What sets the pre-rolls machine from SourcifyChina factory apart in terms of quality?

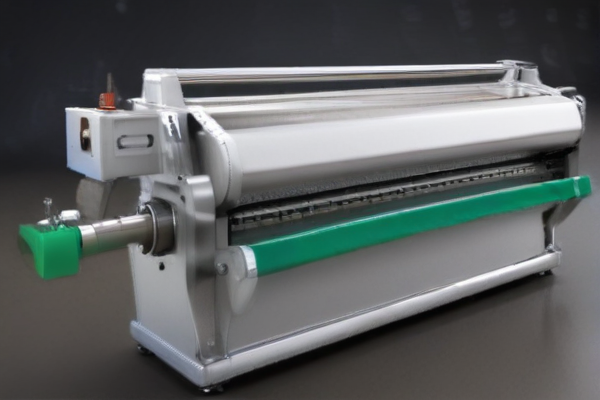

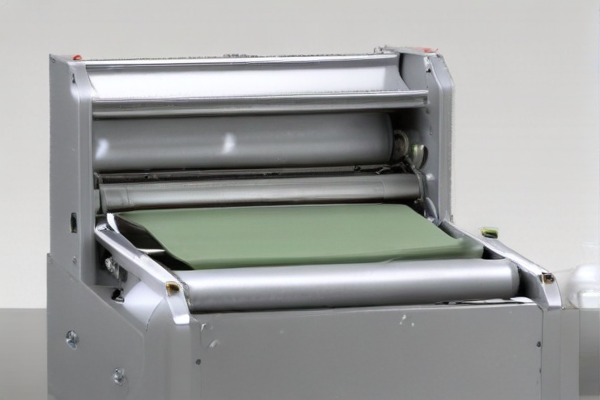

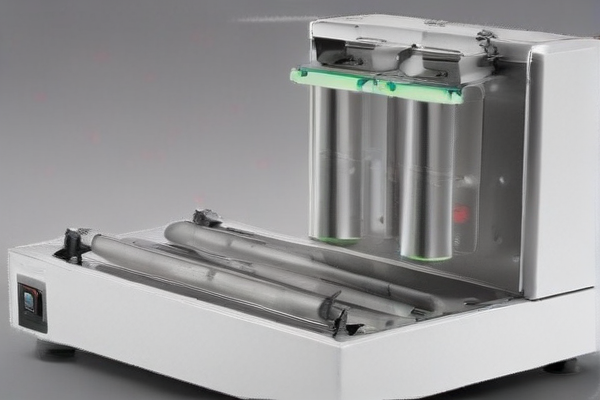

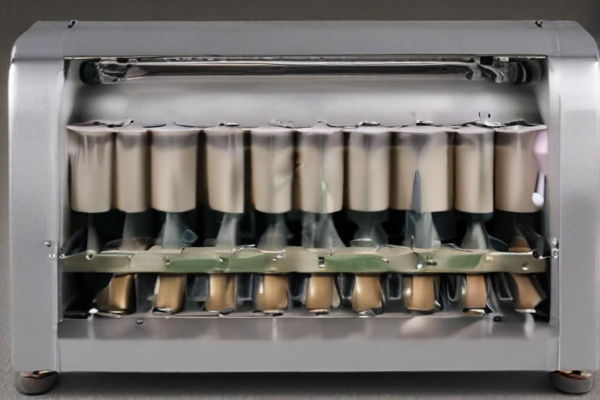

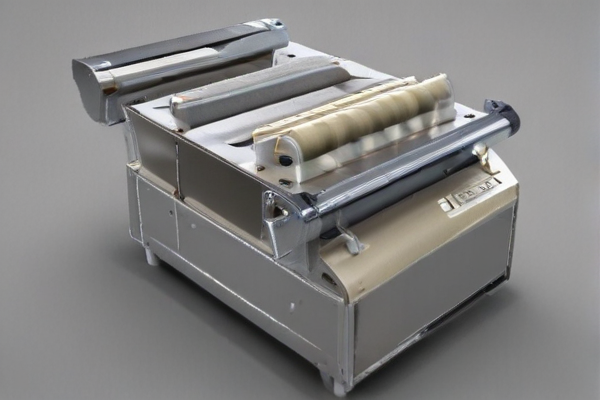

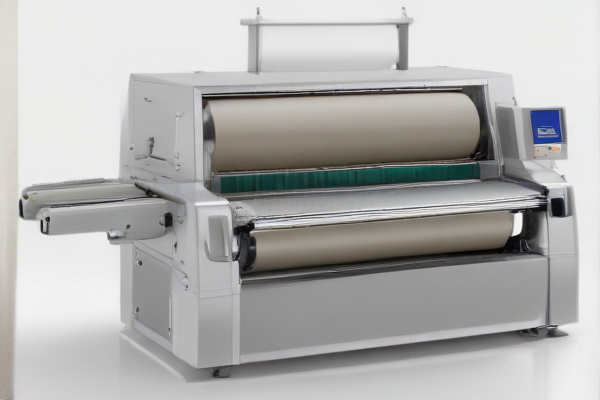

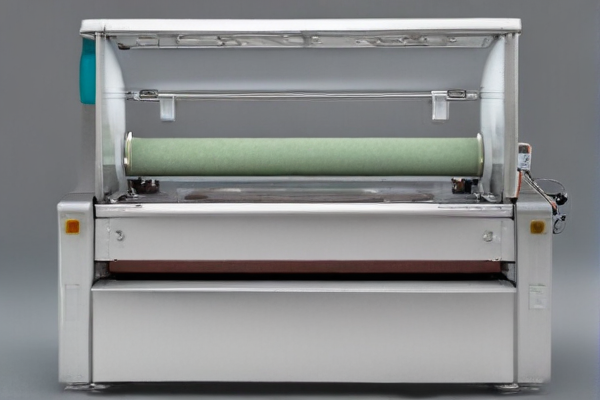

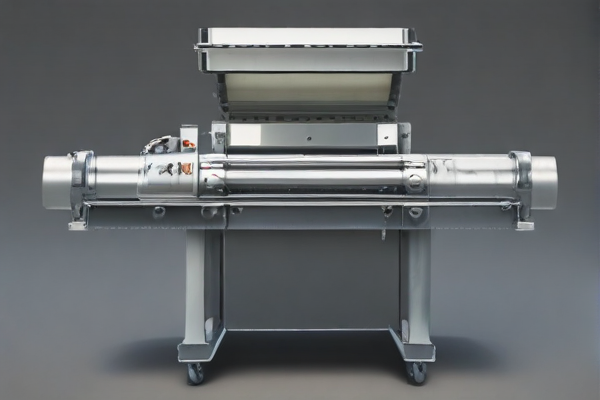

SourcifyChina factory’s pre-rolls machines are manufactured using high-grade materials and cutting-edge technology. The machines undergo rigorous quality control tests to ensure durability, precision, and consistent performance.

How does SourcifyChina ensure the quality of their pre-rolls machines?

SourcifyChina adheres to strict quality control protocols, including multiple stages of inspection, performance testing, and the use of ISO-certified processes to ensure the machines meet international standards.

What kind of maintenance is required for these pre-rolls machines?

Routine maintenance includes regular cleaning, lubrication of moving parts, and periodic checks on the machine’s calibration and alignment. SourcifyChina provides detailed maintenance manuals and support services.

What is the typical lead time for manufacturing and delivery?

The lead time typically ranges from 4 to 8 weeks, depending on the customization and current order volume. SourcifyChina maintains transparent communication regarding production and shipping timelines.

Can the pre-rolls machine be customized to specific requirements?

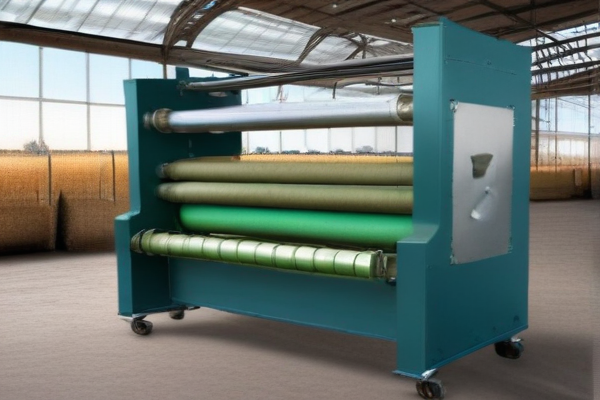

Yes, SourcifyChina offers customization options to meet specific requirements, including size adjustments, material selection, and added features. Customers can consult with SourcifyChina’s engineering team for tailored solutions.

What after-sales support does SourcifyChina provide?

SourcifyChina offers comprehensive after-sales support, including remote technical assistance, spare parts supply, and on-site service if needed. A dedicated customer service team is available to assist with troubleshooting and questions.

Are there training sessions available for operating the pre-rolls machine?

Yes, SourcifyChina provides training sessions for machine operators, which can be conducted either on-site or remotely. Detailed user manuals and instructional videos are also available.

How energy efficient are the pre-rolls machines from SourcifyChina?

SourcifyChina’s pre-rolls machines are designed to be energy efficient, utilizing advanced motors and control systems that reduce power consumption while maintaining high performance.

What warranty terms are offered with the pre-rolls machine?

SourcifyChina provides a standard 12-month warranty on their pre-rolls machines, covering parts and labor. Extended warranty options are also available upon request.