List Technical Parameters of “auto wrapping machine”

Auto wrapping machines are designed to streamline packaging processes in various industries. These machines are specifically designed to wrap products or items with plastic or stretch films. The following are the technical parameters of auto wrapping machines:

1. Size: Auto wrapping machines are available in different sizes ranging from small tabletop machines to large industrial machines.

2. Weight: Depending on the size, an auto wrapping machine can weigh from 50kg to more than 1000kg.

3. Power consumption: The power consumption of auto wrapping machines varies depending on their size, model and manufacturer. Nevertheless, most automatic wrapping machines work at minimal power consumption.

4. Wrapping speed: Auto wrapping machines offer different wrapping speeds depending on the model and make. Some industrial machines can wrap up to 180 pallets per hour, while smaller machines handle lower rates.

5. Wrapping height: The wrapping height of auto wrapping machines determines the maximum height limit of a load that the machine can handle. This parameter is critical to ensure the machine covers the entire package.

6. Film roll dimensions: The dimensions of the film roll vary from one auto wrapping machine to another. However, most industrial models can accommodate 500mm wide films with a thickness between 12-50 microns.

7. Control system: The control system of an auto wrapping machine is typically electronic, ensuring the use of pre-programmed selection and setting of operating parameters.

8. Accessibility: Automatic wrapping machines should be designed for easy accessibility, both for machine operation, maintenance, and any fault fixing.

Auto wrapping machines have become necessary for industries that require fast, efficient, and cost-effective packaging of products. These machines function automatically, depending on pre-programmed settings, allowing workers to focus on other activities such as loading, inspection or transportation.

List Product features of “auto wrapping machine”

Auto wrapping machine is a high-speed and efficient packaging machine that is used to wrap a variety of products automatically. It significantly increases productivity and reduces labor costs. Following are the product features of an auto wrapping machine:

1. High-speed wrapping: Auto wrapping machines can wrap the products at high speeds, which is one of the significant features of this device. The machines can wrap up to 60-80 products per minute, depending on the type of product.

2. Versatile: Auto wrapping machines are versatile and can handle different types of products, including bottles, cans, cartons, and other similar products.

3. Ease of use: Auto wrapping machines are straightforward to operate. They come with an intuitive user interface that allows operators to monitor and control the machine’s operation easily.

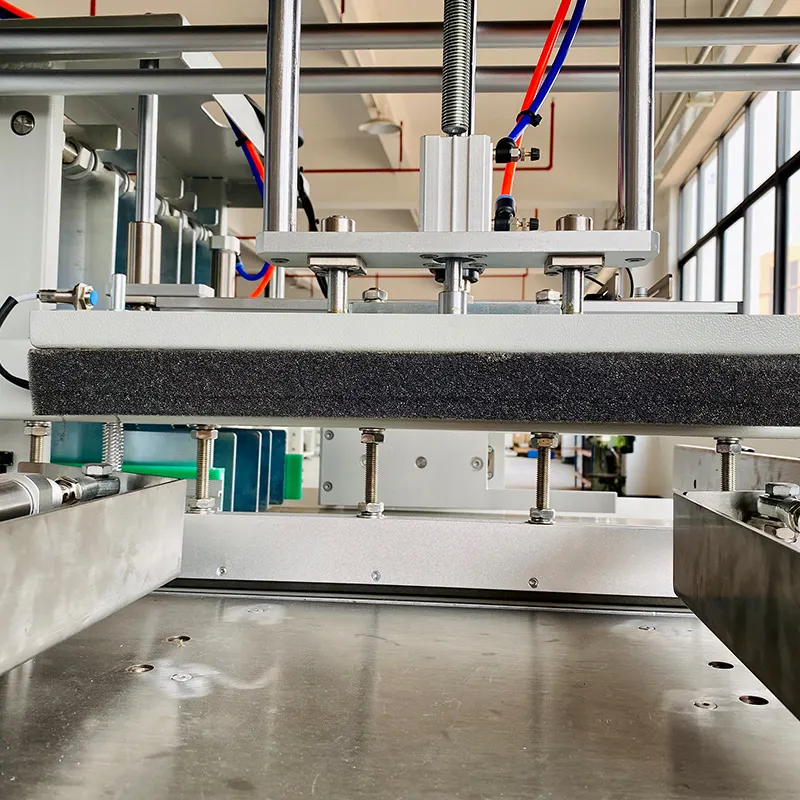

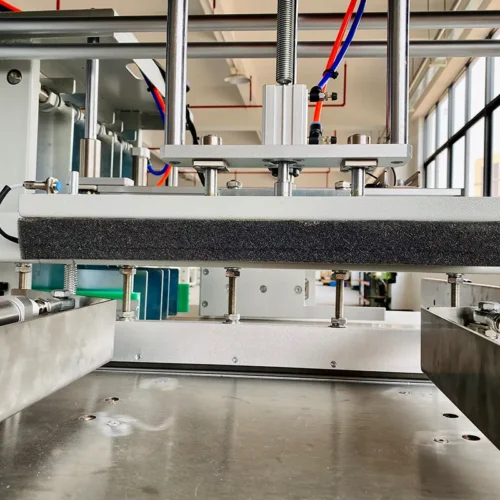

4. Durability: Auto wrapping machines are made of high-quality materials that make them durable and long-lasting. They can withstand the harsh conditions of the production environment and need little to no maintenance.

5. Quick-changeover: Auto wrapping machines can change the wrap film and settings quickly, which enables operators to keep up with varying production demands.

6. Automatic film tracking: Auto wrapping machines have an automatic film tracking system that ensures the accurate placement of the wrap film. This feature improves the quality of the finished products and minimizes wastage.

7. Safety features: Auto wrapping machines are equipped with multiple safety features, such as interlocks and emergency stop buttons, to prevent accidents and ensure operator safety.

8. Compact size: Auto wrapping machines are designed to take up minimal floor space, making them ideal for small to medium-sized production facilities.

9. Customizable: Auto wrapping machines can be customized to meet the specific production needs of the business. Companies can add additional features, such as label applicators and conveyors, to improve efficiency and productivity.

In Conclusion, Auto wrapping machines are essential equipment for companies that want to improve productivity, reduce labor costs, and produce high-quality products. They come with several features that make them versatile, easy to use, and safe. The machines are customizable and can help businesses meet their specific production requirements.

List Application of “auto wrapping machine”

The use of an auto wrapping machine, also known as a stretch wrapper, has increased significantly in recent years due to its efficiency in packaging various products. Some of the applications of an auto wrapping machine include:

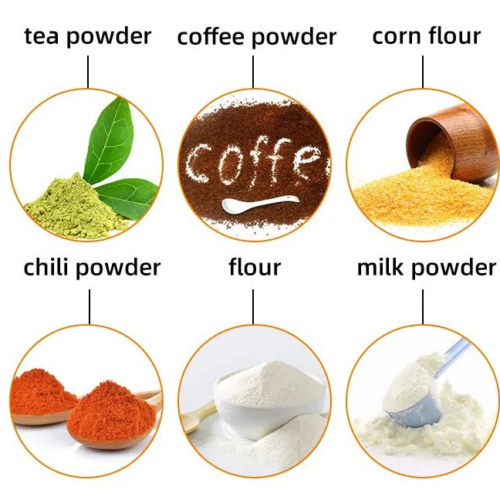

1. Food and Beverage Industry: An auto wrapping machine is used to package food and beverages in a hygienic way. It ensures that the products remain fresh and prevents contamination during transportation. The machine is ideal for wrapping products such as fruits, vegetables, meat, and dairy products.

2. Pharmaceutical Industry: The pharmaceutical industry uses an auto wrapping machine to wrap medicines, pills, and capsules. The machine guarantees the safety of the drugs during transportation, ensuring that they remain in their original condition. Additionally, the machine reduces the chances of tampering, ensuring safety for the end-users.

3. Industrial Packaging: The machine is used to wrap heavy-duty products such as industrial equipment, machinery, and construction materials. The stretch wrapping process ensures that the products are securely packaged, preventing damage during transportation.

4. E-commerce Industry: With the rise of online shopping, the e-commerce industry has embraced the use of an auto wrapping machine. The machine helps in wrapping various products such as electronics, jewelry, and clothes. The use of the machine has resulted in an increase in customer satisfaction due to the safe delivery of products.

5. Pet Food Industry: The pet food industry uses auto wrapping machines to package pet food products. It ensures that the products remain fresh, and the strong stretch wrap keeps the products safe during transportation.

In conclusion, an auto wrapping machine has numerous applications, from packaging food products, pharmaceuticals, industrial equipment, e-commerce products, and pet food products. The machine guarantees safety in the packaging process, ensuring that the products remain in their original condition during transportation. Its use has resulted in an increase in efficiency, customer satisfaction, and product safety.

List Various Types of “auto wrapping machine”

Auto wrapping machines are essential packaging tools in the manufacturing industry and are used to wrap products with films or sheets of plastic, paper, or other materials. There are various types of auto wrapping machines available in the market that cater to diverse packaging needs. Here are some of the most commonly used auto wrapping machines:

1. Semi-Automatic Stretch Wrapping Machine: This is a basic wrapping machine that wraps pallets with stretch wrap films. It is ideal for small businesses that do not require high-speed wrapping systems.

2. Fully Automatic Stretch Wrapping Machine: This type of machine wraps pallets with stretch wrap films automatically. It is ideal for larger businesses that require high-speed wrapping systems.

3. Shrink Wrapping Machine: This machine uses heat to shrink the wrapping film, making it fit snugly around the product. It is ideal for packaging food products and other products that need to be tamper-proof.

4. Horizontal Form-Fill-Seal Machine: This machine forms a bag from a roll of film by sealing the ends, fills the bag with the product, and seals the top of the bag. It is ideal for packaging food products such as snacks and candies.

5. Vertical Form-Fill-Seal Machine: This machine forms a bag from a roll of film, fills the bag with the product, and seals the top of the bag. It is ideal for packaging granular products such as coffee, sugar, and rice.

6. Overwrapping Machine: This machine wraps a secondary layer around a product that is already in a primary package. It is ideal for packaging small items such as chocolates and candies.

7. Tray Wrapping Machine: This machine wraps a plastic film around trays of products such as meat and poultry.

In conclusion, auto wrapping machines are essential packaging tools that increase the efficiency of the packaging process. Businesses should choose the type of auto wrapping machine that best suits their specific packaging needs.

List The Process of “auto wrapping machine”

An auto wrapping machine is a type of equipment used for packaging different products for distribution and sale. It simplifies the packaging process by automating it instead of manually wrapping each product. The following are the steps involved in the process of an auto wrapping machine.

1. Load the products – The first step in the process of an auto wrapping machine is to load the products onto the conveyor belt or other loading mechanism. It is important to ensure that the products are loaded correctly for the wrapping process to work efficiently.

2. Wrapping – The wrapped material is then pulled out and cut to the desired length. The wrapping material could be plastic, paper, or another wrapping material. The wrapping process is usually controlled using a computer. The wrapping machine will be set to wrap certain types of products to specific measurements.

3. Sealing – After the wrapping material is applied to the product, the next step is sealing it. This can be accomplished using heat, pressure, or adhesive.

4. Cutting – Once products are wrapped, the auto wrapping machine typically cuts them into individual packages. Depending on product type, some machines can individually weigh packages as well as cut them.

5. Collection and Distribution – At this stage, the wrapped and packaged products will be collected, usually on a collection table or conveyor belt, then transported to the packaging area. After this, the packaged products will be distributed to stores or any other locations where they will be sold or consumed.

In conclusion, auto wrapping machines simplify the complicated process of wrapping, sealing, and cutting products. They work to ensure that products are wrapped to the right weight, size, and volume. This leads to increased efficiency and productivity in the packaging and distribution process.

How to use “auto wrapping machine”

Auto wrapping machines are an essential piece of equipment in many industries. They are commonly used in the food, pharmaceutical, and manufacturing industries to wrap products for preservation, protection, and presentation.

To use an auto wrapping machine, there are several steps to follow. First, make sure that the machine is properly installed and functioning correctly. Then, select the appropriate wrapping material, such as shrink wrap or stretch film, and load it onto the roll holder of the machine.

Next, adjust the machine’s settings according to the dimensions and weight of the product being wrapped. This may include adjusting the wrapping speed, film tension, and temperature settings.

Once the machine is properly set up, place the product onto the conveyor belt or turntable, and activate the machine to begin the wrapping process. The machine will automatically wrap the product with the chosen wrapping material, and may also apply labels or heat seals as necessary.

After the wrapping process is complete, remove the wrapped product from the machine and repeat the process for additional products as needed.

Overall, auto wrapping machines offer many benefits to businesses, including increased efficiency, reduced labor costs, and improved product presentation. By following these simple steps, businesses can make the most of this valuable piece of equipment and improve their overall production process.

List Properties of “auto wrapping machine”

An auto wrapping machine is a piece of equipment commonly found in manufacturing facilities, which is used to package products automatically. The machine operates by wrapping products in layers of material, and sealing the layers together to create an air-tight seal. The following are some of the key properties of an auto wrapping machine:

1. High-speed operation: One important feature of auto wrapping machines is their ability to package products quickly, typically at rates of up to 60 packages per minute. This means that they are suited for high-volume production environments.

2. Versatility: Auto wrapping machines are designed to handle a wide range of products, from small items such as candy and gum to larger items like boxes and bags. This makes them suitable for use in many different industries, including food and beverage, pharmaceutical, and electronics.

3. Customizable settings: Most auto wrapping machines come equipped with settings that can be customized to match the specific needs of the product being packaged. This might include choosing the number of layers of wrapping, adjusting the temperature of the sealing process, and determining the speed of the machine.

4. Reliability: Auto wrapping machines are designed to operate continuously, with minimal downtime. This means that they are highly reliable, which is crucial in manufacturing environments where any delay or malfunction could lead to significant production losses.

5. Cost-effective operation: Auto wrapping machines are cost-effective for manufacturers because they require minimal labor, which reduces the overall cost of production. Additionally, many machines are designed to use cost-efficient materials, such as stretch wrap, which reduces the cost of packaging.

Overall, auto wrapping machines are an essential piece of equipment for manufacturers seeking to improve their productivity and efficiency, while reducing their packaging costs. By understanding the key features and capabilities of these machines, manufacturers can choose the right equipment to meet their needs and improve their bottom line.

List “auto wrapping machine” FAQ

1. What is an auto wrapping machine?

An auto wrapping machine is a piece of equipment that is built to wrap objects tightly and neatly. It has become an essential tool in various industries, such as food, pharmaceuticals, and retail, as it offers efficiency and reduces labor costs.

2. How does an auto wrapping machine work?

Auto wrapping machines work by feeding products into the machine and wrapping them tightly in a plastic film or other packaging material. The machine adjusts the wrapping material’s tension and speed to match the product’s characteristics, ensuring a tight and secure wrap.

3. What kind of products can be wrapped using an auto wrapping machine?

Auto wrapping machines can wrap a wide variety of products, including food products, such as fresh produce, meat, and baked goods, pharmaceutical products, electronics, and gifts.

4. What are the benefits of using an auto wrapping machine?

Using an auto wrapping machine offers several benefits, including increased productivity, reduced labor costs, improved product hygiene, consistent wrapping quality, and reduced product waste.

5. Can an auto wrapping machine be customized to suit specific needs?

Yes, an auto wrapping machine can be customized to suit specific customer needs and preferences. Customers can request modifications to the machine’s size, speed, and materials used to wrap products.

6. What is the maintenance requirement for an auto wrapping machine?

Auto wrapping machines require regular maintenance to ensure optimal performance and longevity. Routine maintenance tasks include cleaning, lubrication, belt and roller inspections, and replacing worn-out parts.

7. What is the lifespan of an auto wrapping machine?

The lifespan of an auto wrapping machine depends on various factors such as usage frequency, maintenance, and quality of materials used. However, a typical lifespan for an auto wrapping machine is between 5-15 years.

8. Is training required to operate an auto wrapping machine?

Yes, operators require training to operate an auto wrapping machine safely and effectively. Manufacturers provide instructional manuals, online resources, and on-site training to ensure that operators understand how to operate the machine correctly.