FAQ for Manufacturing Post-Printing Machines Quality Work from SourcifyChina Factory

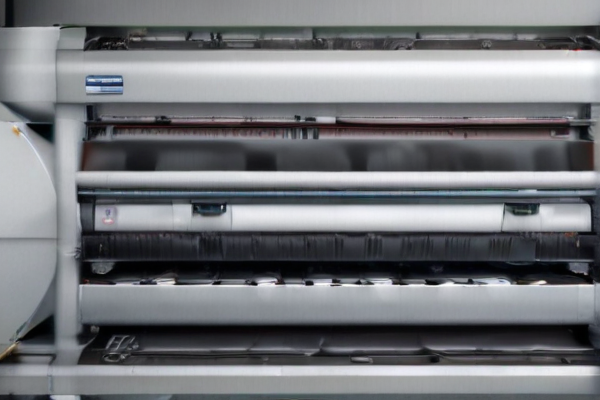

1. What types of post-printing machines does SourcifyChina manufacture?

SourcifyChina specializes in manufacturing various post-printing machines including laminators, die-cutters, varnishers, folding machines, and binding equipment designed for high-quality finishing.

2. How does SourcifyChina ensure the quality of their post-printing machines?

SourcifyChina follows stringent quality control measures, including rigorous testing and inspection processes throughout the manufacturing stages. The factory is ISO-certified, ensuring adherence to international standards.

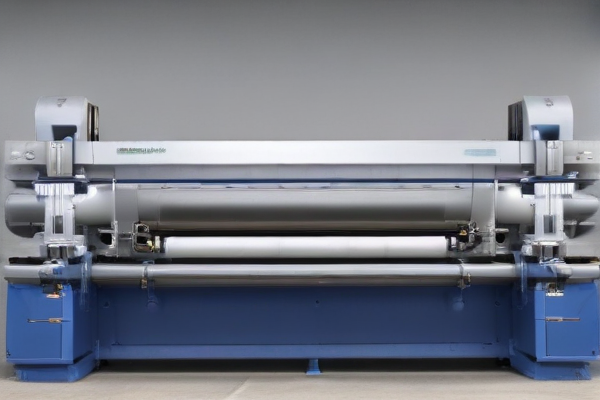

3. What materials are used in the construction of these machines?

High-grade materials such as stainless steel, aluminum alloys, and industrial-grade plastics are used to ensure durability, efficiency, and long service life of the machinery.

4. Can the machines be customized to specific requirements?

Yes, SourcifyChina offers customization services to cater to the specific needs of clients, including machine size, functional capabilities, and additional features.

5. What is the typical lead time for an order?

The lead time for an order varies depending on the scale and complexity of the customization. Generally, it ranges from 4 to 8 weeks from order confirmation to shipment.

6. Are there any warranties or after-sales services provided?

Yes, SourcifyChina provides a comprehensive warranty for all its machines, along with an after-sales service that includes maintenance support, spare parts availability, and technical assistance.

7. How can I place an order with SourcifyChina?

To place an order, you can contact SourcifyChina’s sales team through their website, email, or phone. Detailed specifications and requirements can be discussed to finalize the order.

8. Does SourcifyChina offer training for using their machines?

Yes, SourcifyChina provides training for staff to ensure proper operation and maintenance of the machines, which can be conducted either on-site or through virtual sessions.

9. What is the price range for SourcifyChina’s post-printing machines?

Pricing varies based on machine type, customization extent, and order volume. Contacting the sales team for a detailed quotation is recommended.

10. Are there any shipping options available for international clients?

SourcifyChina offers multiple shipping options for international clients, including air and sea freight, ensuring safe and timely delivery worldwide.