Certainly! Here are some Frequently Asked Questions (FAQ) along with their answers for manufacturing “pouch filling machine quality work from SourcifyChina factory” under 300 words:

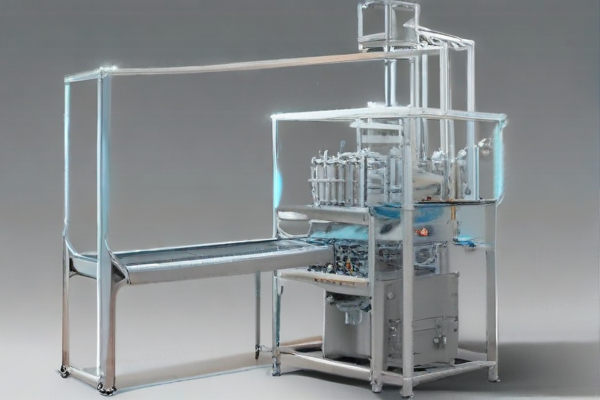

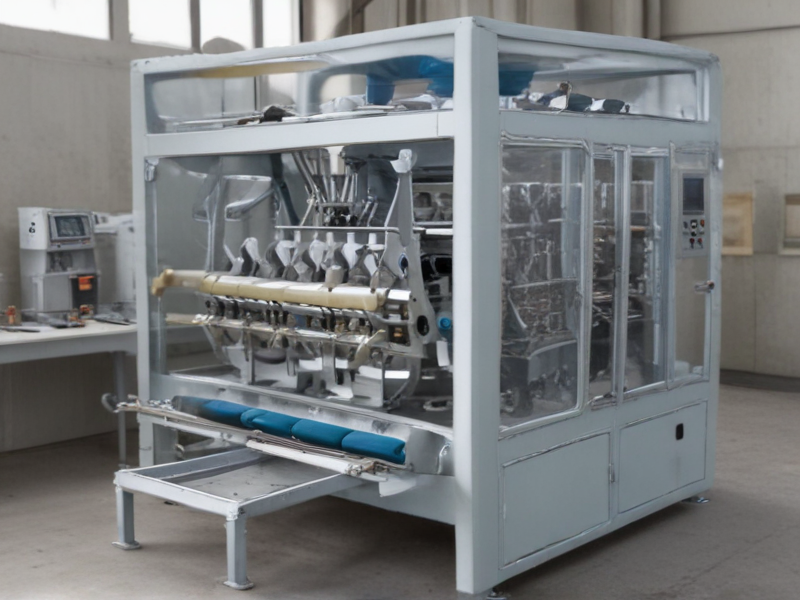

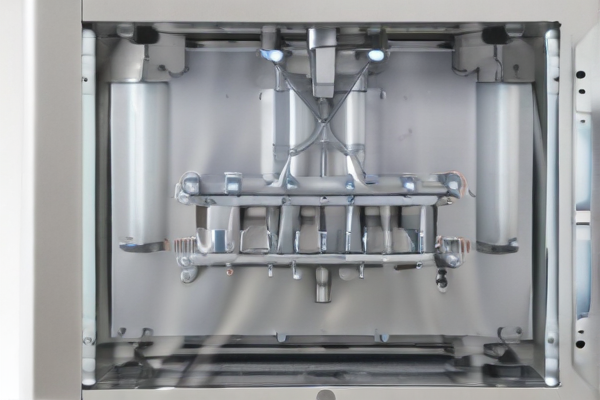

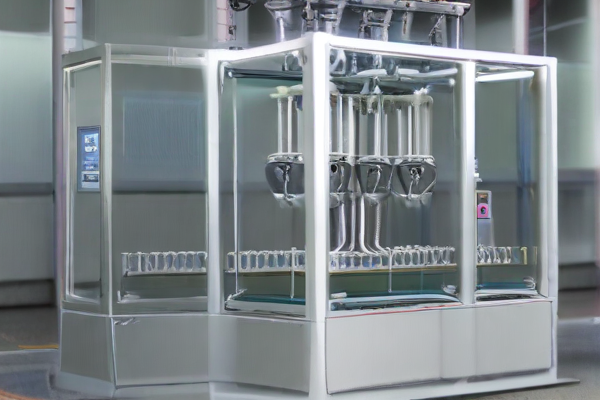

Q1: What types of pouch filling machines does SourcifyChina factory offer?

A1: SourcifyChina factory offers a wide range of pouch filling machines, including automatic, semi-automatic, rotary, and linear filling machines, suitable for different pouch formats and production capacities.

Q2: Are SourcifyChina’s pouch filling machines customizable?

A2: Yes, SourcifyChina provides customization options to tailor the machines according to specific requirements, such as pouch dimensions, filling volume, and material compatibility.

Q3: What quality assurance measures are in place at SourcifyChina?

A3: SourcifyChina adheres to strict quality control processes including ISO certification, rigorous testing, and routine inspections to ensure high-quality manufacturing standards.

Q4: How long does it take to manufacture and deliver a pouch filling machine?

A4: The manufacturing and delivery timeline typically ranges from 8 to 12 weeks, depending on the complexity and customization requirements of the order.

Q5: What after-sales support does SourcifyChina offer?

A5: SourcifyChina provides comprehensive after-sales support including installation guidance, training, technical support, and maintenance services to ensure your machine operates efficiently.

Q6: Can the machines handle different types of products?

A6: Yes, the machines are designed to handle a variety of products such as liquids, powders, pastes, and granules, accommodating diverse industry needs.

Q7: What packaging materials are compatible with SourcifyChina’s pouch filling machines?

A7: The machines are compatible with various packaging materials like polyethylene, laminates, and aluminum foils, offering flexibility in packaging options.

Q8: How energy-efficient are the pouch filling machines from SourcifyChina?

A8: SourcifyChina’s machines are designed to be energy-efficient, incorporating advanced technology to minimize power consumption and reduce operational costs.

Q9: Do the machines comply with international safety standards?

A9: Yes, all machines from SourcifyChina comply with international safety standards including CE and UL certifications, ensuring safe and reliable operation.

Q10: How can I get a quote for a pouch filling machine?