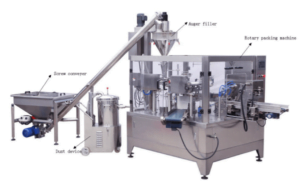

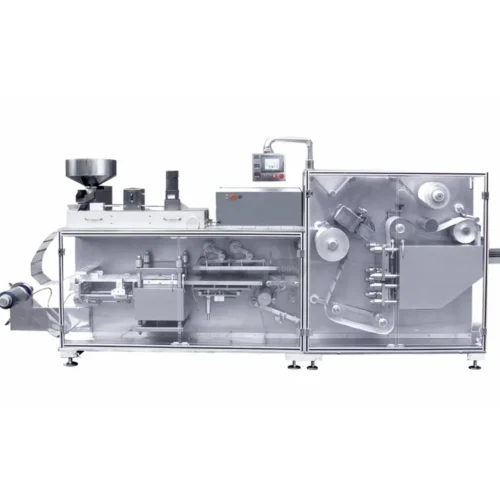

List Technical Parameters of "bag filling machine"

Sure, here are the key technical parameters of a bag filling machine:

1. Filling Capacity: The volume or weight the machine can handle, often specified in liters, kilograms, or pounds per bag.

2. Filling Speed: The rate at which the machine can fill bags, typically measured in bags per minute (BPM).

3. Bag Types: Compatible bag styles, such as pre-formed bags, open-mouth bags, and valve bags.

4. Bag Sizes: Range of bag sizes the machine can accommodate, including variations in width, length, and gusset depth.

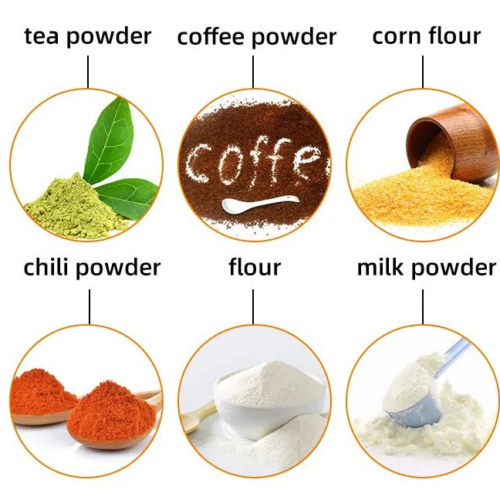

5. Materials Compatibility: Types of materials the machine can fill, such as powders, granules, pellets, or liquids.

6. Filling Accuracy: The precision of the filling process, often expressed as a percentage of deviation (+/-).

7. Material Contact Parts: Specifications on parts that come in contact with the product, usually made of stainless steel for hygiene and corrosion resistance.

8. Power Requirements: Electrical specifications for the machine, including voltage, phase, and frequency.

9. Air Consumption: For pneumatic components, this is usually measured in cubic feet per minute (CFM) or liters per minute (L/min).

10. Control System: Type of automation and interface, such as PLC (Programmable Logic Controller) with HMI (Human Machine Interface) touch screens.

11. Sealing Mechanism: Methods for sealing bags, such as heat sealing, sewing, or ultrasonic sealing.

12. Weight: The machine's overall weight, which can impact installation and mobility considerations.

13. Dimensions: Physical footprint of the machine, including width, length, and height.

14. Output Conveyors: Specifications of attached conveyors for moving filled bags, often with details on speed and adjustability.

15. Safety Features: Includes emergency stop buttons, guards, and interlocks to ensure operator safety.

16. Maintenance Requirements: Information on maintenance schedule, ease of access for service, and availability of replacement parts.

17. Compliance Standards: Relevant certifications and standards met by the machine, such as ISO, CE, or GMP (Good Manufacturing Practice).

18. Optional Features: Additional functionalities like zippers, tear notches, and back-flush systems for inert gas filling, depending on customization options available.

Understanding these parameters is crucial for selecting the right bag filling machine for specific production needs.

List Product features of "bag filling machine"

Sure! Here are the key product features of a bag filling machine:

1. High-Speed Operation: Capable of filling bags at a rapid pace, ensuring efficiency in large-scale production environments.

2. Accuracy: Equipped with advanced weight sensors for precise measurement, minimizing material waste and ensuring product consistency.

3. Versatility: Compatible with various bag types and sizes, such as paper, plastic, and woven bags. Suitable for a wide range of products including grains, powders, pellets, and other bulk materials.

4. Automated Control: Features programmable logic controllers (PLCs) and touch-screen interfaces for easy setup, monitoring, and adjustment of machine parameters.

5. Durability and Reliability: Constructed with high-quality stainless steel and other robust materials to withstand heavy-duty use and harsh environments.

6. Easy Maintenance: Designed with minimal moving parts and easy access points for cleaning and maintenance, reducing downtime and prolonging machine life.

7. Safety Features: Includes emergency stop buttons, guards, and interlocking systems to ensure operator safety during operation.

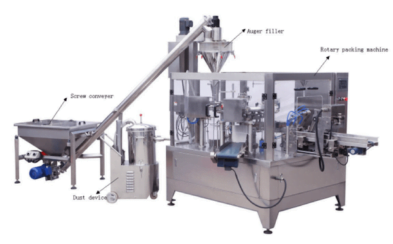

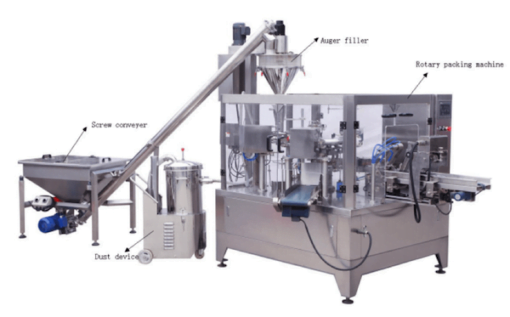

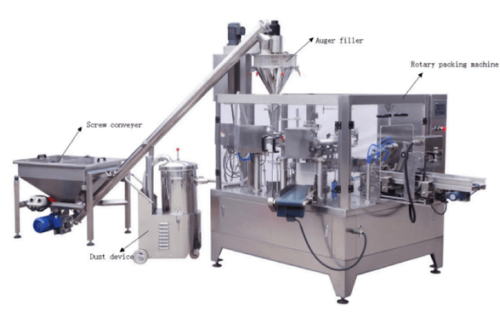

8. Dust Control: Incorporates dust collection and control systems to maintain a clean working environment and improve operator health and safety.

9. Integration Capabilities: Easily integrates with upstream and downstream equipment such as conveyors, sealers, and palletizers for a complete, automated packaging line.

10. Energy Efficiency: Optimized to consume minimal energy, contributing to cost savings and environmental sustainability.

11. User-Friendly Design: Ergonomic design aspects like adjustable heights, easy-to-load hoppers, and intuitive interfaces make the machine accessible for operators of varying skill levels.

12. Customizability: Optional features like multiple filling heads, different dosing systems, and custom software configurations to meet specific customer requirements.

In summary, a bag filling machine combines speed, accuracy, and durability, with advanced automated controls and safety features, designed for efficient, versatile, and reliable packaging in various industrial applications.

List Application of "bag filling machine"

Bag filling machines are pivotal in various industries due to their efficiency in packaging products in different types of bags. Here are some key applications:

1. Food Industry:

- Grains and Seeds: Efficiently package rice, wheat, seeds, and other grains.

- Snacks and Confectionery: Ideal for nuts, chips, candies, and chocolates.

- Powders and Spices: Package flour, baking powder, spices, and other such products.

- Pet Food: Suitable for dry dog and cat food.

2. Pharmaceuticals and Chemicals:

- Medicinal Powders: Ideal for powdered medications and supplements.

- Chemical Powders: Used for packaging fertilizers, pesticides, and other chemicals safely.

- Granules and Capsules: Efficient for granular chemicals and capsule packaging.

3. Agriculture:

- Fertilizers and Seeds: Bag filling machines are crucial for packaging fertilizers and seeds in various quantities.

- Feed: Essential for packing animal feed.

4. Construction and Building Materials:

- Cement and Sand: Used for packaging cement, sand, and other building materials.

- Gravel and Aggregate: Suitable for heavy-duty packaging of gravel and construction aggregates.

5. Consumer Goods:

- Household Products: Filling detergents, salt, sugar, and other household items.

- Garden Products: Packaging soil, mulch, and compost.

6. Industrial Applications:

- Lubricants and Greases: Packaging industrial lubricants and greases.

- Parts and Components: Bagging small mechanical parts and accessories.

7. Recycling and Waste Management:

- Recycled Materials: Packaging recycled plastics, metals, and other materials.

- Waste Products: Efficiently bagging agricultural and industrial waste.

In essence, bag filling machines bolster efficiency, enhance product safety, and ensure precise quantity control in packaging across diverse industries, thereby significantly improving operational workflows.

List Various Types of "bag filling machine"

Certainly! Here are various types of bag filling machines, each suited to different industries and applications:

-

Volumetric Fillers

- Cup Fillers: Measure bulk products like grains, rice, and seeds by volume.

- Auger Fillers: Use a rotating auger screw to dispense powdery or granulated materials such as flour, spices, and detergent. -

Gravimetric Fillers

- Net Weigh Fillers: Precisely measure and dispense the desired weight, suitable for products like nuts, cereal, and chemicals.

- Gross Weigh Fillers: Weigh the product directly into the bag, ideal for heavier, bulk materials. -

Vacuum Fillers

- Utilized mainly for sealing and preserving perishable products like coffee and certain pharmaceuticals, these create a vacuum environment to extend shelf life.

-

Pneumatic Fillers

- Use compressed air to fill bags quickly, ideal for lightweight or aerated materials such as foams and certain types of snacks.

-

Laminated Bag Fillers

- Specifically for products that come in laminated or multi-layer bags, used in food packaging, pet food, and some chemicals.

-

Form-Fill-Seal (FFS) Machines

- Vertical FFS: Vertically oriented, suitable for liquids, powders, and granules.

- Horizontal FFS: Used for products like pre-made pouches, offering robust packaging for more solid items like candies and bars. -

Flexible Intermediate Bulk Container (FIBC) Fillers

- Designed for very large bags, used in industry sectors like agriculture, construction, and raw materials processing.

-

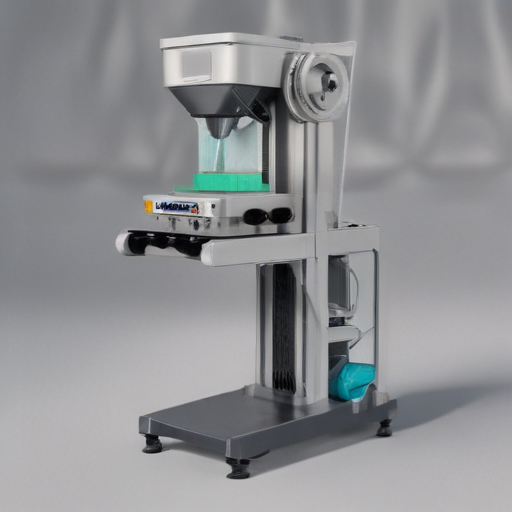

Semi-Automatic Fillers

- Require some manual intervention but provide flexibility for small batches and startups. Commonly used for a variety of granular and fine powder materials.

-

Automatic Fillers

- Fully automated, most efficient for high-volume production. Suitable for industries ranging from food & beverage to pharmaceuticals and chemicals.

Each type is designed to maximize efficiency and accuracy for specific products and industries. The choice of bag filling machine will depend on the type of product, the required speed, and accuracy of filling, as well as the level of automation desired.

Custom Manufacturing Options for bag filling machine

When selecting custom manufacturing options for a bag filling machine, several factors must be considered to ensure the equipment aligns with your specific operational needs. Key customizations include:

1. Filling Mechanisms:

- Gravity Fillers: Suitable for free-flowing products.

- Auger Fillers: Ideal for powdery substances.

- Pneumatic Fillers: Use air pressure for lightweight materials.

2. Bag Types:

- Open-Mouth Bags: Easy to fill and seal.

- Valve Bags: For rapid, dust-free filling.

- Flexible Intermediate Bulk Containers (FIBCs): For bulk items.

3. Material Handling:

- Manual Systems: Cost-effective for small-scale operations.

- Semi-Automatic Systems: Balancing cost and efficiency.

- Fully Automatic Systems: Optimal for high-volume production.

4. Sealing Options:

- Heat Sealing: Common for thermoplastic bags.

- Sewing: Used for fabric bags.

- Ultrasonic Sealing: Provides high strength seals for synthetic materials.

5. Integration with Existing Systems:

- Ensure compatibility with current production lines and packaging systems to streamline processes.

6. Weighing and Counting:

- Volumetric Fillers: For consistent volume.

- Gravimetric Fillers: For precise weight.

7. Additional Features:

- Dust Control Systems: Maintain a clean work environment.

- Barcode Scanners: For inventory management.

- User Interface Options: Touchscreen panels or IoT integration for better control and monitoring.

Customizing these elements can significantly improve productivity, accuracy, and efficiency. Consulting with a specialized manufacturer will help you design a tailored solution that meets your specific operational requirements.

List Quality Control and The Manufacturing Process of "bag filling machine"

Quality Control and Manufacturing Process of Bag Filling Machine

#### Manufacturing Process:

1. Design and Planning:

- Initial requirements and specifications are gathered.

- Engineers create CAD models and simulations to optimize the design.

2. Material Selection:

- High-quality stainless steel and other required materials are chosen for durability and hygiene.

3. Fabrication:

- Laser cutting and CNC machining shape the components.

- Welding and assembly of frames and critical parts are done in line with the design specifications.

4. Assembly:

- Component integration, including filling nozzles, conveyors, and sealing mechanisms.

- Electrical systems and PLC programming for automated controls.

5. Verification:

- Inspect individual components and sub-assemblies for alignment with design specifications.

#### Quality Control:

1. Incoming Material Inspection:

- Verify the quality and specifications of raw materials and components received from suppliers.

2. In-Process Quality Checks:

- Regular inspections during fabrication and assembly stages.

- Use of precision tools to ensure components meet tolerance requirements.

3. Functional Testing:

- Test the assembled machine for performance, accuracy, and consistency in filling bags.

- Conduct trial runs to calibrate and adjust mechanisms for optimal operation.

4. Electrical and Safety Checks:

- Verify the functionality of electrical components and control systems.

- Ensure compliance with safety standards and regulations.

5. Final Inspection:

- A comprehensive examination of the completed machine, including cosmetic and functional aspects.

- Certify the machine for quality assurance and readiness for dispatch.

6. Documentation and Training:

- Provide detailed manuals and training for operators.

- Ensure all quality control processes and results are documented.

By adhering to these quality control and manufacturing processes, the integrity, efficiency, and reliability of the bag filling machine are ensured.

How to use "bag filling machine"

A bag filling machine automates the process of filling various materials into bags. Here's a step-by-step guide on how to use one, keeping it under 300 words:

1. Read the Manual: Familiarize yourself with the specific machine model by reading the manufacturer’s instructions.

2. Setup:

- Position the Machine: Place it on a stable, flat surface.

- Power Connection: Plug the machine into a suitable power source.

- Material Loading: Load the hopper with the material to be filled. Ensure it's clean and unclogged.

3. Calibration:

- Set Bag Size: Adjust the machine to match the size of the bags you will be using.

- Weight Adjustment: Set the desired fill weight using the control panel or manual dials.

4. Bag Attachment:

- Align Bag: Place the bag under the filling nozzle or attach it if using a clamp-based system.

- Secure Bag: Ensure it’s properly aligned and secured to avoid spillage.

5. Operation:

- Start Machine: Turn on the machine using the start button or switch.

- Filling Process: The machine will automatically dispense the material into the bag until the preset weight is achieved.

- Automatic Stop: Most machines will stop once the bag is filled to the desired weight.

6. Bag Removal:

- Detach Bag: Carefully remove the filled bag from the nozzle or clamp.

- Seal Bag: Seal the bag using a heat sealer or other sealing method as required.

7. Repeat: Place a new bag and repeat the process for additional bags.

8. Maintenance:

- Clean Machine: Regularly clean the machine to prevent residue buildup.

- Routine Checks: Perform routine checks and maintenance as per the manufacturer’s guidelines to ensure longevity and proper function.

Safety Tips:

- Wear Protective Gear: Gloves, masks, and eye protection as needed.

- Emergency Stop: Know the location of the emergency stop button for quick shutdown.

By following these steps, you can efficiently use a bag filling machine while ensuring safety and accuracy.

List Properties and Terms of "bag filling machine"

A bag filling machine is an automated or semi-automated device designed to fill bags with a predetermined quantity of material. These machines are widely used in various industries, such as food, pharmaceuticals, chemicals, and construction, among others. Below are the key properties and terms associated with bag filling machines:

Properties:

1. Accuracy: The precision with which the machine can measure and fill the desired quantity into the bags.

2. Capacity: The volume or weight of material the machine can fill per cycle or hour.

3. Speed: The rate at which bags are filled, often measured in bags per minute (BPM).

4. Compatibility: The types of materials (powder, granules, liquids, etc.) the machine can handle.

5. Adjustability: The ease of changing settings for different bag sizes or quantities.

6. Durability: The lifespan and robustness of the machine under continuous operation.

7. Automation Level: The extent to which the machine requires human intervention vs. operates autonomously.

8. Ease of Cleaning: The ability to clean the machine, which is particularly important in hygiene-sensitive industries like food and pharmaceuticals.

9. Safety Features: Mechanisms to ensure operator safety and prevent accidents.

10. Energy Efficiency: The amount of energy required to operate the machine effectively.

11. Construction Material: The materials used in the construction of the machine, often stainless steel for hygiene purposes.

12. User Interface: The simplicity and intuitiveness of the controls and display for the operator.

Terms:

1. Hopper: The container that holds the material to be dispensed into the bags.

2. Weighing Mechanism: The system used to measure the material before filling, which could be load cells, volumetric systems, or gravimetric systems.

3. Conveyor System: The mechanism that moves the filled bags from one point to another.

4. Feeder: The part that regulates the flow of material from the hopper to the bag.

5. Sealing Mechanism: The system to seal the bags after filling, which could be heat sealing, ultrasonic sealing, or zipper locking.

6. Dust Control: Features to manage and minimize dust during the filling process.

7. Batching: The process of filling specific quantities for production runs.

8. PLC (Programmable Logic Controller): Used for automation, control, and monitoring of the filling process.

9. CIP (Clean-in-Place): A system that allows for automatic cleaning of interior surfaces without disassembly.

List The Evolution history of "bag filling machine"

The evolution of the bag filling machine traces its development through various technological phases, meeting industrial needs for efficient and accurate packaging.

1. Early Manual Methods: Initially, bag filling was done manually, a labor-intensive and time-consuming process. Workers would scoop or shovel materials into bags, which was efficient for small-scale operations but insufficient for large-scale production.

2. Mechanized Systems (Late 19th - Early 20th Century): The Industrial Revolution brought the first mechanized filling systems. Simple volumetric or gravimetric systems using basic mechanical components like levers and pulleys were introduced to improve speed and reduce labor.

3. Semi-Automatic Machines (Mid 20th Century): The mid-20th century saw the advent of semi-automatic bag filling machines. These utilized conveyor belts, electric motors, and rudimentary controls, allowing a single operator to oversee multiple filling stations, thereby increasing throughput.

4. Electronic Integration (Late 20th Century): Technological advancements permitted the integration of electronic controls, leading to more precise filling processes. Load cells for weight measurement and programmable logic controllers (PLCs) enhanced accuracy and efficiency.

5. Fully Automatic Systems (Late 20th - Early 21st Century): Automation became more prevalent with machines capable of performing several tasks — from material dosing and bag opening to sealing and labeling — without human intervention. Improved sensors, computerized control systems, and robotic elements marked this period.

6. Smart and Connected Machines (21st Century): The latest evolution includes Industry 4.0 technologies, enabling smart and connected systems. Real-time monitoring, IoT integration, data analytics, and machine learning improve operational efficiency, predictive maintenance, and customization. Additionally, modern machines ensure compliance with stricter safety and hygiene standards.

The bag filling machine has evolved from rudimentary manual operations to sophisticated automated systems, reflecting broader technological advancements and responding to the increasing demands for precision, efficiency, and scalability in various industries.

How to Select a Reliable bag filling machine

Selecting a reliable bag filling machine involves several key considerations:

1. Capacity and Speed: Assess your production requirements, including the required filling speed and volume. Ensure the machine can handle your specific workload efficiently.

2. Type of Material: Determine the type of material you will be filling, whether it's powder, granules, or liquids. Different machines are designed for different materials, so choose one that caters to your product type.

3. Accuracy and Precision: Look for machines that offer high accuracy and precision in filling to minimize waste and ensure consistent product quality.

4. Automation Level: Decide on the level of automation you need. Fully automated machines can increase productivity and reduce labor costs, but semi-automated ones may suffice for smaller operations.

5. Flexibility and Scalability: Choose a machine that can adapt to various bag sizes and types. Also, consider whether the machine can be scaled up to meet future growth.

6. Build Quality and Durability: Invest in machines made from high-quality materials like stainless steel for durability and hygiene. A reliable machine should withstand long-term use and harsh industrial environments.

7. Ease of Use and Maintenance: Opt for machines that are easy to operate and maintain. Simple and user-friendly interfaces can significantly reduce training time and operation errors.

8. Manufacturers and Support: Select a reputable manufacturer known for quality and reliable support services. Good after-sales service and easy availability of spare parts are crucial.

9. Compliance with Standards: Ensure the machine complies with relevant industry standards and certifications (e.g., ISO, CE) to avoid legal and safety issues.

10. Budget: Finally, balance your budget with the features and reliability of the machine. Sometimes, investing a little more upfront for a higher-quality machine can be more cost-effective in the long run.

By considering these factors, you can confidently choose a reliable bag filling machine that meets your needs.

List "bag filling machine" FAQ

Bag Filling Machine FAQ

1. What is a bag filling machine?

A bag filling machine is a type of industrial equipment used to fill bags with a specified quantity of materials like granules, powders, and liquids efficiently and accurately.

2. What types of materials can it handle?

These machines can handle a wide variety of materials including food products, chemicals, pharmaceuticals, construction materials, and agricultural goods.

3. What are the different types of bag filling machines?

There are several types including:

- Automatic Bag Filling Machines: Fully automated with minimal human intervention.

- Semi-Automatic Bag Filling Machines: Require some manual operation.

- Vertical Form Fill Seal (VFFS) Machines: Create bags from a flat roll of film.

- Volumetric Fillers: Dispense a specific volume of material into each bag.

- Weighing Fillers: Use scales to ensure each bag is filled to a specific weight.

4. How do you choose the right bag filling machine?

Consider factors like the type of material, desired speed of production, level of automation needed, and budget. Consulting with manufacturers can also help tailor solutions to specific needs.

5. What are the benefits of using a bag filling machine?

- Efficiency: Faster and more consistent filling compared to manual methods.

- Accuracy: Precise control over the amount of material dispensed.

- Reduced Labor: Minimizes manual intervention.

- Versatility: Capable of handling various types of materials and bag sizes.

6. What maintenance is required?

Regular maintenance includes:

- Cleaning: Especially for food-grade machines.

- Lubrication: For moving parts.

- Inspection: Periodic checking for wear and tear.

7. Are there safety features included?

Most modern machines come equipped with features like emergency stop buttons, safety guards, and alarms to ensure user safety.

8. Can they be integrated into existing production lines?

Yes, many bag filling machines can be integrated with other equipment like conveyors and palletizers for seamless production flow.

9. What are common problems and how are they resolved?

- Blockages: Typically resolved by cleaning and ensuring materials are properly processed.

- Inaccurate Filling: Calibration and regular maintenance generally rectify this issue.

10. Where can I get support and spare parts?

Top 10 FAQ with answer about bag filling machine for Buyer Sourcing from China

Certainly! Here are the top 10 FAQ with answers about sourcing a bag filling machine from China, specifically tailored for buyers:

-

What types of bag filling machines are available?

- There are various types, including manual, semi-automatic, and fully automatic machines. They cater to different bag types like pre-made bags, stand-up pouches, and sachets.

-

What is the typical lead time for manufacturing and delivery?

- Lead times vary by complexity and customization but typically range from 3-8 weeks. Shipping can add an additional 1-4 weeks.

-

How do I evaluate the quality of the machine?

- Review certifications (CE, ISO), request client references, and check testimonials. Visiting the factory and seeing a machine demo can also help.

-

Are machines customizable?

- Yes, most manufacturers offer customization to meet specific requirements like bag size, filling volume, and speed.

-

What is the average cost?

- Costs vary widely based on type and features. Expect anywhere from $5,000 to $50,000. Request detailed quotes for accurate pricing.

-

What are the payment terms?

- Common terms include T/T (Telegraphic Transfer), with a 30-50% deposit and the balance paid before shipping. L/C (Letter of Credit) is also an option.

-

What is the warranty period?

- Warranty periods usually range from 1 to 2 years. It typically covers parts and labor but check for specifics.

-

Is after-sales support available?

- Most reputable manufacturers offer after-sales support, including online troubleshooting, spare parts, and technician visits.

-

How do I handle import duties and customs?

- Usually, the buyer is responsible. Hiring a customs broker can streamline the process. Familiarize yourself with HS codes to estimate duties.

-

What should be included in the purchase contract?

- Include specifics on machine specs, delivery timeline, payment terms, warranty, after-sales support, and penalties for delays.

By addressing these FAQs, buyers can confidently navigate the process of sourcing a bag filling machine from China.