Sure, here is a concise list of FAQs with answers for sourcing a powder dispenser machine from SourcifyChina factory:

1. What types of powder dispenser machines does SourcifyChina offer?

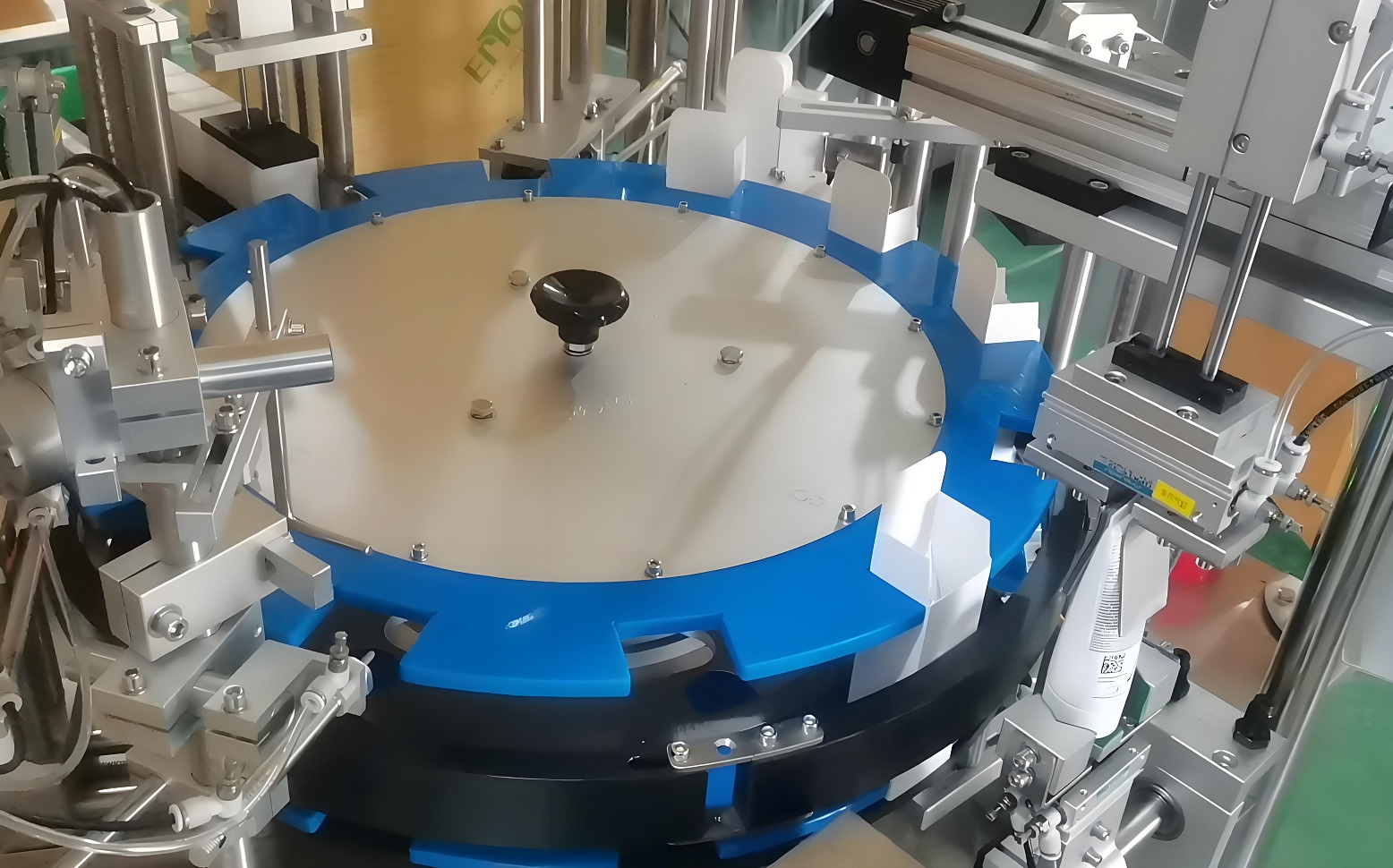

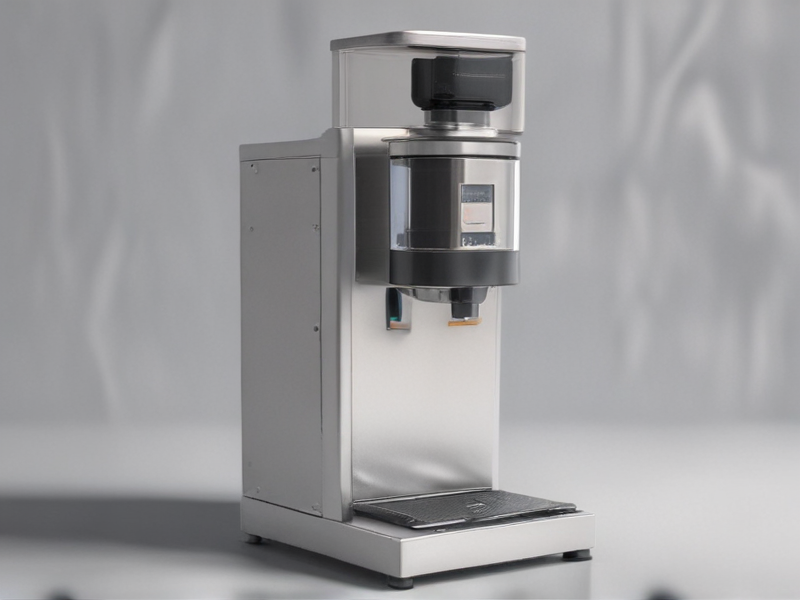

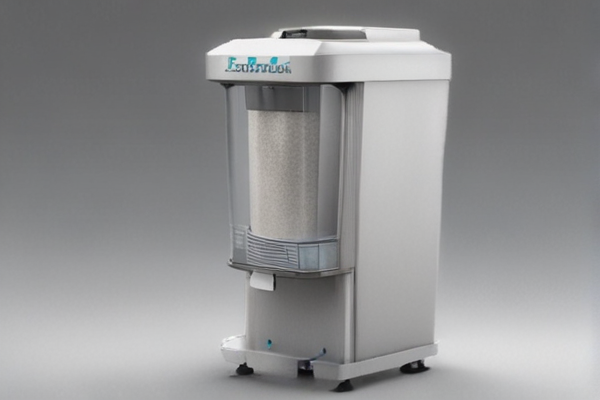

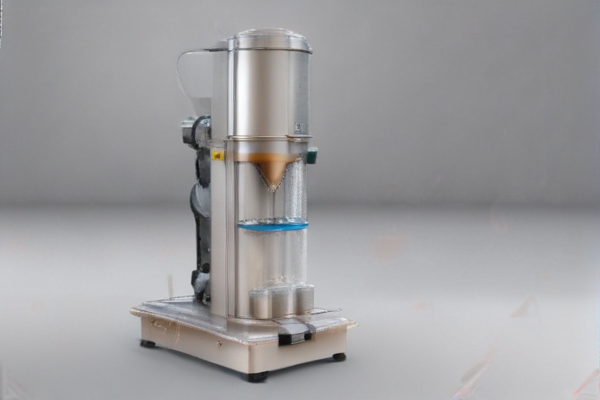

SourcifyChina offers a variety of powder dispenser machines, including automatic, semi-automatic, and manual models suitable for different industries like food, pharmaceuticals, and cosmetics.

2. What materials are these machines made from?

The powder dispenser machines are made from high-quality stainless steel, ensuring durability and compliance with hygiene standards.

3. Can these machines be customized?

Yes, SourcifyChina provides customization options to meet specific requirements, including adjustments in size, capacity, and additional features.

4. What is the lead time for an order?

The lead time typically ranges from 4 to 6 weeks, depending on the machine model and customization needs.

5. What are the payment terms?

Common payment terms are a 30% deposit upon order confirmation and the remaining 70% before shipment. SourcifyChina accepts payments via bank transfer, credit card, and other secure payment methods.

6. Is there a warranty for the powder dispenser machines?

Yes, SourcifyChina offers a one-year warranty on all powder dispenser machines covering any manufacturing defects.

7. Do they provide after-sales service?

Yes, SourcifyChina offers comprehensive after-sales support, including troubleshooting, maintenance guidance, and spare parts supply.

8. Can I request a sample before placing a bulk order?

Yes, samples can be provided for a fee, which is often deducted from the total cost if a bulk order follows.

9. What kind of certifications do the machines have?

The machines are ISO, CE, and FDA certified, ensuring that they meet international safety and quality standards.

10. How can I get a quote?

You can obtain a quote by contacting SourcifyChina directly through their website, email, or via their sales representatives. Provide details of your requirements for an accurate estimate.