1. What types of powder packaging machines are available from SourcifyChina factory?

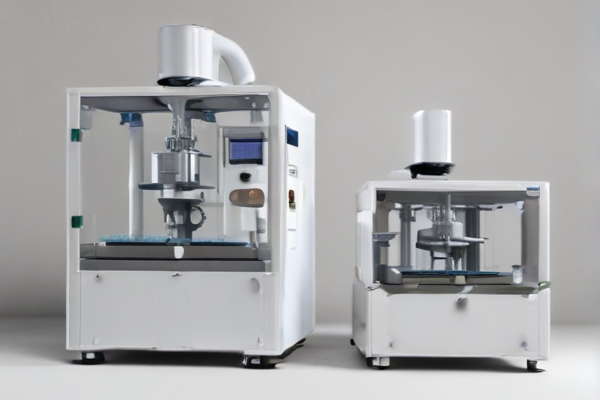

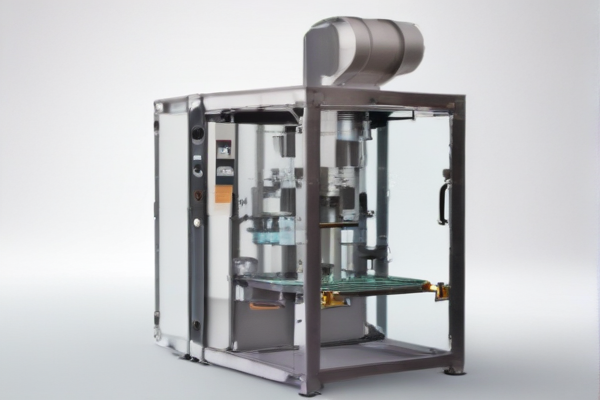

SourcifyChina factory offers a variety of powder packaging machines, including vertical form fill seal machines, auger filling machines, and stick pack machines, suitable for different powder types and packaging needs.

2. What are the key features of the powder packaging machines at SourcifyChina factory?

Key features include high-speed operation, precision dosing, user-friendly interfaces, robust construction, and customizable options to accommodate various powder types and packaging formats.

3. Can I get a customized powder packaging machine to meet my specific requirements?

Yes, SourcifyChina factory offers customization services. You can work with their engineers to design a machine tailored to your specific needs, including size, speed, and additional functionalities.

4. What is the lead time for a powder packaging machine order from SourcifyChina factory?

The lead time generally ranges from 4 to 8 weeks, depending on the complexity and customization level of the machine. It’s best to contact the factory directly for a precise timeline.

5. Do the machines come with a warranty?

Yes, all powder packaging machines from SourcifyChina factory come with a standard one-year warranty, covering parts and labor. Extended warranty options may also be available.

6. How do I install and set up the machine after purchase?

SourcifyChina provides detailed installation manuals and video tutorials. Additionally, you can opt for professional installation services by their technicians for comprehensive setup and training.

7. What after-sales services are provided by SourcifyChina factory?

They offer robust after-sales support, including remote troubleshooting, software updates, spare parts supply, and maintenance services to ensure optimal machine performance.

8. Can I request a demo or a visit to the factory before purchasing?

Yes, you can request a live demo or schedule a visit to the SourcifyChina factory to see the machines in action and discuss your requirements with their team.

9. What payment methods are accepted?

SourcifyChina factory accepts various payment methods, including bank transfers (T/T), credit cards, and letters of credit (L/C), ensuring a secure transaction process.

10. How can I place an order for a powder packaging machine?

You can place an order by contacting SourcifyChina factory directly through their website contact form, email, or phone. Their sales team will guide you through the process and assist with any queries.