Sure, here is a concise FAQ list for sourcing a premade pouch packing machine from SourcifyChina factory:

1. What types of premade pouch packing machines does SourcifyChina offer?

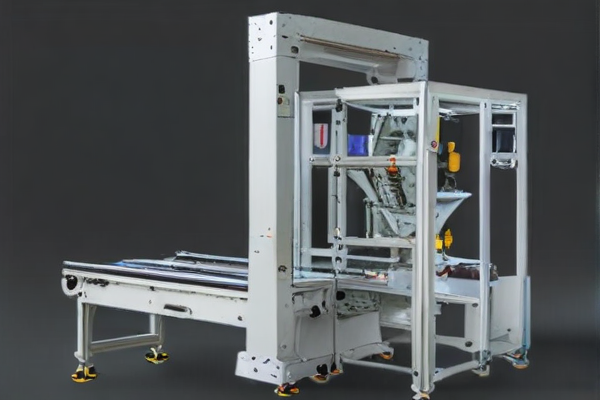

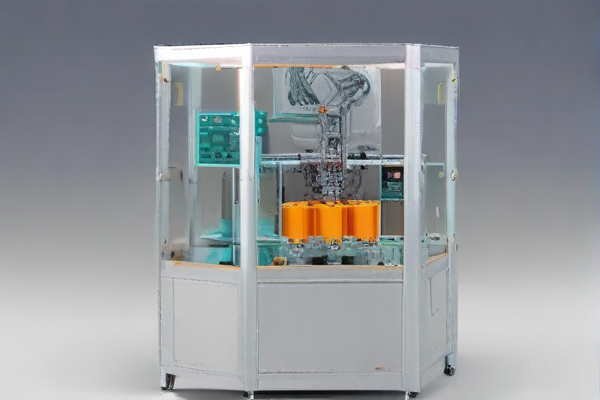

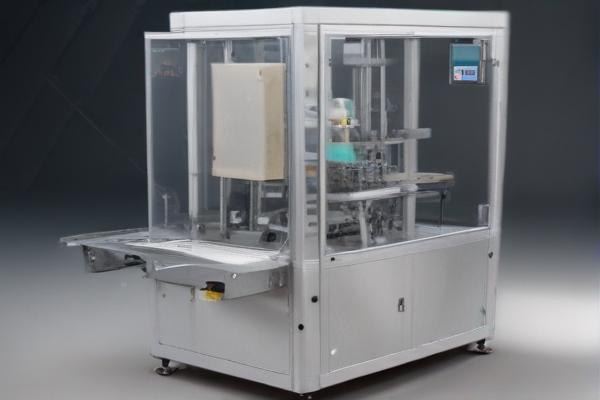

SourcifyChina offers a variety of premade pouch packing machines including horizontal and vertical models, suitable for filling and sealing different materials like powders, granules, liquids, and pastes.

2. What is the lead time for delivery?

The standard lead time is typically 4-6 weeks after order confirmation, but it can vary based on machine customization requirements and factory workflow.

3. Do you provide customization options?

Yes, SourcifyChina offers extensive customization options to meet your specific packaging needs, including various sizes, filling capacities, and additional features.

4. What are the payment terms?

The common payment terms are 30% deposit upfront and 70% balance before shipment. Other terms may be negotiable based on the order size and customer requirements.

5. Is there a warranty on the machines?

Yes, SourcifyChina provides a standard one-year warranty on all premade pouch packing machines, covering parts and labor. Extended warranties are also available upon request.

6. How can I ensure the machine quality?

Each machine undergoes rigorous quality control checks and testing before shipping. Customers are also welcome to visit the factory for inspection or request a third-party quality inspection.

7. Do you offer after-sales support?

Yes, we provide comprehensive after-sales support including installation guidance, operational training, troubleshooting, and spare parts supply.

8. Can you handle shipping logistics?

Yes, SourcifyChina can manage all aspects of shipping, including documentation, customs clearance, and delivery to your doorstep.

9. What certifications do your machines have?

Our machines are certified with CE, ISO, and other relevant industry standards ensuring compliance with international quality norms.

10. How do I get a quote?

To get a quote, please contact us through our website or email with your specific requirements. Our team will respond promptly with detailed information and pricing.

This concise FAQ should help prospective buyers get a clear understanding of sourcing premade pouch packing machines from SourcifyChina factory within the 300-word limit.