Sure, here are some frequently asked questions (FAQ) and answers regarding the manufacturing of quality pouch machines by SourcifyChina factory:

1. What types of pouch machines does SourcifyChina manufacture?

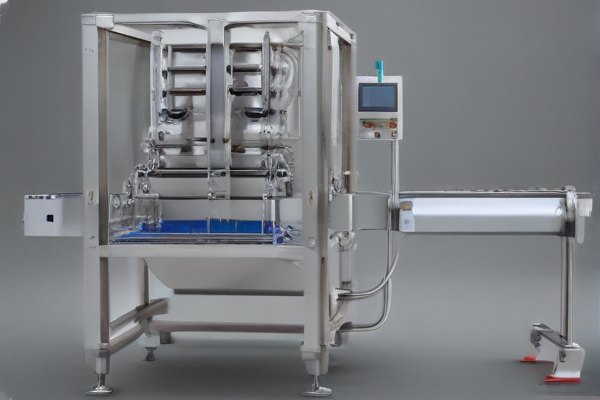

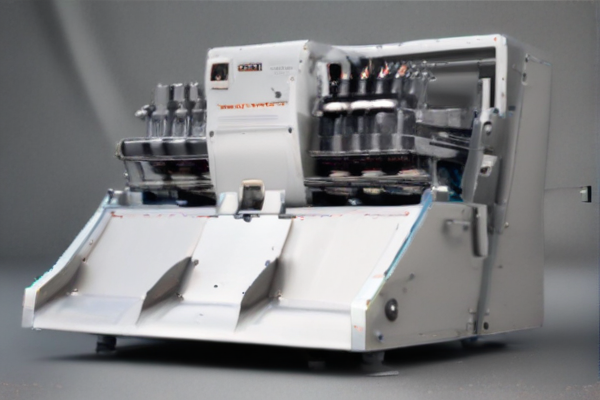

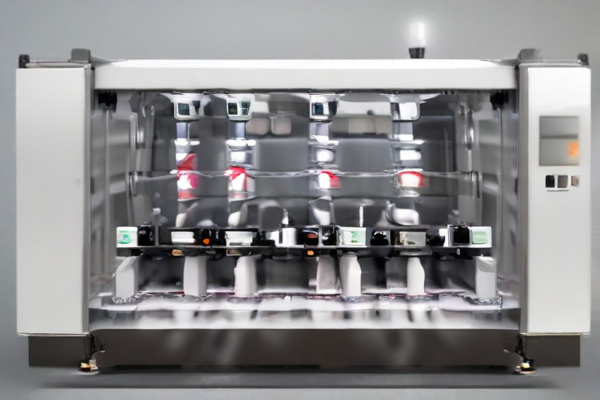

SourcifyChina manufactures a range of pouch machines including stand-up pouch machines, zipper pouch machines, spout pouch machines, flat pouch machines, and specialty pouch machines customized to client specifications.

2. Are the machines customizable according to specific requirements?

Yes, SourcifyChina offers customization options. Clients can specify dimensions, operational features, and specific functionalities required for their pouch machines.

3. What materials are compatible with SourcifyChina’s pouch machines?

SourcifyChina’s machines are designed to handle a variety of materials including but not limited to plastic films, laminates, paper, and aluminum foil.

4. How does SourcifyChina ensure the quality of its pouch machines?

Quality assurance is ensured through rigorous testing and quality control processes at various stages of production. SourcifyChina adheres to international standards such as ISO and CE certifications.

5. What is the average lead time for manufacturing and delivering a pouch machine?

The average lead time ranges from 4 to 8 weeks, depending on the complexity and customization requirements of the order.

6. Can SourcifyChina provide training and support for operating the pouch machines?

Yes, SourcifyChina offers comprehensive training and support packages, including on-site training, user manuals, and 24/7 customer service for technical support.

7. What is the warranty period for SourcifyChina’s pouch machines?

Most pouch machines come with a standard one-year warranty covering parts and labor. Extended warranty options are also available.

8. How does SourcifyChina handle maintenance and repair services?

SourcifyChina provides both preventive maintenance plans and repair services. Technicians can be dispatched globally, and spare parts are readily available.

9. Are there financing options available for purchasing pouch machines?

Yes, SourcifyChina offers various financing arrangements to suit the financial needs of different clients. These options can be discussed with the sales team.

10. How can I get a quote or place an order for a pouch machine?

To get a quote or place an order, you can contact the SourcifyChina sales team via their website, email, or phone. Providing detailed requirements will help in preparing an accurate quote.