List Technical Parameters of "automatic lamination machine"

Automatic lamination machine is a modern equipment that is used to laminate various types of materials such as paper, cardboard, film, and others. The technical parameters of the machine are as follows:

1. Maximum lamination width: This is the maximum width of the material that can be laminated. It can range from 600mm to 1800mm.

2. Maximum laminating speed: This is the maximum speed at which the machine can laminate the material. It can range from 50m/min to 150m/min.

3. Laminating temperature: This is the temperature at which the machine can laminate the material. The temperature can range from 0°C to 200°C.

4. Laminating pressure: This is the pressure at which the machine can laminate the material. The pressure can range from 5kg/cm2 to 20kg/cm2.

5. Heating system: The heating system of the machine is responsible for maintaining the required temperature for lamination. There are different types of heating systems, including electric, infrared, and hot oil.

6. Unwinder and rewinder: The machine has unwinder and rewinder units that are responsible for feeding the material and removing the laminated material, respectively.

7. Control system: The machine has a control system that is responsible for controlling the parameters such as temperature, speed, pressure, and others.

8. Material thickness: The machine can laminate materials of different thicknesses. The thickness can range from 80gsm to 600gsm.

9. Type of material: The machine can laminate different types of materials such as paper, cardboard, film, and others.

10. Power supply: The machine requires a power supply of 220V/380V AC, 50Hz/60Hz.

The automatic lamination machine is a versatile and efficient machine that can perform various lamination tasks quickly and accurately. The machine can be used in various industries such as packaging, printing, publishing, and others. With its advanced features, the machine ensures high-quality lamination with minimum wastage.

List Product features of "automatic lamination machine"

An automatic lamination machine is a device used for covering printed or plain paper, cardboards, or other surfaces with a thin layer of plastic or lamination films. This process enhances the durability of the printed material by making it resistant to wear and tear, water, and stains. The following are some product features of an automatic lamination machine:

1. Speed: An automatic lamination machine can cover a high volume of materials in a short period, thus increasing productivity.

2. Multiple Usages: The machine can laminate various types of documents and materials in sizes ranging from A4 to larger sheets.

3. Easy to Operate: The device is user-friendly, making it easy to operate, even for novice users. The machine also features a control panel where the operator can set the temperature, speed, and pressure for optimal performance.

4. Automatic Sensor: This feature enables the machine to automatically detect the size and thickness of the material, thus preventing wastage of laminating films.

5. Versatility: An automatic lamination machine can use different types of laminating films, including gloss, matte, and thermal films.

6. Anti-jamming System: The machine has an anti-jamming system that adjusts the speed, temperature, and pressure to prevent wrinkling and bubbling of laminating films.

7. Energy-saving: The equipment's automatic shut-off feature helps reduce power consumption when the machine is not in use, thus saving energy.

8. Maintenance: The device requires minimal maintenance, with regular cleaning and occasional replacement of parts.

9. Warranty: An automatic lamination machine comes with a warranty period that ensures the machine's quality and guarantees its performance for a specified period.

10. Portability: Some models are portable, making them ideal for use in small spaces or remote locations.

Overall, an automatic lamination machine is a valuable asset for businesses and individuals that require the durable and professional-looking finish of laminated materials. The device's flexibility, speed, and ease of use make it an essential tool for any printing and document production facility.

List Application of "automatic lamination machine"

Automatic lamination machines have multiple applications in various industries. Here are some of the significant applications:

1. Printing Industry: Automatic lamination machines are used in the printing industry to laminate different types of documents, such as brochures, flyers, and ID cards, for durability and protection. Laminating paper ensures that the ink does not smudge or fade, and the paper stays good for a more extended period.

2. Packaging Industry: Packaging is one of the significant applications of automatic lamination machines. The machines can laminate outer packaging materials of different products such as food, cosmetic, pharmaceuticals to add protection and attractive finish.

3. Manufacturing Industry: Automatic lamination machines are used in the manufacturing industry to laminate various parts of a product to add value and durability. For example, laminating aluminum sheets can help to prevent rust and degradation in outdoor applications.

4. Automobile Industry: The automobile industry uses automatic lamination machines to laminate interior fabrics to make them durable and stain-resistant. The machines are also used to laminate car windows to improve their shatter resistance and reduce glare.

5. Construction Industry: Automatic lamination machines are used in the construction industry to laminate building materials such as flooring, windows, and siding to add strength and protection against harsh weather conditions.

6. Educational Industry: Automatic lamination machines are extensively used in the educational sector to laminate posters, charts, and study materials to facilitate reuse and protect them from damage.

7. Government and Defense Industry: The automatic lamination machines are used to laminate identity cards, passport, access cards, and other sensitive documents such as classified documents, defense blueprints to ensure longevity and protection against any element.

In conclusion, automatic lamination machines have a wide range of applications in multiple industries. They are essential for adding protection and longevity while enhancing the aesthetic value of a product document, and the machine is cost-effective.

List Various Types of "automatic lamination machine"

Automatic lamination machines are highly automated machines that are designed to provide a wide range of lamination solutions. Lamination machines are mostly used in packaging, printing, laminating industries.

There are various types of automatic lamination machines, each designed to cater to specific needs and requirements. The following are a few types of automatic lamination machines used for different applications in industrial settings:

1. Standard Automatic Lamination Machine: This type of automatic lamination machine is the most common in the market. It is designed to laminate papers, photos, cards, and other materials. These machines are mostly found in print shops, schools, and offices.

2. Pouch Lamination Machine: Pouch laminators are used for laminating small documents including photos, ID cards, and business cards. These machines use heated pouches to seal the plastic laminate onto the materials. They are perfect for applications that do not require high-volume laminating.

3. Roll-to-Roll Lamination Machine: Roll-to-roll lamination machines are designed to laminate large volume materials, including banners, posters, and signage. These machines use rolls of film and substrate to laminate materials continuously.

4. Cold Lamination Machine: Cold lamination machines use cold adhesives instead of heat to laminate materials. They are suitable for heat-sensitive materials, photographs, and other documents that cannot withstand heat.

5. Hot and Cold Lamination Machine: This type of lamination machine provides both hot and cold lamination options in a single device. This machine can laminate heat-sensitive documents as well as thick plastic materials.

6. Industrial Lamination Machine: Industrial lamination machines are designed to laminate high-volume and large-sized materials. These machines are mostly used in the printing and packaging industry.

In conclusion, automatic lamination machines are essential machines in various industries. They provide high-quality lamination solutions for a wide range of materials and documents. The above-listed types are just a few of the numerous types available in the market.

List The Process of "automatic lamination machine"

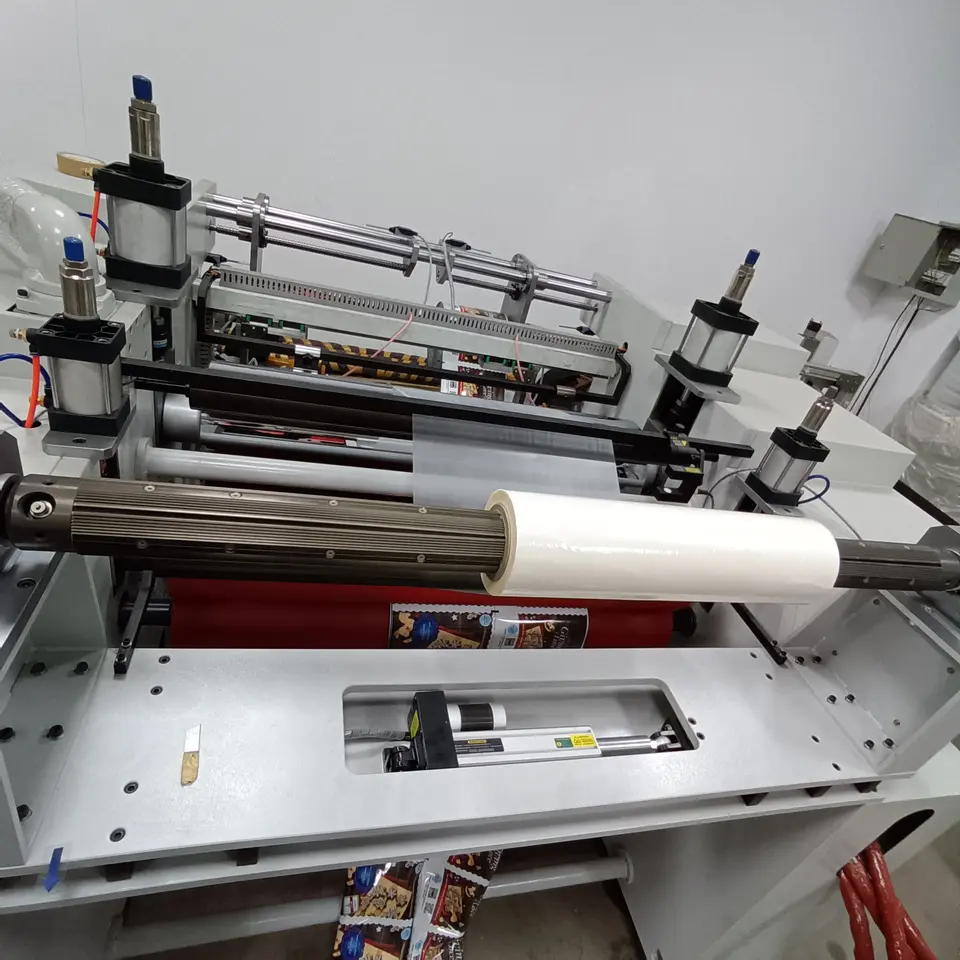

An automatic lamination machine is a type of equipment that binds two or more layers of materials together, usually consisting of a substrate, adhesive, and a protecting film. Below are the processes of an automatic lamination machine:

1. Material Loading: Materials like paper, fabrics, and films are loaded into the machine, usually on a reel, which unwinds as the lamination process takes place.

2. Cleaning and Coating: The materials undergo cleaning to remove any foreign particles and then proceed to the coating process. The materials are coated with adhesive or glue to prepare them for lamination.

3. Lamination: The materials are passed through a series of rollers, sandwiching the adhesive layer between the substrate and protecting film. The rollers apply pressure to ensure an even bond between the layers.

4. Trimming: After lamination, edges are trimmed off to produce neat and uniform-sized final products.

5. Finishing: Additional finishing processes like cutting, folding, and die-cutting take place to produce the final product in the desired shape and size.

6. Quality Control: The finished products undergo quality control checks to ensure they meet the required specifications and standards.

7. Packaging: The final products are packaged and prepared for distribution.

In conclusion, an automatic lamination machine is a vital equipment for industries that require lamination on a large scale. Its ability to handle many materials, provide even pressure, and produce neatly finished products makes it a preferred choice for many industries.

How to use "automatic lamination machine"

An automatic lamination machine is a device that is used to apply a protective layer on printed materials, documents, and photos. Using it is easy and straightforward. It saves time and effort, and the results are fantastic.

Here are the steps to follow when using an automatic lamination machine.

Step 1: Plug in the machine and turn it on.

Before you start using the machine, ensure it is plugged in to a power source and turned on.

Step 2: Set the temperature for the lamination film.

Next, set the temperature for the lamination film that you want to use. Normally, the machine comes with a chart that indicates the recommended temperature levels for different types of laminating films.

Step 3: Place the document on the feeding tray.

The feeding tray is located at the front of the machine. Place your document face up on the tray.

Step 4: Insert the lamination film.

Insert the lamination film into the machine and make sure it's fed through the rollers.

Step 5: Adjust the speed settings.

Normally, an automatic lamination machine has adjustable speed settings that allow you to set the speed at which the document goes through the machine. This is important because some documents may require a slower speed to ensure the lamination is a success.

Step 6: Press the "Start" Button.

Once everything is set up correctly, press the "Start" button, and the machine will start laminating the document.

Step 7: Trim the edges.

After the laminating process is complete, trim the edges of the document using a paper cutter or scissors.

In conclusion, an automatic lamination machine is an essential tool in any office. By following these simple steps, you can achieve professional lamination results in no time.

List Properties of "automatic lamination machine"

An automatic lamination machine is a device that automatically laminates documents or other flat materials by applying a layer of clear plastic film on both sides of the document. It is a fast, efficient, and cost-effective way of protecting and enhancing the appearance of printed materials such as photographs, certificates, posters, or business cards.

One of the key properties of an automatic lamination machine is its automation. This means that the machine can automatically feed the documents, apply the film, cut it to size, and stack the laminated sheets without requiring any manual intervention. This feature makes the process faster, more accurate, and more consistent.

Another important property of an automatic lamination machine is its speed. These devices can laminate up to 30 sheets per minute, making them ideal for high-volume jobs such as in print shops, copy centers, or busy offices. Additionally, some models can laminate larger documents up to A3 size, which expands their range of applications.

Moreover, an automatic lamination machine is versatile and can handle a variety of films and materials. It can laminate documents with thicknesses ranging from 80-250g/m2, and with film thicknesses up to 250 microns. Also, certain machines can handle different kinds of film finishes, including matte, gloss, or textured.

Automatic lamination machines are also designed to be user-friendly, with intuitive controls and easy-to-change film rolls. They have safety features such as automatic shut-off and jam-release mechanisms that ensure users' safety and prevent damage to the machine.

Finally, an automatic lamination machine is a cost-effective investment because it reduces material waste, increases productivity, and delivers professional results. It saves time and labor costs associated with manual lamination and ensures the longevity of the laminated documents, reducing reprint and reprinting costs.

Overall, an automatic lamination machine is a versatile, fast, and cost-effective solution for protecting and enhancing the appearance of printed materials. Its automation, speed, versatility, user-friendliness, and cost-effectiveness make it an indispensable tool for businesses of all sizes that require reliable and efficient lamination capabilities.

List "automatic lamination machine" FAQ

1. What is an automatic lamination machine?

An automatic lamination machine is a machine that is used to laminate a range of documents at an extremely fast pace, with different types of laminates.

2. What are the benefits of using an automatic lamination machine?

Using an automatic lamination machine provides a range of benefits, such as consistent performance, high efficiency, high productivity, low cost of ownership, increased safety, and easy operation.

3. What types of laminates can an automatic lamination machine handle?

An automatic lamination machine can handle various types of laminates, such as hot and cold laminates, PVC and PET laminates, Gloss and Matt laminates, and thermal and non-thermal laminates.

4. What are the sizes of laminates that an automatic lamination machine can handle?

The sizes of laminates that an automatic lamination machine can handle range from A4 to large formats such as A0.

5. How fast can an automatic lamination machine laminate a document?

The speed at which an automatic lamination machine can laminate a document varies, but most machines can laminate up to 100 meters per minute.

6. How does an automatic lamination machine work?

An automatic lamination machine has rollers that work together to apply the laminate onto the document, and the document is then passed through a heated section or pressurized rollers that activate the adhesive layer, bonding the laminate onto the document.

7. Is an automatic lamination machine expensive?

The cost of an automatic lamination machine can vary depending on its features, type, and size. However, compared to the cost of manual lamination machines, automatic machines are more expensive.

8. Can an automatic lamination machine laminate all types of documents?

Automatic lamination machines can laminate all types of documents, such as posters, brochures, and ID cards. However, it’s important to note that some documents may require specialized lamination, and in such cases, an alternative method may need to be used.

9. How often does an automatic lamination machine require maintenance?

An automatic lamination machine requires regular maintenance to ensure optimal performance and longevity. Regular service and cleaning are necessary to prevent damage or malfunction of the machine.

10. Who should use an automatic lamination machine?

Automatic lamination machines are ideal for businesses, schools, print shops, and individuals who frequently need to laminate documents. These machines are a great investment for those looking to increase efficiency while reducing costs in the long term.