Here’s a concise FAQ for a manufacturing “pouch labeling machine quality work from SourcifyChina factory” under 300 words, with questions in bold:

Q1: What types of pouches can the labeling machine handle?

The machine can handle various types of pouches including stand-up pouches, flat pouches, gusseted pouches, and more. It’s designed for versatility to accommodate different packaging needs.

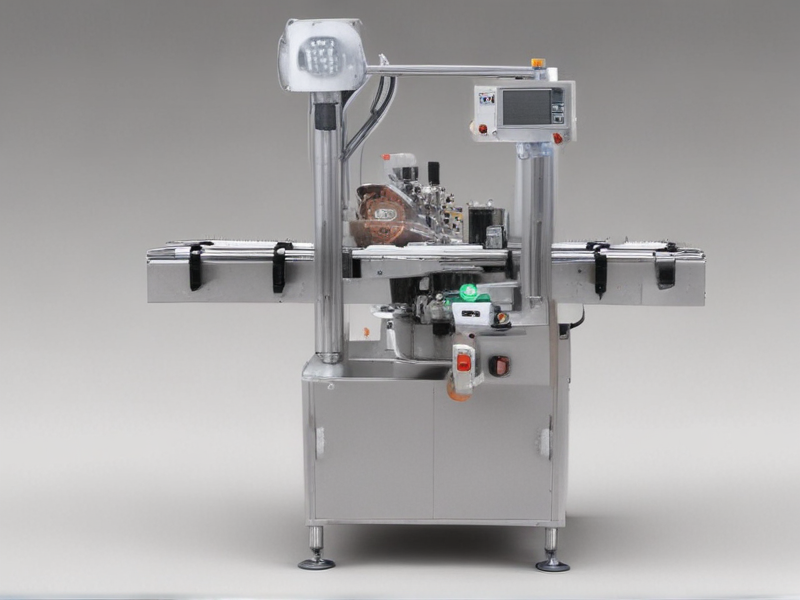

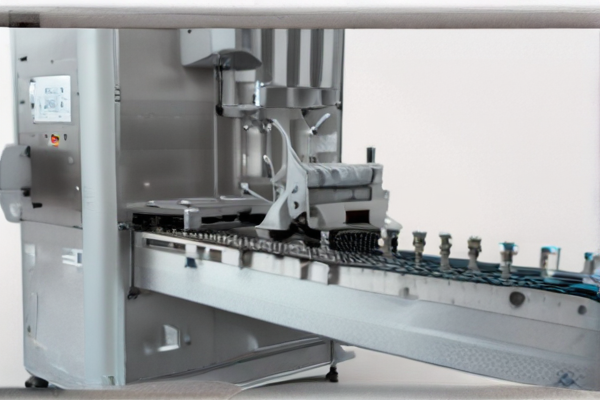

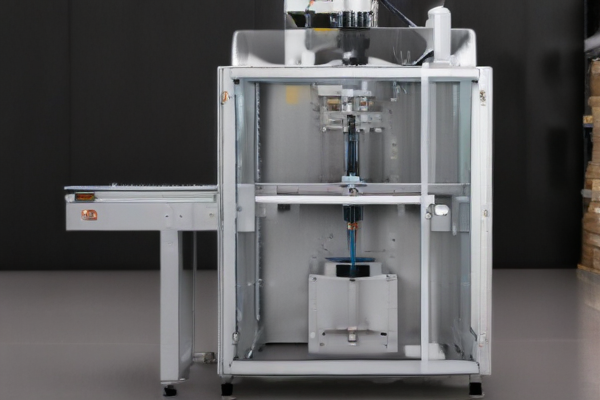

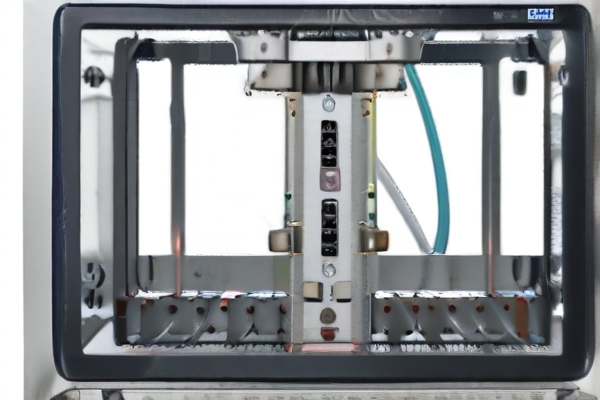

Q2: What are the key features of the pouch labeling machine?

Key features include high-speed labeling, precision alignment, adjustable settings for different pouch sizes, and compatibility with various label materials. It also incorporates user-friendly controls and a robust build for durability.

Q3: What materials are used in the construction of the machine?

The machine is constructed using high-quality stainless steel and aluminum alloys, ensuring durability and resistance to corrosion. All materials meet industrial standards.

Q4: Is the machine easy to operate and maintain?

Yes, the machine is designed for ease of operation with a straightforward interface. Maintenance is minimal, and the machine includes accessible components for easy cleaning and servicing.

Q5: Can the machine be customized?

Yes, SourcifyChina offers customization options to meet specific requirements, including adjustments for unique pouch sizes, shapes, and labeling positions.

Q6: What is the average lead time for manufacturing and delivery?

The average lead time ranges from 4-6 weeks, depending on customization and order volume. Delivery times may vary based on your location.

Q7: Does the machine come with a warranty?

Yes, the machine comes with a standard one-year warranty, covering parts and labor. Extended warranties are available upon request.

Q8: Are there any training and support services?

SourcifyChina provides comprehensive training for your staff, along with ongoing technical support to ensure optimal performance and address any issues.

Q9: How does SourcifyChina ensure quality control?

Our factory follows stringent quality control protocols, including multiple testing stages, to ensure each machine meets industry standards and customer specifications.

Q10: What are the power requirements for the machine?

The machine typically requires a standard voltage of 220V/50Hz. However, power specifications can be adjusted based on your region’s requirements.