Sure, here is a FAQ list regarding the quality and work of pouch packaging machines manufactured by SourcifyChina Factory:

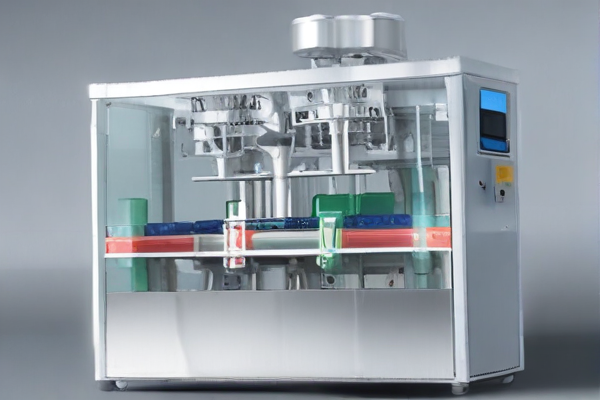

Q: What types of pouch packaging machines does SourcifyChina factory manufacture?

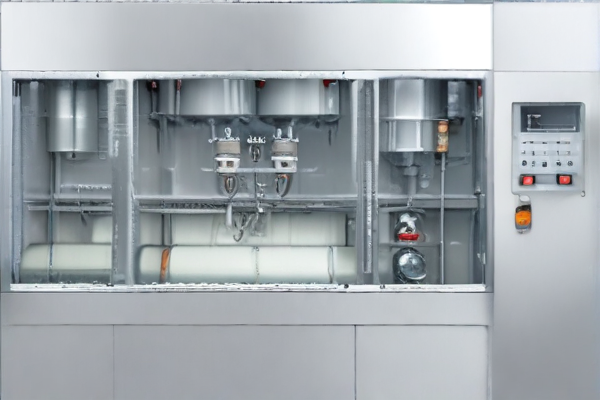

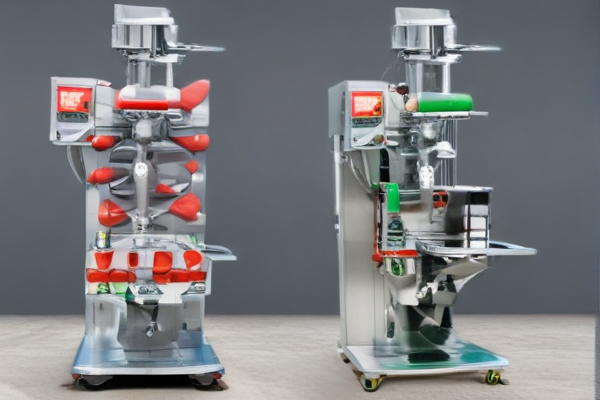

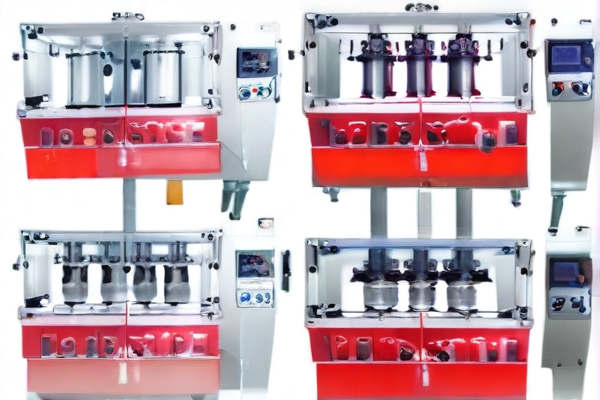

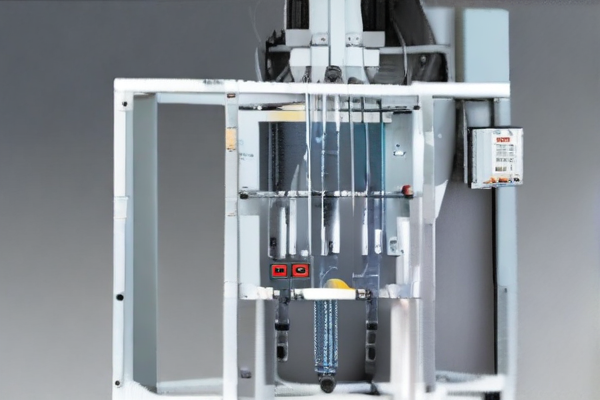

A: SourcifyChina factory manufactures various types of pouch packaging machines, including vertical form fill seal (VFFS) machines, horizontal form fill seal (HFFS) machines, stand-up pouch machines, and flat pouch machines.

Q: Are the pouch packaging machines from SourcifyChina factory customizable?

A: Yes, SourcifyChina factory offers customization options to meet the specific needs of different clients. Customizations can include machine size, capacity, and functionality to suit various packaging requirements.

Q: What is the quality control process for pouch packaging machines at SourcifyChina factory?

A: SourcifyChina factory employs a rigorous quality control process that includes multiple stages of testing and inspection. Each machine undergoes performance testing, durability testing, and accuracy checks to ensure it meets industry standards and client specifications.

Q: How long does it typically take to manufacture a pouch packaging machine?

A: The manufacturing time for a pouch packaging machine can vary depending on the complexity and customization required. On average, it takes about 4-8 weeks from order confirmation to delivery.

Q: Does SourcifyChina factory provide installation and training services?

A: Yes, SourcifyChina factory offers installation and training services. Their technical team can assist with on-site installation and provide comprehensive training to ensure efficient and effective operation of the machines.

Q: What after-sales support does SourcifyChina factory offer?

A: SourcifyChina factory provides robust after-sales support, including a warranty period, spare parts supply, and technical assistance. They offer 24/7 customer service to address any issues or concerns promptly.

Q: Are SourcifyChina’s pouch packaging machines energy efficient?

A: Yes, SourcifyChina’s pouch packaging machines are designed with energy efficiency in mind. They incorporate advanced technology to minimize power consumption while maintaining high performance and productivity.

Q: Can SourcifyChina factory’s pouch packaging machines handle different packaging materials?

A: Absolutely. SourcifyChina’s machines are versatile and can handle a wide range of packaging materials, including plastic films, laminates, and foil-based materials.

Q: Is it possible to see a demonstration of the pouch packaging machines before purchasing?