Certainly! Here are some frequently asked questions (FAQ) regarding sourcing powder filling equipment from SourcifyChina factory, along with their answers:

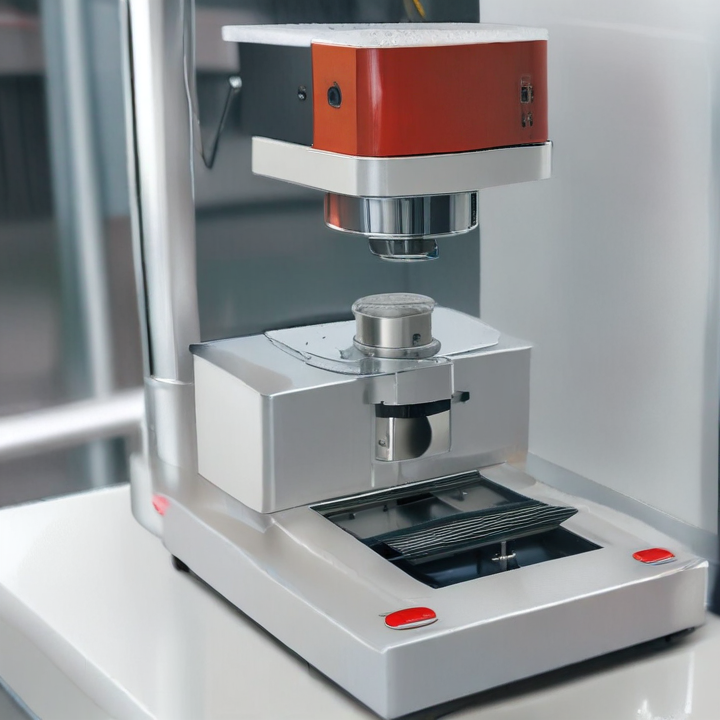

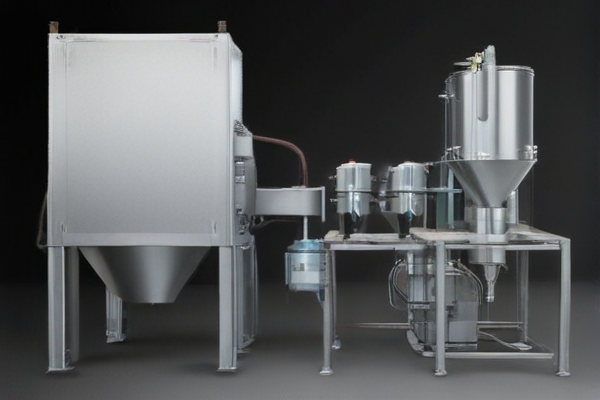

Q1: What types of powder filling equipment does SourcifyChina factory provide?

A1: SourcifyChina factory offers a wide range of powder filling equipment, including semi-automatic and fully automatic powder filling machines, auger fillers, and volumetric fillers. They cater to various industries such as pharmaceuticals, food, and chemicals.

Q2: What is the lead time for order fulfillment?

A2: The lead time for order fulfillment typically ranges from 4 to 8 weeks, depending on the specific requirements and customization needed for the equipment. It’s advisable to confirm the exact timeline with their sales team.

Q3: Do they offer customization services?

A3: Yes, SourcifyChina factory offers customization services to meet specific needs such as machine size, filling speed, and type of powder. Clients can discuss their unique requirements with the technical team to ensure a tailored solution.

Q4: What quality standards do the machines comply with?

A4: The powder filling equipment from SourcifyChina is manufactured in compliance with international quality standards such as ISO, CE, and GMP. This ensures high performance, reliability, and safety.

Q5: Is there any warranty or after-sales service?

A5: SourcifyChina factory provides a standard one-year warranty on all powder filling equipment. They also offer comprehensive after-sales service, including installation support, training, and maintenance.

Q6: How can I request a quote or place an order?

A6: To request a quote or place an order, you can visit SourcifyChina factory’s official website and fill out the inquiry form. Alternatively, you can contact their sales team directly via email or phone for assistance.

Q7: What payment methods are accepted?

A7: SourcifyChina factory accepts various payment methods, including T/T (Telegraphic Transfer), L/C (Letter of Credit), and Western Union. Specific payment terms can be discussed with their sales representatives.

Q8: Do they provide technical support and training?

A8: Yes, SourcifyChina factory offers technical support and training to ensure that your team can efficiently operate and maintain the equipment. This can include on-site installation and training sessions.

This FAQ should give you a good overview of the process and services related to sourcing powder filling equipment from SourcifyChina factory.