Secondary Packing - Automatic Carton Box Packing Line

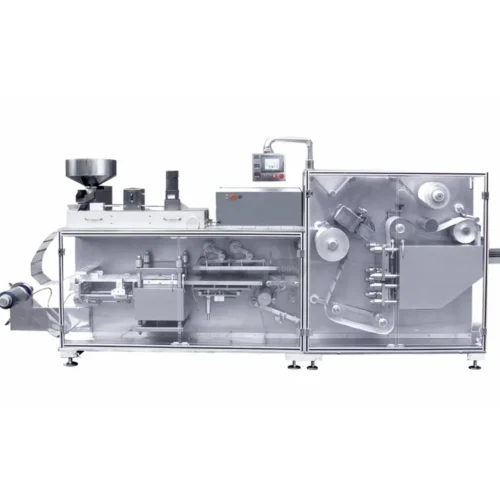

The secondary packaging machinery consists of an automatic cartoning machine that includes a carton erector, automatic packing of bags or boxes into cartons, carton sealing, auto baler, and conveyors.

The automatic cartoning machine in the secondary packing line comes in different types based on how the materials are loaded into the carton:

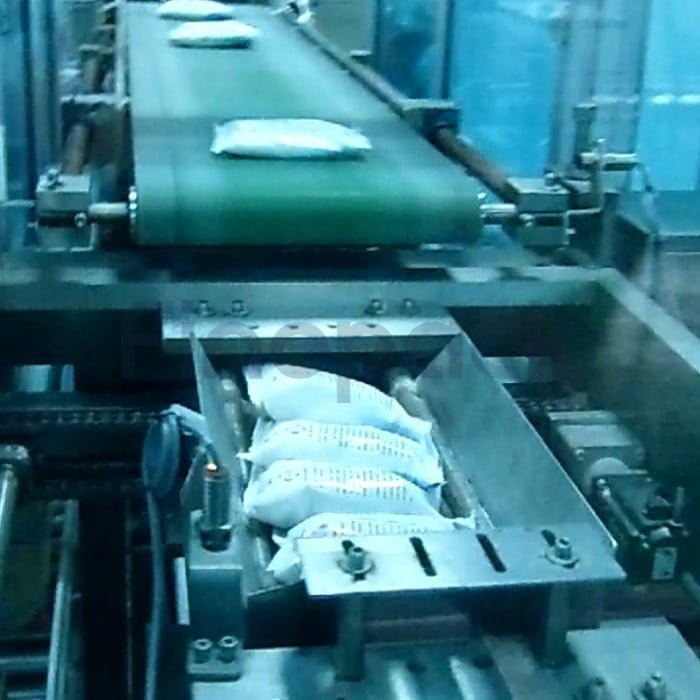

1. Drop Box Packing Line (packing bags into carton)

2. Grab Sucker Carton Box Packing Line (top-loading boxes into case packer)

3. Side Push Type Packing Line (boxes into carton)

Technical Specifications:

- Bag capacity: 5~12 cases per minute

- Configuration: The system is driven by Siemens servo motors

- Cylinder: SMC (Japan)

- Solenoid valve: SMC (Japan)

- Touch screen: Mitsubishi

- PLC: Mitsubishi (Model number to be confirmed during production)

- The system utilizes Mitsubishi PLC and touch screen for machine control

- Air pressure: ≥5kgf/cm²

Machine Details:

[Include details of the specific packaging machine here.]Packaging Machine Working Process:

[Pictorial representation or step-by-step explanation of the working process.]Packing Sample:

[Image or description of a sample packing output.]Factory Gallery:

[Images of the production facility and machinery in action.]Related Posts:

- Automatic 25kg Bagging Machine

- 50 kg Bag Packing Machine

- Heavy Bag Packaging Machine

- Vacuum Packing Machine