Here are some Frequently Asked Questions (FAQ) along with answers regarding the manufacturing of pouch filling equipment at SourcifyChina factory:

Q1: What types of pouch filling equipment does SourcifyChina manufacture?

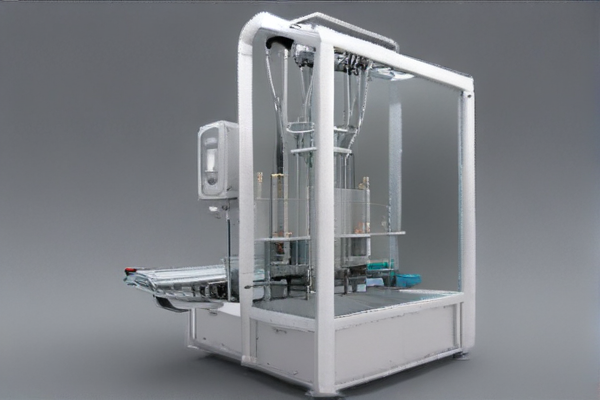

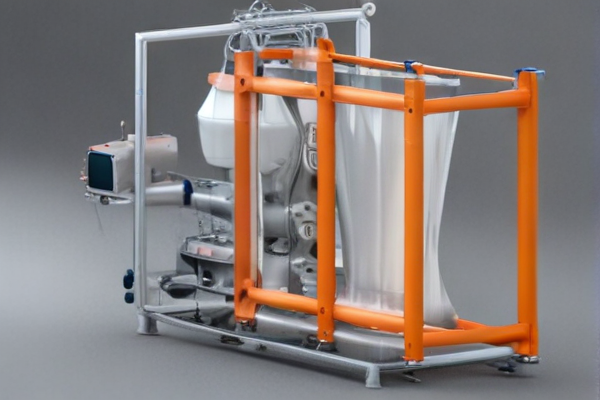

A1: SourcifyChina manufactures a wide variety of pouch filling equipment, including vertical form-fill-seal machines, pre-made pouch filling machines, and horizontal form-fill-seal machines. Each type can handle different pouch styles and sizes to accommodate various product needs.

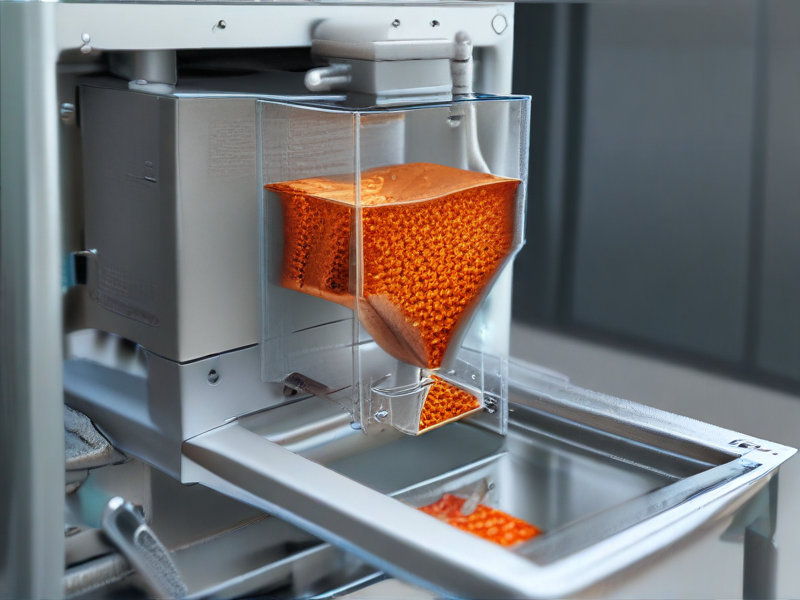

Q2: What materials can the pouch filling equipment from SourcifyChina handle?

A2: Our pouch filling machines are designed to handle a wide range of materials, including powders, granules, liquids, gels, and semi-solids. They can also package products into multiple types of pouches, such as stand-up pouches, flat pouches, and gusseted pouches.

Q3: How does SourcifyChina ensure the quality of its pouch filling equipment?

A3: At SourcifyChina, quality is a top priority. We utilize high-grade materials and advanced manufacturing techniques. Our equipment undergoes rigorous testing and quality control measures to ensure it meets international standards and customer specifications.

Q4: What customization options are available for pouch filling equipment?

A4: SourcifyChina offers extensive customization options, including adjustments in pouch size, filling speed, sealing methods, and integration with other equipment like conveyors and labeling machines. We work closely with clients to meet their specific requirements.

Q5: How long does it take to manufacture and deliver the equipment?

A5: The manufacturing and delivery time varies depending on the complexity and customization of the equipment. Typically, it takes around 8-12 weeks from the order confirmation to delivery. We strive to meet deadlines and maintain transparent communication throughout the process.

Q6: What kind of after-sales support does SourcifyChina provide?

A6: SourcifyChina offers comprehensive after-sales support, including installation assistance, operator training, and ongoing technical support. We also provide maintenance services and spare parts to ensure the longevity and efficiency of your equipment.

Q7: Are the machines energy-efficient?

A7: Yes, SourcifyChina designs its pouch filling equipment with energy efficiency in mind. Our machines are built to operate efficiently with minimal energy consumption, contributing to lower operational costs and environmental impact.

Q8: Can I get a demonstration or trial run before purchase?