List Technical Parameters of “agarbatti packing machine”

The agarbatti packing machine is a specialized device used to pack incense sticks or agarbattis in proper packaging material. These machines come in different models and designs, but all of them share some common technical parameters or features. Some of the technical parameters of an agarbatti packing machine include:

1. Production Capacity: The agarbatti packing machine can pack a certain amount of incense sticks within a given time period, typically measured in sticks per minute or hour. Production capacity largely depends on the machine’s design, motor power, and operator skill.

2. Material Handling: This parameter includes how the machine handles agarbatti sticks and what kind of packaging materials (e.g., plastic pouches, boxes, etc.) it can use. An efficient agarbatti packing machine should be able to handle a wide variety of agarbattis and packaging materials without compromising their quality.

3. Automaticity: The degree of automation in an agarbatti packing machine can vary from fully automatic to semi-automatic. Fully automatic machines require minimal operator intervention, while semi-automatic machines need manual adjustments and monitoring.

4. Accuracy: The machine should be able to pack agarbattis accurately, without under-filled or overfilled packaging. This parameter has a direct impact on the cost-effectiveness and customer satisfaction of the machine.

5. Durability: The machine should have a sturdy construction and use high-quality materials to withstand heavy usage for years without frequent maintenance.

6. Power Consumption: The amount of power an agarbatti packing machine uses is another important technical parameter. It should be designed to consume less power without compromising its performance.

7. Operational Safety: The machine should have safety features such as emergency stop buttons, safety guards, and safety sensors to prevent accidents.

Overall, the technical parameters of an agarbatti packing machine should be carefully considered before making a purchase. The choice of parameters will largely depend on the type of agarbattis to be packed, production requirements, and budget constraints.

List Product features of “agarbatti packing machine”

Agarbatti packing machines are specialized packaging machines that are used for packaging incense sticks. These machines are designed to streamline the production of agarbatti making it quicker, efficient and cost-effective. Here are some product features of agarbatti packing machines:

1. Advanced Technology – Modern agarbatti packing machines are built with advanced technology that allows them to package agarbattis quickly and with ease. They are designed to handle a high volume of agarbattis, which makes them ideal for commercial and industrial use.

2. Versatile – Agarbatti packing machines can pack different types of incense sticks such as bamboo, wood, and charcoal incense sticks. The machine can also be used to pack different sizes and shapes of agarbattis.

3. Easy to Operate – The operation of agarbatti packing machines is user-friendly. The machines come with easy to understand instructions so that anyone can learn how to operate them with minimal difficulty.

4. High-Speed – Agarbatti packing machines can pack up to 200 incense sticks per minute depending on the model, size and shape of the incense sticks and packaging style. This high-speed capacity of the machine helps incense-making businesses increase their production output and become more profitable.

5. Automatic Packaging – Agarbatti packing machines are designed with automatic packaging systems that give fast and efficient results. The machines will automatically package incense sticks and store them in designated places in various packets. This helps reduce labor costs, increases efficiency and also reduces the risk of repetitive strain injuries that can occur from manual packaging.

6. Cost saving -By reducing the labor costs, and increasing the speed and efficiency of packaging, the agarbatti packing machine significantly reduces the production costs of an incense-making company.

7. Low Maintenance Cost – Most agarbatti packing machines are built with durable material. Hence, the maintenance cost is low, which makes it an ideal investment in the long run.

In conclusion, agarbatti packing machines are essential tools that help incense-making businesses produce and package incense sticks more efficiently and cost-effectively. They help to streamline the entire process, improve productivity, reduce waste, and increase profitability. The choice of packaging machines depends on the production needs of your business.

List Application of “agarbatti packing machine”

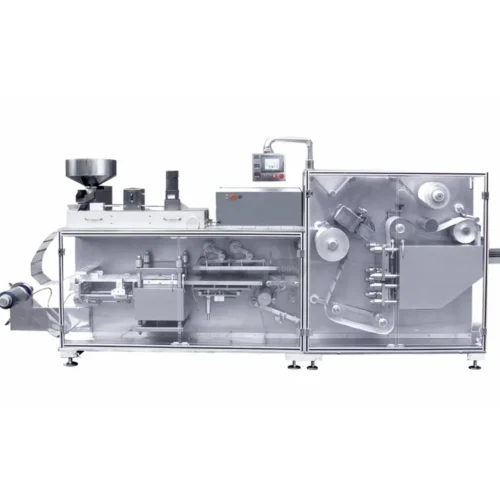

The agarbatti packing machine is an automated packaging machine that is used to pack incense sticks (agarbatti) into different quantities. This machine is designed to perform various tasks related to packing, counting, filling, and sealing of agarbatti’s, and offers numerous benefits to the manufacturer.

The application of agarbatti packing machines is highly effective for incense stick manufacturers who frequently face challenges in packing bulk quantities of agarbatti’s manually. Let’s explore some of the applications below.

1. Increased Productivity: An agarbatti packing machine can work 24*7 with very little upkeep. An accurately automated packaging machine can increase productivity, boost efficiency, and ultimately, lead to a rise in profits for the manufacturers.

2. Saves Time: The agarbatti packing machine can pack agarbatti sticks quickly and accurately without the need for manual labour. This helps save significant amounts of time and energy for the manufacturer, making their production process more efficient.

3. High-Quality Output: With agarbatti packing machines, high-quality incense sticks can be produced in a more consistent manner. Additionally, these machines are equipped with an automatic counting system that helps to track the quantity of agarbatti sticks packed, ensuring precision in their output.

4. Customisable Packaging Options: With the help of an agarbatti packing machine, manufacturers can provide customisable packaging options for their customers at competitive prices. An automatic packaging machine can take care of packaging in different quantities, shapes, and sizes, according to the manufacturer’s needs.

5. Cost-Effective: Investing in an agarbatti packing machine can be a cost-effective solution for incense stick manufacturers in the long run. It can help reduce labour costs, minimise manual errors, and eventually save significant amounts of money.

In conclusion, the agarbatti packing machine is a highly effective solution for incense stick manufacturers seeking to increase productivity and quality, reduce costs, and improve their product packaging options.

List Various Types of “agarbatti packing machine”

Agarbatti packing machines are designed to provide an effective and efficient packaging solution to the incense stick manufacturing industry. The packaging machine is an essential part of the agarbatti production line, which is responsible for packaging and sealing the incense sticks in a variety of packaging methods and materials.

Here are some common types of agarbatti packing machines that are available in the market:

1. Single-chamber packing machine – This type of agarbatti packing machine is ideal for small-scale packaging needs. It is used to package incense sticks in a single chamber and can handle up to 15-16 sticks per pack.

2. Multi-chamber packing machine – As the name suggests, this machine is capable of packaging multiple sticks in various chambers. It can handle a higher volume of sticks per pack, making it suitable for larger-scale production facilities.

3. Zipper pouch packing machine – This type of machine is designed to package incense sticks in airtight zipper pouches that can maintain the fragrance and quality of the incense sticks for a longer duration. This type of packaging is preferred by consumers who want to preserve the aroma of the incense sticks.

4. Automated packaging machine – This machine uses advanced technology to automate the packaging process, reducing the need for manual labor. This machine is ideal for large-scale production facilities that require high-speed packaging.

Overall, agarbatti packing machines play a crucial role in the manufacturing and packaging of incense sticks. Companies that use these machines can increase their production efficiency, reduce packaging costs, and cater to the diverse needs of their customers.

List The Process of “agarbatti packing machine”

The process of agarbatti packing machine involves several steps to ensure the smooth functioning of the machine and proper packaging of agarbattis. The steps are as follows:

Step 1: Preparation of Agarbattis

Agarbattis are prepared by mixing several ingredients like charcoal powder, wood powder, essential oils, etc. in a specific ratio. The mixture is then rolled into a bamboo stick, dried, and cut into desired sizes.

Step 2: Filling of Agarbattis in the hopper

The agarbatti packing machine has a hopper, where the prepared agarbattis are filled. The hopper is equipped with an adjustable vibro feeder that helps in feeding the agarbattis into the machine at a regular interval.

Step 3: Packaging Material Loading

The machine also has a packaging material loading slot, where the packaging material is loaded. The material may be paper pouches, polythene bags, or any other suitable material used for packaging.

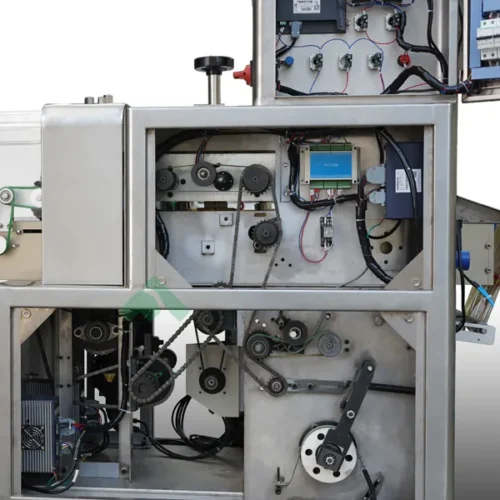

Step 4: Sealing rollers and cutting blades

The machine has sealing rollers and cutting blades, which seal and cut the packaging material according to the desired shape and size of the packets.

Step 5: Sensor-based Mechanism

The packaging is done with the help of a sensor-based mechanism that ensures the appropriate length of the agarbattis is packed without any error.

Step 6: Delivery Chute

Once the packaging is done, the packed agarbattis are then delivered through the delivery chute.

Step 7: Quality Check

The manufactured product undergoes quality checks before it is dispatched to the market. The checks ensure that the agarbattis meet the desired quality standards.

In conclusion, the agarbatti packing machine is a complex machine that involves several steps from agarbatti preparation to packaging. The machine ensures a smooth process and aids in mass production of agarbattis. The output of the machine is of high quality and meets the specific customer demands.

How to use “agarbatti packing machine”

Agarbatti or incense sticks are a popular product used in households and temples for their aromatic properties. With the increasing demand for incense sticks, manufacturers are in need of an efficient, cost-effective packaging solution. This is where the agarbatti packing machine comes in.

The agarbatti packing machine is designed to automatically pack incense sticks into various forms of packaging, including plastic bags, boxes, and pouches. The machine can be operated by a single operator, making it easy to install and operate.

The process of packaging incense sticks using the agarbatti packing machine involves the following steps:

1. Loading: The operator loads the agarbatti sticks into the loading hopper.

2. Filling: The agarbatti packing machine then fills the packaging material with incense sticks to the desired level.

3. Sealing: The packaging material is sealed using heat or ultrasonic technology to ensure the incense sticks are securely packaged.

4. Cutting: The packaging material is then cut to the required size using a cutting mechanism.

5. Finishing: The finished products are then discharged from the agarbatti packing machine.

The advantages of using the agarbatti packing machine include increased production capacity, improved product quality and consistency, reduced labor costs, and increased efficiency. The machine is easy to operate, reduces product waste, and minimizes the risk of product contamination.

In conclusion, the agarbatti packing machine is an essential tool for incense stick manufacturers looking to streamline their production process, increase efficiency, and reduce labor costs. By understanding how to operate and maintain the machine, manufacturers can keep up with the growing demand for incense sticks without sacrificing quality or productivity.

List Properties of “agarbatti packing machine”

Agarbatti packing machine is a specialized machine utilized in the packaging of agarbatti or incense sticks. With the growing demand for incense sticks, the packaging industry has progressed rapidly, providing a steady market for agarbatti packing machines. These machines are designed to optimize the speed of packing while ensuring a consistent outcome. Here are some of the properties of an agarbatti packing machine:

1. High Production Capacity: Agarbatti packing machines can pack a large volume of incense sticks in a short time. This feature is highly appreciated by agarbatti manufacturers who operate on a large scale.

2. Automatic Packaging: The machine is equipped with automation technology that enables automatic packaging of incense sticks. It utilizes servo technology, which ensures consistent filling of the packaging material.

3. Easy to Operate: Agarbatti packing machines are easy to operate as they come with user-friendly touch screens that provide real-time data on the packaging process and ensure easy maintenance of the machine.

4. Compact Design: The agarbatti packing machine has a compact design that saves space and is easy to install. The machine is highly flexible and can be customized to fit the specific needs of the client.

5. Durable: The packing machine is constructed with high-quality materials that ensure the machine’s longevity. Moreover, they are designed to operate at peak efficiency even in harsh environments, providing clients with maximum productivity.

6. Multiple Packaging Options: The machine can pack incense sticks in various packaging options, such as pouches, boxes, and packets. This feature enables manufacturers to provide customers with various packaging options, not limited to a particular size or style.

Overall, agarbatti packing machines are an integral part of the manufacturing industry’s growth, providing high-speed packaging solutions to meet the growing demand for incense sticks. Their high capacity, automation features, ease of operation, compact design, durability, and packaging flexibility make them the ideal choice for agarbatti manufacturers.

List “agarbatti packing machine” FAQ

Q1. What is an agarbatti packing machine?

An agarbatti packing machine is a machine used for packing incense sticks into different sizes of pouches and boxes. These machines are used in agarbatti making factories, where they help streamline the process of packaging the incense sticks.

Q2. What are the different types of agarbatti packing machines available in the market?

There are several types of agarbatti packing machines available in the market. The most common ones are vertical form-fill-seal machines, automatic pouch packing machines, and manual agarbatti packing machines. Each type has its own unique features and advantages.

Q3. What are the benefits of using an agarbatti packing machine?

Using an agarbatti packing machine can provide several benefits, such as increased production efficiency, reduced labor costs, decreased errors in packing, and better product quality. These machines also ensure that the incense sticks are packed in a hygienic and orderly manner.

Q4. Is an agarbatti packing machine easy to use?

Most agarbatti packing machines are designed to be user-friendly and easy to operate. Most come with a user manual and online tutorials. However, some machines may require some technical knowledge to operate, and training may be required to ensure that the machine is handled safely.

Q5. Do agarbatti packing machines require maintenance?

Yes, like all machines, agarbatti packing machines require regular maintenance to ensure optimal functionality. The frequency of maintenance will depend on the machine’s type and usage. Proper cleaning, lubrication, and replacements of worn-out parts are essential for the machine’s long-term durability.

Q6. Can agarbatti packing machines be customized?

Yes, most manufacturers provide the option of customizing the machine’s features, such as packaging speed, size, and type of packaging material. This allows the machine to be tailored to the specific needs of the client.

Overall, an agarbatti packing machine is a valuable investment for an incense stick manufacturer. It can help increase production efficiency, improve product quality, and reduce labor costs. By understanding the different types of machines and their functions, one can choose the machine that best suits their needs and maximize its benefits.