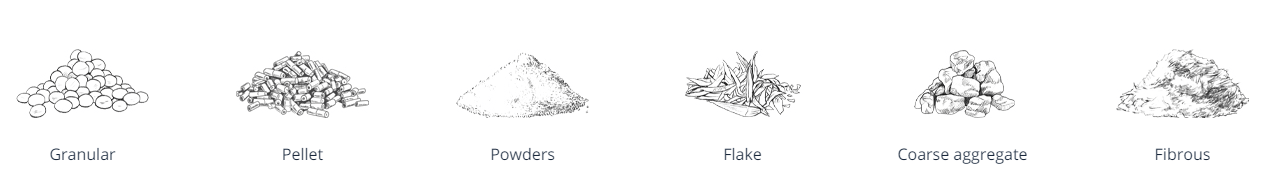

The open mouth bagging systems are specially crafted to efficiently bag free-flowing materials into open-mouth bags weighing between 5 and 50 kg each. These systems are well-suited for bagging a variety of powders used in the Food, Feed, Pet Food, Chemicals, and Minerals industries, such as antioxidants, citric acid, starch, additives, and lithium batteries.

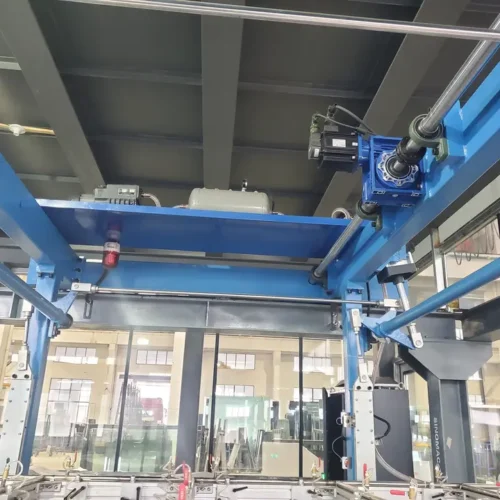

Featuring various feeding forms like Gravity Feeding, Single/Double Screw Feeding, Belt Feeding, Vibration Feeding, and Combined Feeding, these systems offer flexibility in handling different materials. The weighing form can be either net or gross weight scale, while bag mouth exhaust options include In-bag upper exhaust and inner bag degassing + upper exhaust.

Key Features of the Open Mouth Bagger:

- Automatic adjustments for quick product and bag changeovers

- Total bag top control

- Optimized dust control

- PLC controlled with user-friendly human machine interfaces (HMI)

- Easy to clean and maintain

- Compact design suitable for restricted packaging rooms

- Fully integrated gross or net weighing system

Machine Details include support for common bag closing devices, bag marking systems for empty or filled bags, product de-aeration, remote control panel, bag turning, and a full stainless steel design.

Applications of the Open Mouth Bagging Machine encompass packing powders with good fluidity such as starch, flour, tea powder, salt, etc. The machine is versatile and can be used for various applications including washing powder packaging, salt packing, rice packing, flour packing, beans packing, pet food packing, PVC packaging, and fertilizer packing.

Technical Parameters for Model Series FP300:

- Packable Products: Powder

- Bag Type: PE bags/ aluminum foil bags/ woven bags/ paper bags/ paper-plastic composite bags, etc.

- Roll Film: Diameter of roll film ≤1500mm, inner tube of roll film: 150mm (6 inches)

- Empty Bag Size: L(500-750mm), W(320-420mm)

- Packaging Weight: 20-50 kg/bag

- Packaging Speed: 300~600 bags/h

- Power: 3 kW

- Air Consumption: 200 NL/min

- Equipment Size (LWH): 2904 * 2920...

The working process involves pre-placing empty bags, taking an empty bag, opening the empty bag, supplying the empty bag, material filling, and concluding with holding the bag and heat sealing. The machine provides a reliable and efficient bagging solution for various industries.

[End of rewritten content]