourcifyChina compatible with different types of plastics?

A: Yes, SourcifyChina’s plastic bag machines are designed to be versatile and can handle various types of plastics such as LDPE, HDPE, and biodegradable materials.

Q: Is there any warranty provided on machines from SourcifyChina?

A: SourcifyChina provides a standard one-year warranty on all its plastic bag machines, covering any manufacturing defects.

Q: What after-sales support does SourcifyChina offer?

A: SourcifyChina provides comprehensive after-sales support including installation guidance, troubleshooting, and access to spare parts.

Q: How does SourcifyChina ensure the energy efficiency of their machines?

A: The factory employs the latest technology to optimize energy consumption, reducing operational costs and environmental impact.

Q: Can SourcifyChina customize plastic bag machines according to specific requirements?

A: Yes, SourcifyChina offers customization options to meet unique business needs and specifications.

Q: What safety features are included in SourcifyChina’s plastic bag machines?

A: The machines are equipped with modern safety features such as emergency stop buttons, protective guards, and automated shut-off systems to ensure operator safety.

Q: How long does it typically take for SourcifyChina to deliver a plastic bag machine?

A: The lead time depends on the complexity and quantity of the order, but standard machines usually take 4-6 weeks for delivery.

Q: Are there any installation and training services provided by SourcifyChina?

A: Yes, SourcifyChina offers installation services and in-depth training sessions to ensure proper operation and maintenance of the machines.