Sure! Here are some frequently asked questions (FAQ) and answers for sourcing a premade pouch packaging machine from SourcifyChina factory:

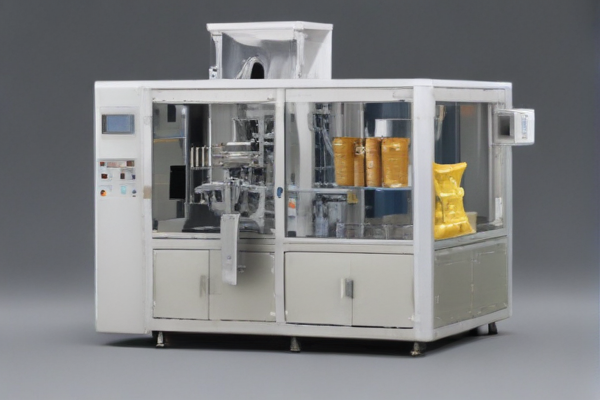

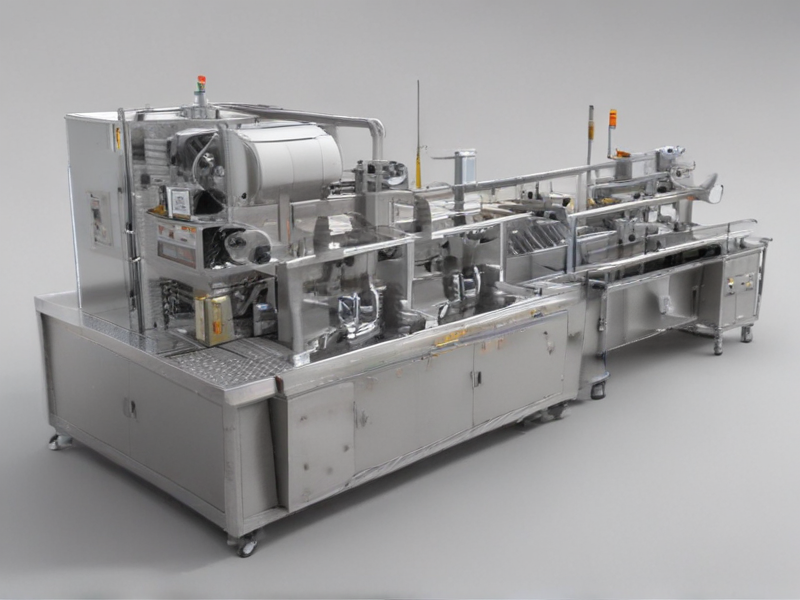

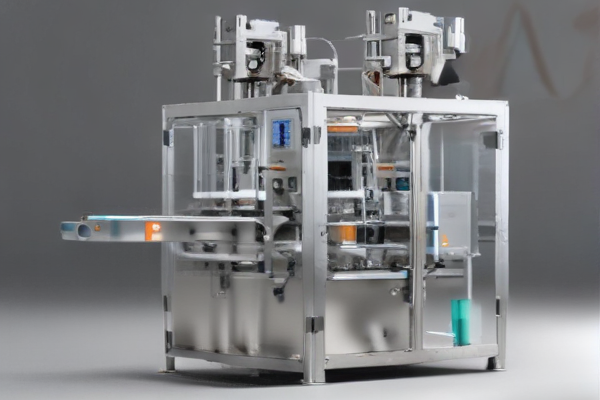

What types of premade pouch packaging machines are available at SourcifyChina?

SourcifyChina offers a variety of premade pouch packaging machines, including rotary, fill-seal, and vacuum pouch packaging machines suitable for different product types and pouch styles.

Can the machines handle different pouch sizes and materials?

Yes, the machines from SourcifyChina are designed to accommodate various pouch sizes and are compatible with a wide range of materials such as laminated films, plastic, paper, and more.

Are the machines customizable?

Yes, SourcifyChina provides customization options to tailor the machines as per specific requirements, including modifications in filling methods, sealing systems, and additional features like date coding.

What is the lead time for delivery?

The lead time varies based on the complexity and customization of the machine. Generally, it ranges from 6 to 12 weeks. Specific lead times will be confirmed during the order process.

Is installation and training provided?

Yes, SourcifyChina offers installation services and comprehensive training programs to ensure the smooth operation of the packaging machine at your facility.

What is the warranty period?

The standard warranty period for premade pouch packaging machines from SourcifyChina is typically one year, covering parts and labor. Extended warranties may be available upon request.

How does SourcifyChina handle after-sales service?

SourcifyChina provides robust after-sales support, including remote assistance, spare parts availability, and on-site repair services if necessary.

What are the payment terms?

Payment terms usually involve a deposit upfront, with the balance due before shipment. Specific payment terms can be negotiated based on your order and contract terms.

How can I get a quote or place an order?

To get a quote or place an order, you can contact SourcifyChina via their website, email, or phone. Provide your specific requirements to receive a detailed quotation and further instructions.

Are there any references or case studies available?

Yes, SourcifyChina can provide references and case studies upon request to showcase their expertise and the successful implementation of their packaging solutions in various industries.