Sure! Below is a list of frequently asked questions (FAQs) with answers for sourcing a pre-roll joint machine from SourcifyChina factory.

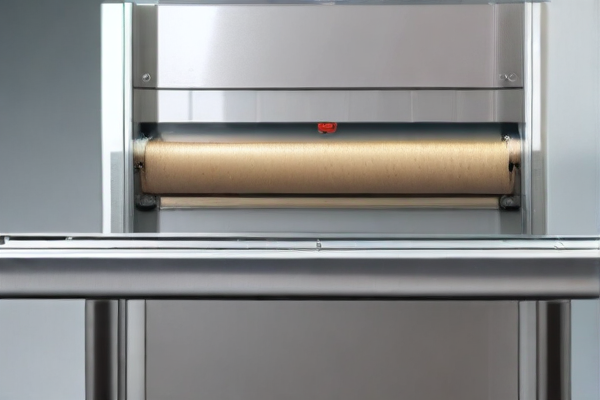

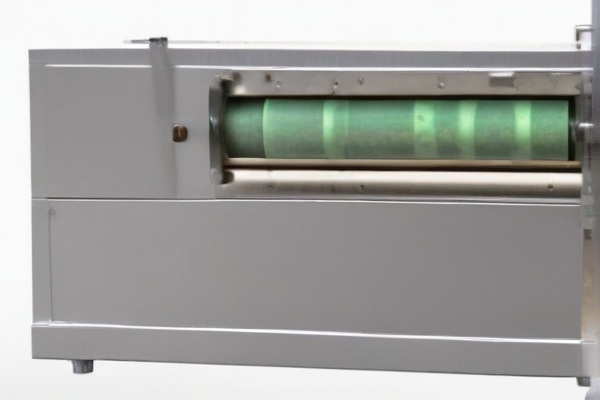

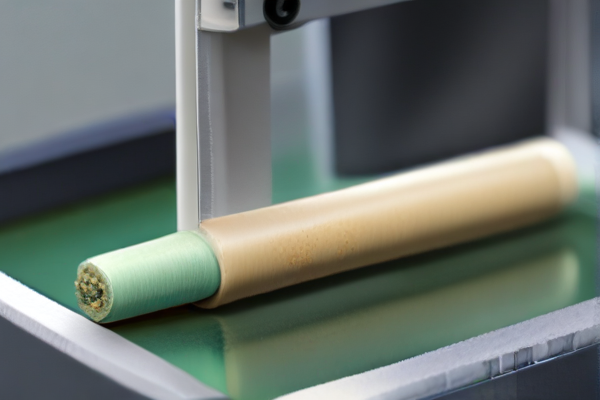

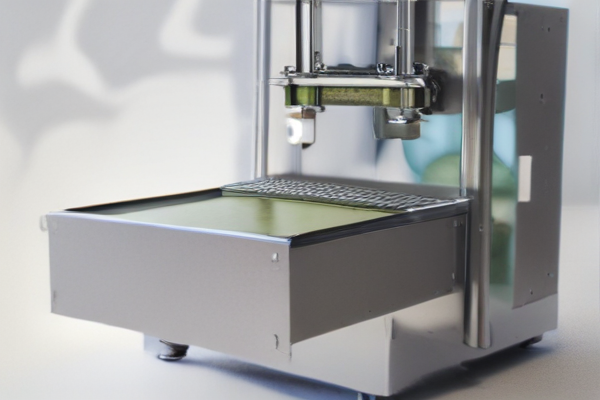

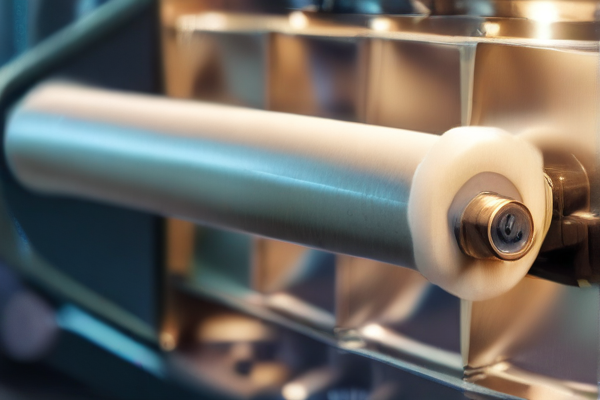

Q: What type of pre-roll joint machines are available at SourcifyChina factory?

A: SourcifyChina factory offers a variety of pre-roll joint machines, including manual, semi-automatic, and fully automatic models. These machines are designed to meet different production needs and budget constraints.

Q: How can I place an order for a pre-roll joint machine?

A: To place an order, you can visit the SourcifyChina website, fill out the inquiry form, or contact their sales team directly via email or phone. A sales representative will guide you through the process.

Q: What is the lead time for delivery after placing an order?

A: The lead time varies depending on the machine model and order quantity. Typically, the lead time ranges from 2 to 6 weeks. The exact timeframe will be confirmed once the order is placed.

Q: Do you offer customization options for the pre-roll joint machines?

A: Yes, SourcifyChina factory provides customization options to tailor the machines according to your specific requirements, including size, capacity, and additional features.

Q: What payment methods are accepted?

A: SourcifyChina factory accepts various payment methods, including wire transfer (T/T), PayPal, and Letter of Credit (L/C) for international orders.

Q: Are the machines covered under warranty?

A: Yes, all pre-roll joint machines come with a standard warranty period, which usually ranges from 1 to 2 years. The warranty covers manufacturing defects and faulty components.

Q: Can I get technical support and after-sales service?

A: Yes, SourcifyChina factory provides comprehensive technical support and after-sales service. You can reach out to their service team for assistance with installation, maintenance, and troubleshooting.

Q: What shipping options are available?

A: SourcifyChina factory offers multiple shipping options, including air freight, sea freight, and express courier services. Shipping costs and delivery times will be provided at the time of order confirmation.

Q: Is training provided for operating the pre-roll joint machine?

A: Yes, SourcifyChina factory offers training sessions to help your staff learn how to operate and maintain the pre-roll joint machines effectively.