Sure, here are some FAQs regarding manufacturing quality powder filling machines from SourcifyChina factory:

1. What types of powder filling machines does SourcifyChina manufacture?

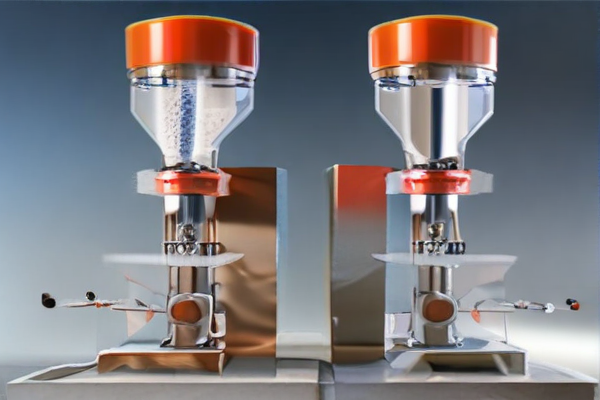

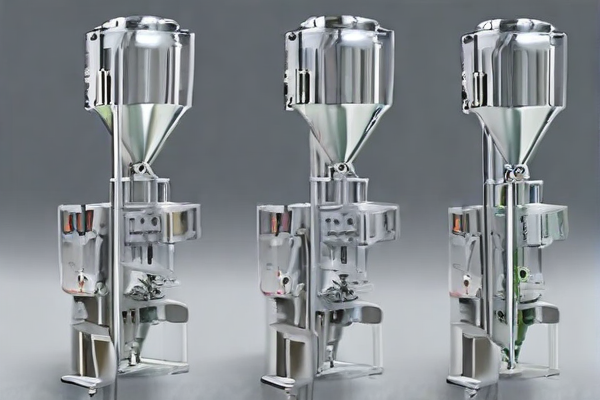

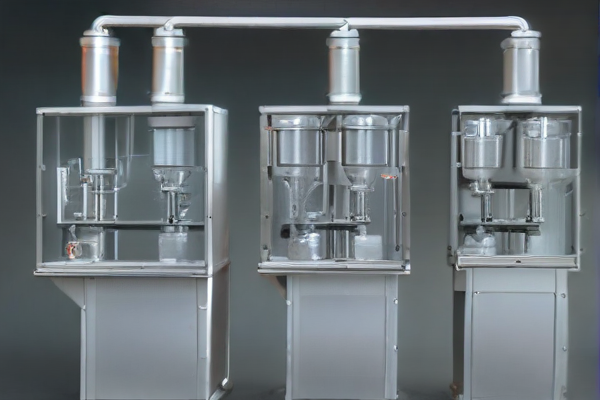

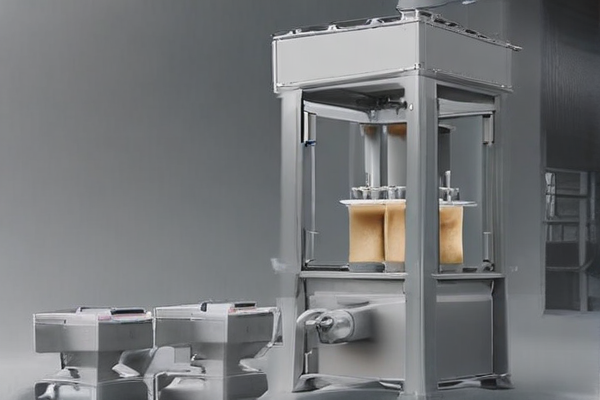

SourcifyChina manufactures a wide range of powder filling machines, including auger fillers, volumetric fillers, semi-automatic and fully automatic filling machines designed for various powder types such as pharmaceuticals, food, chemicals, and cosmetics.

2. What materials are used in SourcifyChina’s powder filling machines?

The machines are primarily made from high-quality stainless steel to ensure durability, sanitary conditions, and compliance with international manufacturing standards.

3. How does SourcifyChina ensure the quality of its powder filling machines?

SourcifyChina employs rigorous quality control processes that include comprehensive inspections, performance testing, and validation according to ISO and CE standards. Each machine undergoes trial runs before delivery to ensure optimal performance.

4. Are custom machine designs available at SourcifyChina?

Yes, SourcifyChina offers customization options to meet specific client needs, including machine size, speed, and additional features like automatic capping or labeling systems.

5. What kind of support and training does SourcifyChina provide?

SourcifyChina provides thorough user manuals, on-site training for operating and maintenance, and remote technical support to ensure smooth operations.

6. Can SourcifyChina handle large volume orders?

Yes, SourcifyChina has the production capacity to handle large volume orders while maintaining high quality and timely delivery.

7. What is the usual lead time for manufacturing and delivery?

The standard lead time typically ranges from 4 to 8 weeks, depending on the machine’s complexity and customization requirements.

8. Is there a warranty on the powder filling machines?

SourcifyChina offers a standard one-year warranty covering parts and labor. Extended warranty options are also available upon request.

9. How can I place an order with SourcifyChina?

Orders can be placed directly through email inquiries, their official website, or via authorized distributors. Initial consultations to discuss requirements can be scheduled easily.

10. Does SourcifyChina offer after-sales services?

Yes, SourcifyChina provides comprehensive after-sales services including spare parts supply, machine upgrade solutions, and regular maintenance check-ups.

These FAQs should help you understand the offerings and quality assurance provided by SourcifyChina for their powder filling machines.