List Technical Parameters of "canada packaging machines"

Canada packaging machines, which include a broad range of equipment such as flow wrappers, bottling machines, carton sealers, and palletizers, encompass various technical parameters. These machines are used across industries like food and beverage, pharmaceuticals, cosmetics, and logistics. Below are some key technical parameters:

1. Throughput Capacity: Measures the number of units per minute or hour the machine can handle. This can vary from low-speed manual or semi-automated machines to high-speed automated systems processing thousands of units per hour.

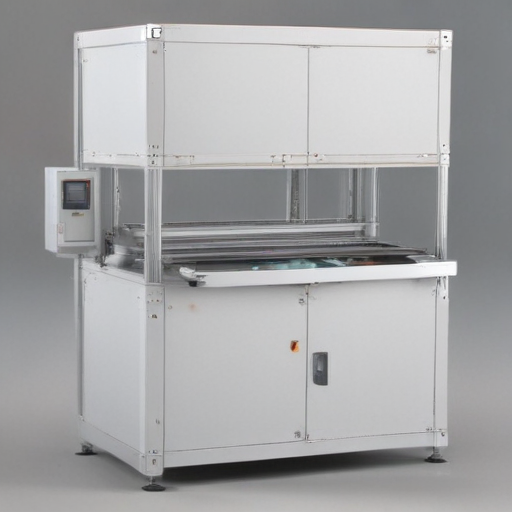

2. Packaging Type: Refers to the type of packaging the machine handles – bottles, boxes, pouches, cartons, etc. This includes specifics like size range, material compatibility (plastic, glass, cardboard), and sealing methods (heat seal, glue, etc.).

3. Machine Dimensions: Overall dimensions including height, width, length, and footprint. This is crucial for facility planning and ensuring the machine fits the production environment.

4. Power Requirements: Voltage, phase, and power consumption details (e.g., 220V single-phase or 480V three-phase).

5. Air Pressure Requirements: For machines that use pneumatic systems, required air pressure and consumption rates (e.g., 6 bar, 100 L/min).

6. Control System: Type of control systems used, typically PLCs (Programmable Logic Controllers) with HMI (Human-Machine Interface) for user interaction and recipe management.

7. Material Compatibility: Types of packaging materials compatible with the machine, such as polyethylene, polypropylene, paperboard, or biodegradable plastics.

8. Accuracy and Precision: Tolerances in measures like filling volume, weight, or dimensions, typically measured in grams or millimeters.

9. Operation Mode: Indicates whether the machine is manual, semi-automated, or fully automated.

10. Compliance and Certifications: Industry standards and certifications the machine meets, like CE marking, FDA requirements for food and pharma, or CSA standards for electrical equipment in Canada.

11. Maintenance Requirements: Information on maintenance frequency, type, and ease of access for servicing components.

By understanding these parameters, businesses can make informed decisions to align machine capabilities with production requirements and operational goals.

List Product features of "canada packaging machines"

Canada Packaging Machines, renowned for their high-quality packaging solutions, brings a range of product features designed to meet diverse industry needs. Here’s a concise overview of the key features:

1. Versatility: These machines are adaptable for various packaging types— from pouches and bottles to cartons and cans, suitable for industries like food & beverage, pharmaceuticals, cosmetics, and more.

2. Advanced Automation: Equipped with cutting-edge automation technology, they enhance productivity by reducing manual labor and increasing throughput.

3. Precision and Consistency: Precision engineering ensures consistent packaging, minimizing errors and maintaining product quality.

4. High-Speed Operations: Designed to operate at high speeds without compromising quality, allowing for efficient mass production.

5. User-Friendly Interface: Intuitive touch-screen interfaces enable easy operation, reducing training time and operator errors.

6. Durability and Reliability: Manufactured with robust materials and reliable components, these machines offer long-term durability and minimal downtime.

7. Energy Efficiency: Engineered to consume less power, these machines help lower operational costs and support sustainable practices.

8. Customizability: Tailored solutions are available to meet specific requirements, ensuring optimal performance for various packaging tasks.

9. Compact Design: Space-saving designs make these machines suitable even for facilities with limited floor space.

10. Hygienic Design: Utilizing stainless steel and other sanitary materials, they meet strict hygiene standards, crucial for food and pharmaceutical industries.

11. Integrated Safety Features: Safety mechanisms are in place to protect operators and maintain secure operations.

12. Easy Maintenance: Designed for straightforward cleaning and maintenance, reducing downtime and service costs.

13. Scalability: Flexibility to scale operations up or down based on demand, making them suitable for small businesses to large enterprises.

These features make Canada Packaging Machines a go-to solution for companies seeking efficiency, reliability, and high-quality packaging capabilities.

List Application of "canada packaging machines"

Canada packaging machines are used in a wide range of industries to enhance efficiency, maintain product quality, and ensure safety during the packaging process. Below are some key applications:

1. Food and Beverage Industry:

– Primary Packaging: Machines are used for packaging individual food items, such as chips, cereals, and beverages.

– Secondary Packaging: Packaging machines bundle products into larger units, like boxes or cases, for distribution.

– Shelf-Ready Packaging: Enabling easy shelf placement for retail purposes.

2. Pharmaceutical Industry:

– Blister Packaging: For tablets and capsules, ensuring precise dosing and protection from contamination.

– Bottle Filling: Liquid medicines are filled into bottles hygienically.

– Labeling Machines: Ensure compliance with regulatory standards by properly labeling products with essential information.

3. Cosmetics Industry:

– Tube Filling: For creams and lotions, maintaining product integrity.

– Cartoning: Secondary packaging for retail display, preserving aesthetics and providing information.

4. Automotive Industry:

– Parts Packaging: Ensures safe transport of various parts, reducing damage and loss.

– Kitting and Assembly: Pre-packaging kits for assemblies to streamline manufacturing processes.

5. Consumer Goods:

– Household Items: Packaging for items like detergents and cleaning supplies.

– Electronics: Packaging of electronic goods to protect from static and physical damage.

6. Agriculture:

– Seed and Fertilizer Packaging: Ensuring products are kept dry and secure.

– Pest Control: Safely packaging chemicals and sprays to prevent leaks and contamination.

7. Medical Devices:

– Sterile Packaging: Ensures equipment remains sterile until use.

– Custom Packaging Solutions: For specific devices that require unique packaging configurations.

These applications highlight the versatility and essential role of packaging machines in various Canadian industries, ensuring efficiency, safety, and regulatory compliance.

List Various Types of "canada packaging machines"

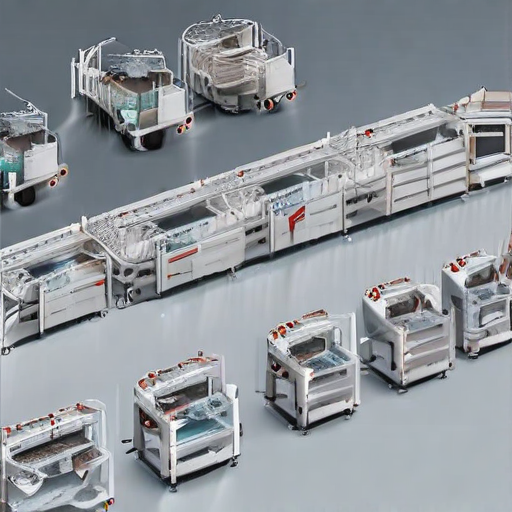

Canada is home to a wide array of packaging machinery manufacturers and suppliers, offering diverse solutions tailored to various industries. Here are some common types of packaging machines available in Canada:

1. Filling Machines:

– Liquid Filling Machines: Used for beverages, oils, and cleaning agents.

– Powder Filling Machines: For products like flour, spices, and detergent powders.

– Granule Filling Machines: Suitable for grains, seeds, and pellets.

2. Sealing Machines:

– Heat Sealers: For sealing thermoplastic materials using heat.

– Vacuum Sealers: Remove air before sealing, commonly used for food products.

– Induction Sealers: Uses electromagnetic induction to seal containers with a foil liner.

3. Labeling Machines:

– Automatic Labeling Machines: For high-speed, high-volume applications.

– Semi-Automatic Labelers: Suitable for smaller batches or specialty products.

– Print & Apply Labelers: Print labels on demand and apply them to the product.

4. Wrapping Machines:

– Shrink Wrap Machines: Encloses products in shrink film for protection.

– Stretch Wrap Machines: Used for palletizing and securing large loads during transportation.

– Flow Wrap Machines: For high-speed packaging of items like candy bars and cookies.

5. Cartoning Machines:

– Horizontal Cartoners: Ideal for packing bottles, tubes, and blister packs.

– Vertical Cartoners: Suitable for products that can be loaded vertically, like bags of snacks.

6. Case Packing Machines:

– Robotic Case Packers: Precision and flexibility for various packaging configurations.

– Drop Packers: Products are dropped into cases, commonly for rigid containers.

7. Palletizing Machines:

– Traditional Palletizers: Use layers and patterns for stacking.

– Robotic Palletizers: High flexibility and automation for various products.

8. Form, Fill, and Seal (FFS) Machines:

– Vertical FFS: For products like chips, grains, and snacks.

– Horizontal FFS: Ideal for products like pouches of liquids and solids.

From food and beverages to pharmaceuticals and cosmetics, the Canadian packaging machine industry offers robust solutions to meet diverse industrial needs.

Custom Manufacturing Options for canada packaging machines

Custom manufacturing options for packaging machines in Canada cater to a diverse range of industries, from food and beverages to pharmaceuticals and consumer goods. Below are some key options and considerations:

1. Customization for Product Type:

– Specific Packaging Needs: Machines can be tailored to handle different types of packaging materials such as flexible pouches, cartons, bottles, and more.

– Product-Specific Adjustments: For example, machines can be customized to package liquids, solids, powders, or fragile items efficiently.

2. Integration with Existing Systems:

– Compatibility: Ensuring that new machines can seamlessly integrate with existing production lines and software systems.

– Automation and AI: Incorporating advanced technologies for enhanced efficiency and data analytics.

3. Scalability and Capacity:

– Variable Speed Control: Machines can be customized to operate at varying speeds to match production demands.

– Expandable Features: Options to add more capabilities as production scales up.

4. Regulatory Compliance:

– Industry Standards: Custom machines are designed to meet specific industry regulations, such as Health Canada and FDA guidelines.

– Sanitary Design: For food and pharmaceutical industries, ensuring machines are built for easy cleaning and hygiene.

5. Energy Efficiency:

– Sustainable Options: Machines can be designed to minimize energy consumption and reduce environmental impact.

6. After-Sales Support:

– Training and Maintenance: Access to ongoing technical support, training for operators, and regular maintenance services.

– Spare Parts Availability: Ensuring long-term availability of custom parts.

7. Innovative Technologies:

– Smart Packaging Solutions: Incorporating features like QR code printing, RFID tags, and smart sensors.

– User-Friendly Interfaces: Touchscreens and remote monitoring capabilities for ease of operation.

By opting for a custom-designed packaging machine, Canadian businesses can enhance efficiency, ensure regulatory compliance, and meet unique production requirements, ultimately leading to better product quality and customer satisfaction.

List Quality Control and The Manufacturing Process of "canada packaging machines"

Quality Control in Canada Packaging Machines:

1. Raw Material Inspection: Rigorous quality checks on incoming materials to ensure they meet specified standards.

2. Component Testing: Thorough testing of individual parts to ensure functionality and durability.

3. In-Process Monitoring: Continuous monitoring during assembly to catch defects early, utilizing real-time data and automated inspection systems.

4. Calibration and Validation: Machines undergo regular calibration and validation to maintain accuracy and reliability.

5. Final Inspection: Comprehensive testing of fully assembled machines to verify performance against predefined criteria.

6. Certification and Compliance: Ensuring machines meet industry standards and regulations such as ISO, FDA, and others.

7. Customer Feedback Loop: Collecting and analyzing customer feedback for ongoing product improvement.

Manufacturing Process of Canada Packaging Machines:

1. Design and Engineering: Initial stage involves detailed design and engineering using CAD software. Prototyping may be carried out to test feasibility.

2. Material Sourcing: High-quality materials and components are sourced from reliable suppliers to ensure durability and performance.

3. Fabrication: Components are manufactured using advanced fabrication techniques such as CNC machining, laser cutting, and welding.

4. Assembly: Skilled technicians assemble the machine components, ensuring precision and accuracy.

5. Wiring and Integration: Electrical wiring and integration of control systems are done, preparing the machine for automation.

6. Programming: Software and control systems are programmed to meet specific packaging requirements. This includes setting up user interfaces and automation protocols.

7. Testing and Validation: Machines undergo rigorous testing to ensure they meet all operational requirements. This includes trials under various conditions to test efficiency and reliability.

8. Finishing: Post-assembly, machines may undergo finishing processes like painting or coating for durability and aesthetics.

9. Packaging and Shipment: Completed machines are securely packaged and shipped to customers, with detailed manuals and operational guides provided.

By maintaining stringent quality control measures and following a meticulous manufacturing process, Canada packaging machine manufacturers ensure the production of high-quality, reliable, and efficient packaging machinery.

How to use "canada packaging machines"

Canada packaging machines refer to equipment designed and manufactured in Canada for various packaging needs. Here’s a concise guide on how to use them:

1. Choose the Right Machine:

– Assess your product type: liquid, solid, powder, etc.

- Determine production capacity needs.

– Consider machine features: speed, automation level, flexibility.

2. Installation:

- Ensure the installation area meets machine specifications (space, ventilation, power supply).

- Follow manufacturer’s guidelines for setup and calibration.

- Seek professional assistance if necessary.

3. Operation:

- Train your operators on machine functions and safety protocols.

- Load packaging materials (films, boxes, bottles) as specified.

- Set parameters (quantity, size, weight) on the machine’s control panel.

- Perform a trial run and make adjustments to settings if required.

4. Maintenance:

- Regularly clean machine components to prevent contamination and ensure smooth operation.

- Check for wear and tear and replace worn-out parts as needed.

- Keep a log of maintenance activities and monitor machine performance.

5. Troubleshooting:

- Refer to the user manual for solutions to common issues.

- Contact customer support for persistent or complex problems.

6. Compliance:

- Ensure the machine and your packaging process comply with local regulations and standards.

Using Canada packaging machines involves careful selection, proper installation, thorough training, routine maintenance, and adherence to safety and compliance standards for optimal performance and product integrity.

List Properties and Terms of "canada packaging machines"

Properties and Terms of Canada Packaging Machines

-

Automation

– Fully Automated: Machines with minimal human intervention.

– Semi-Automated: Requires partial human interaction. -

Technology

– PLC (Programmable Logic Controllers): Enhances precision and efficiency.

– AI Integration: For smarter, adaptive operations.

– IoT Connectivity: Ensures real-time monitoring and data analytics. -

Types

– Filling Machines: For liquids, powders, and granules.

– Sealing Machines: Heat sealers, vacuum sealers.

– Labeling Machines: Pressure-sensitive, shrink sleeve, glue-based.

– Wrapping Machines: Stretch wrappers, shrink wrappers.

– Cartoning Machines: Horizontal and vertical cartoners.

– Form Fill Seal (FFS) Machines: For versatile packaging solutions. -

Materials Supported

– Flexible Packaging: Plastic films, foils.

– Rigid Packaging: Bottles, cans, jars.

– Eco-Friendly Materials: Biodegradable plastics, paper-based materials. -

Industries

– Food and Beverage: Ensures hygiene and freshness.

– Pharmaceuticals: Focus on precision and contamination prevention.

– Cosmetics: Aesthetic packaging solutions.

– Automotive: For parts and components packaging. -

Compliance and Standards

– CSA (Canadian Standards Association): Ensures safety compliance.

– FDA and CFIA Compliance: For food and pharmaceutical packaging.

– ISO Standards: Quality and environmental standards compliance. -

Customization Capabilities

– Adaptability: Custom solutions for specific needs.

– Scalability: From small businesses to large scale production. -

Efficiency Metrics

– Speed: Packaging rate (units per minute).

– Accuracy: Precision in filling and labeling.

– Energy Efficiency: Lower power consumption models. -

Maintenance and Support

– After-Sales Service: Technical support and training.

– Spare Parts Availability: Fast replacement parts service. -

Cost Considerations

– CAPEX: Initial investment costs.

– OPEX: Operational expenditures including maintenance.

List The Evolution history of "canada packaging machines"

The evolution of Canada packaging machines reflects significant advancements influenced by industrial needs, technological progress, and market demands. Here’s a concise history:

Early 20th Century:

Canada’s packaging industry began modestly with manual and semi-automated machines. These early machines focused on basic functions like sealing and labeling to aid in small-scale production.

Mid-20th Century:

Post-World War II, the Canadian economy grew, prompting industrialization. Packaging machines evolved to include more automated processes, such as conveyor belts and mechanized fillers, enhancing production efficiency. The introduction of plastic materials revolutionized packaging, leading to the development of machines capable of handling these new materials.

1970s-1980s:

With the rise of consumerism, packaging diversity increased. Canadian companies started adopting more specialized packaging machines, such as vacuum sealers and thermoformers. Automation became more sophisticated with programmable logic controllers (PLCs), improving reliability and precision.

1990s:

Technological advancements, especially in electronics and software, led to smarter packaging machines. Computer-integrated manufacturing (CIM) systems started to be used, enabling better control, monitoring, and integration with other production processes. Environmental concerns also began to shape the industry, promoting the development of machines designed to handle recyclable and biodegradable materials.

Early 2000s:

The focus shifted towards improving efficiency and reducing labor costs. Robotics and advanced sensor technologies were integrated into packaging lines, offering greater flexibility and speed. Sustainable practices became more prevalent, influencing machine design towards reducing waste and energy use.

2010s-Present:

The advent of Industry 4.0 brought digitalization to the forefront. Canadian packaging machines now feature IoT connectivity for real-time monitoring and predictive maintenance. Artificial intelligence and machine learning are being employed to optimize packaging operations. The push for sustainability has led to innovations in packaging materials and processes, with machines now being equipped to handle environmentally friendly packaging options.

The trajectory of Canada’s packaging machine evolution showcases continuous improvement driven by technological advancements and a growing emphasis on sustainability and efficiency.

How to Select a Reliable canada packaging machines

Selecting a reliable packaging machine in Canada requires careful consideration of several factors to ensure efficiency, quality, and longevity. Here’s a concise guide to help you make an informed choice:

1. Assess Your Needs: Clearly define the type of packaging you require, including the product size, shape, material, and production speed. Knowing your specific needs helps narrow down appropriate machine types, be it for filling, sealing, labeling, or cartoning.

2. Research Reputable Manufacturers: Look for established manufacturers with a strong presence in Canada. Companies like Premier Tech, WeighPack Systems, and Canadian Packaging stand out for their industry reputation.

3. Check for Customization and Flexibility: Select a machine that can be customized to your product specifications. A flexible machine that allows for adjustments as your business grows or evolves can be a smart investment.

4. Evaluate Technology and Features: Modern packaging machines come with advanced features such as automation, integration capabilities with existing systems, and user-friendly interfaces. Evaluate the technological advancements and choose a machine with the features that align with your production needs.

5. Consider Quality and Durability: Reliability is paramount in packaging machinery. Opt for machines constructed with high-quality materials and robust engineering. Check for industry certifications and standards compliance.

6. Customer Support and Service: Ensure the manufacturer offers excellent customer service, including installation, training, and maintenance support. After-sales service is crucial for troubleshooting and keeping the machine running smoothly.

7. Read Reviews and Testimonials: Look for customer reviews and testimonials to gauge real-world performance and reliability. Forums, industry publications, and case studies can provide valuable insights.

8. Cost and ROI: While cost is a major factor, focus on the long-term return on investment. A more expensive machine with lower operational costs and higher efficiency might be more cost-effective in the long run.

By evaluating these aspects, you can select a reliable packaging machine that aligns with your business goals and ensures consistent, high-quality packaging.

List "canada packaging machines" FAQ

Canada Packaging Machines FAQ

-

What types of packaging machines are available in Canada?

- Canada offers a wide range of packaging machines, including filling machines, sealing machines, labeling machines, shrink wrapping machines, and palletizing systems.

-

Are Canadian packaging machines suitable for different industries?

- Yes, these machines cater to various industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and logistics.

-

Where can I buy packaging machines in Canada?

- Packaging machines can be purchased from specialized equipment suppliers, online marketplaces, and directly from manufacturers. Some well-known Canadian suppliers include Tech-Long Canada, WeighPack Systems, and Paxiom Group.

-

Do Canadian packaging machine suppliers offer customization?

- Many suppliers provide custom solutions tailored to specific production needs. Customization options can include machine dimensions, speed, and specialized features for unique packaging requirements.

-

What is the typical lead time for delivery?

- Lead times vary depending on whether the machine is in stock, customized, or requires importing. Standard machines can take a few weeks, while customized solutions may take several months.

-

Are there any after-sales services available?

- Many suppliers offer after-sales services including installation, training, maintenance, and technical support to ensure optimal machine performance.

-

How do I determine the right packaging machine for my needs?

- Assess your production volume, packaging type, budget, and specific industry requirements. Consulting with suppliers and considering future scalability can also guide decision-making.

-

What is the average cost of packaging machines in Canada?

- Costs can range from a few thousand to several hundred thousand dollars, depending on the machine type, complexity, and customization.

-

Is financing available for purchasing these machines?

- Yes, various financing options, such as leasing, loans, and payment plans, are commonly provided by suppliers and financial institutions.

-

Are Canadian packaging machines compliant with international standards?

- Many Canadian-made machines comply with global standards like ISO, CE, and GMP, ensuring quality and safety for international markets.

By providing comprehensive solutions and services, the Canadian packaging machine industry supports an array of packaging needs across diverse sectors.

Top 10 FAQ with answer about canada packaging machines for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) with answers about sourcing packaging machines from China for the Canadian market:

-

What are the benefits of sourcing packaging machines from China?

Answer: Sourcing from China often offers cost advantages, access to a wide variety of suppliers, and the potential for scalable production capabilities with advanced technology. -

What certifications should packaging machines have for use in Canada?

Answer: Packaging machines should have CSA (Canadian Standards Association) certification and compliance with Health Canada’s safety regulations. CE and ISO certifications can also be beneficial. -

How can I verify the reliability of a Chinese supplier?

Answer: Verify the supplier’s credentials by checking their business license, certifications, and client references. Using platforms like Alibaba or Made-in-China can also help in evaluating supplier ratings and reviews. -

What types of packaging machines are commonly sourced from China?

Answer: Common machines include automatic filling, sealing, labeling, shrink-wrapping, and vacuum packaging machines. Custom solutions are also available based on requirements. -

How can I ensure the quality of the machines before purchasing?

Answer: Request samples, visit the supplier’s factory, or hire a third-party inspection service. Ensure the machines undergo quality assurance and testing as per your specifications. -

What is the typical lead time for receiving packaging machines from China?

Answer: Lead times can vary but typically range from 30 to 90 days, depending on the complexity of the machine and the supplier’s production schedule. -

What is the average shipping cost for packaging machines to Canada?

Answer: Shipping costs depend on the machine’s size, weight, and shipping method. On average, expect to pay between USD 500 to USD 5000 for ocean freight. -

Are there any import duties or taxes applicable for importing machines from China?

Answer: Yes, import duties and taxes apply. Import duties vary; typically between 0-10%. Additionally, there’s GST (Goods and Services Tax) applicable. -

How do I handle after-sales service and maintenance for Chinese machines in Canada?

Answer: Confirm if the supplier offers after-sales support and training. Establish a service agreement and ensure that technical support is available remotely or through local partners. -

Can I customize packaging machines to meet specific product needs?

Answer: Yes, customization is usually possible. Provide detailed specifications to the supplier, and they can tailor the machine to match specific product and packaging requirements.