List Technical Parameters of "cannabis packaging machines"

Technical parameters for cannabis packaging machines can vary based on the specific type and brand, but generally include the following:

1. Packaging Speed: Ranges from 10 to 100+ bags/pouches per minute, depending on the machine's capacity and automation level.

2. Accuracy: Precision in weighing and filling, typically around ±0.01 grams, crucial for compliance with regulations.

3. Pouch/Bag Size: Capability to handle various pouch sizes, commonly from 2 grams up to several pounds.

4. Film Material Compatibility: Machines should be compatible with various film materials like polyethylene, polypropylene, and eco-friendly films.

5. Sealing Type: Includes options like heat sealing, ultrasonic sealing, or vacuum sealing depending on the required shelf life and product type.

6. Automation Level: Ranges from semi-automatic to fully automatic solutions, with fully automatic systems integrating filling, weighing, sealing, and labeling.

7. Control System: Advanced PLC (Programmable Logic Controller) systems with touchscreens for easy operation and adjustments.

8. Integration Capabilities: Ability to integrate with other systems like labeling machines, checkweighers, and metal detectors.

9. Material Construction: Typically stainless steel, ensuring compliance with hygiene standards and durability.

10. Power Supply: Commonly operates on 220V or 380V, with varying power consumption based on the machine's size and capabilities.

11. Compressed Air Requirement: Some machines need a specific air pressure for operations like vacuum sealing, usually around 0.6 MPa.

12. Dimensions and Weight: Varies based on model and function but needs to fit within the production space allocated.

13. Software and Connectivity: Includes remote monitoring, data logging, and troubleshooting capabilities, often via Ethernet or Wi-Fi.

14. Safety Features: Emergency stop buttons, safety guards, and compliance with international safety standards.

These parameters are essential to ensure the machine meets the specific needs of cannabis product packaging, maintains regulatory compliance, and ensures product quality and efficiency.

List Product features of "cannabis packaging machines"

Cannabis packaging machines are specialized devices designed to facilitate the packaging process of cannabis products efficiently and accurately. Here's a list of their key product features:

1. Automated Operation:

- Speed & Efficiency: High-speed operation ensures rapid packaging, reducing labor costs.

- Consistency: Ensures uniformity in every package, enhancing product quality.

2. Versatility:

- Multiple Formats: Capable of handling various packaging formats like jars, bags, tubes, cartons, and blister packs.

- Flexible Adaptation: Easily adjustable to accommodate different product sizes and weights.

3. Precision & Accuracy:

- Exact Weighing: Advanced weighing systems provide precise weight measurements to meet regulatory standards.

- Minimized Waste: Reduces product waste through accurate dispensing and sealing.

4. User-friendly Interface:

- Touchscreen Control: Intuitive user interface for easy operation and monitoring.

- Programmable Settings: Customizable for different packaging needs, with the ability to store multiple programs.

5. Compliance & Safety:

- Child-Resistant Packaging: Ensures compliance with safety regulations.

- Tamper-evident Seals: Provides security features to indicate tampering.

6. Durable Construction:

- High-Quality Materials: Made from robust materials like stainless steel to withstand rigorous use.

- Hygienic Design: Easy to clean and maintain, ensuring product safety and hygiene.

7. Integration Capabilities:

- Connectivity: Compatible with other cannabis processing machinery for a seamless production line.

- Data Management: Ability to track and log packaging data for quality control and reporting.

8. Environmental Consideration:

- Eco-friendly Options: Availability of biodegradable and recyclable packaging materials.

9. Support & Service:

- Warranty: Comes with varying warranty periods for parts and labor.

- Technical Support: Includes access to customer service for troubleshooting and maintenance.

These features make cannabis packaging machines essential for companies looking to optimize their packaging process, ensuring efficiency, compliance, and quality.

List Application of "cannabis packaging machines"

Cannabis packaging machines, specifically designed to handle the unique requirements of the cannabis industry, serve multiple applications, greatly enhancing the efficiency and consistency of cannabis product packaging processes. Here are some primary applications:

1. Pre-Roll Packaging: These machines can efficiently fill, twist, and label pre-rolls, ensuring uniformity in product size and weight, which is crucial for customer satisfaction and regulatory compliance.

2. Flower Packaging: Machines automate the weighing, filling, and sealing of cannabis flowers in various packaging formats such as bags, jars, and containers, enhancing speed and reducing labor costs.

3. Edibles Packaging: These machines package cannabis-infused edibles like gummies, chocolates, and beverages. They ensure precise dosing and sanitary packaging, which are critical for edible products.

4. Concentrate Packaging: Cannabis packaging machines handle concentrates such as waxes, oils, and shatters, efficiently filling and sealing them in dab jars, syringes, or other containers, maintaining the integrity and potency of the product.

5. Blister/Capsule Packaging: These machines package cannabis tablets or capsules, ensuring precise dosing and tamper-evident packaging, which is essential for medical and nutraceutical applications.

6. Labeling and Coding: Automated systems for applying labels, batch numbers, and expiration dates guarantee compliance with regulatory requirements and enhance traceability throughout the supply chain.

7. Tamper-Evident Sealing: Machines provide tamper-evident solutions, such as shrink bands or induction seals, ensuring product safety and consumer trust.

8. Multi-Packaging and Bundling: For promotional purposes or bulk sales, machines can combine multiple units into single packages, improving logistics and storage efficiency.

In summary, cannabis packaging machines streamline the packaging process for various cannabis products, ensuring accuracy, compliance, and high production efficiency, which are vital for operating in the competitive and heavily regulated cannabis industry.

List Various Types of "cannabis packaging machines"

Certainly! Here are various types of cannabis packaging machines:

1. Pre-Roll Machines: These machines automate the process of filling and rolling pre-rolled joints. They ensure uniformity in size and tightness, often incorporating features like cone filling, twisting, and compacting.

2. Flower Packaging Machines: Used for packing dried cannabis flowers into bags, jars, or pouches. They often include features like weighing systems, bagging, sealing, and labeling to maintain product freshness and compliance.

3. Tincture and Oil Filling Machines: Designed for filling bottles or containers with cannabis oils, tinctures, or other liquid forms. These machines typically handle precise liquid measurements, capping, and sometimes labeling.

4. Edible Packaging Machines: These machines are intended for packaging cannabis-infused edibles like gummies, chocolates, and baked goods. They often include features for individual wrapping, sealing, and labeling to ensure dosage consistency and safety.

5. Vape Cartridge Filling Machines: Used to fill vape cartridges with cannabis oil. They focus on accuracy to prevent leakage and ensure uniformity. Some advanced models also include capping and labeling functionalities.

6. Packaging Automation Systems: Comprehensive systems that integrate multiple machines for tasks like filling, sealing, labeling, and quality checks. These are ideal for large-scale operations seeking streamlined packaging processes.

7. Bulk Packaging Machines: For wholesale distribution, these machines package large quantities of cannabis products into bulk containers. They often include features for weighing and sealing to ensure product integrity during transport.

8. Shrink Wrap Machines: Used for additional security and tamper-evidence, these machines shrink-wrap cannabis products in transparent film. This is particularly useful for multi-pack items.

9. Barrier Bag Filling Machines: Specialized for filling barrier bags that protect cannabis products from light, moisture, and air. These machines ensure the extended shelf life of the product.

10. Labeling Machines: Standalone machines focused solely on applying labels to various cannabis product packages, ensuring compliance with regulatory requirements.

Each type of machine is designed to optimize different facets of the packaging process, ensuring efficiency, compliance, and product integrity.

Custom Manufacturing Options for cannabis packaging machines

Custom manufacturing options for cannabis packaging machines cater to the specific needs of cultivators, processors, and dispensaries, ensuring compliance, efficiency, and brand differentiation. Here are key customization aspects:

1. Machine Types:

- Filling Machines: Customizable for different product types, including flowers, oils, edibles, and pre-rolls.

- Sealing Machines: Options for heat sealing, ultrasonic sealing, and vacuum sealing to maintain product freshness.

2. Capacity and Speed:

- Tailor capacity to match production volume, from small-batch to large-scale operations.

- Adjustable speeds to accommodate different production rates and ensure consistent output.

3. Packaging Formats:

- Customizable to handle diverse packaging types: jars, pouches, blister packs, tubes, and cans.

- Adjustment features for various packaging sizes and materials.

4. Automation Levels:

- Options range from semi-automatic to fully automated systems with robotic integration.

- Customizable automation for tasks like weighing, filling, capping, labeling, and cartoning.

5. Compliance Features:

- Incorporate tamper-evident and child-resistant features as per regulatory requirements.

- Ensure proper labeling with mandated information, like THC content and origin.

6. Integrated Software:

- Custom software for tracking and tracing, inventory management, and production analytics.

- User-friendly interfaces with customizable reporting tools.

7. Material Handling:

- Customizable conveyors, hoppers, and feeders for efficient material movement.

- Anti-static and anti-contamination features for sensitive products.

8. Branding and Design:

- Incorporation of custom graphics and packaging designs to enhance brand identity.

- Options for bespoke labeling and printing machinery to support unique branding needs.

Selecting the right custom solutions not only streamlines operations but also ensures compliance and boosts brand presence in the competitive cannabis market.

List Quality Control and The Manufacturing Process of "cannabis packaging machines"

Quality Control in Cannabis Packaging Machines

1. Compliance Checks:

Ensuring all machinery meets industry standards and regulatory requirements, including safety, hygiene, and environmental compliance specific to cannabis products.

2. Component Inspection:

Thorough evaluation of all machine components (motors, belts, electronic systems, etc.) for defects, alignment, and performance either through visual inspection or automated systems.

3. Functional Testing:

Machines undergo rigorous testing cycles to verify functionalities like precision filling, sealing, labeling, and coding of cannabis products.

4. Calibration:

Precision instruments within the machines are calibrated to ensure accurate dosing and packaging, conforming to specified tolerances.

5. Performance Monitoring:

Continuous monitoring for machine uptime and operational efficiency using performance data analytics to identify any anomalies and facilitate timely maintenance.

6. Sample Testing:

Regular sampling of the packaging output to verify that it meets quality standards in terms of weight, seal integrity, labeling accuracy, and overall presentation.

7. Documentation:

Maintaining detailed records of quality control processes, test results, and corrective actions to ensure traceability and compliance with regulatory requirements.

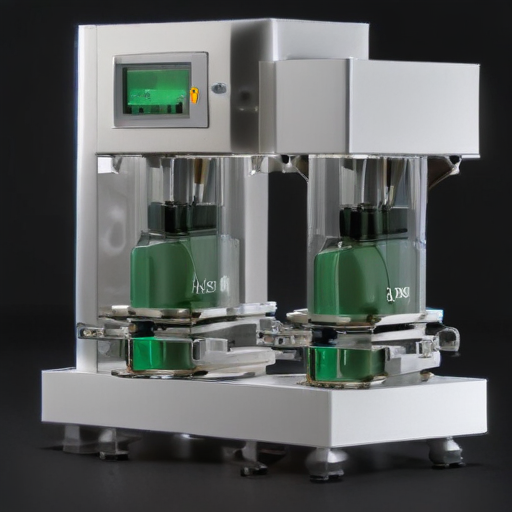

Manufacturing Process of Cannabis Packaging Machines

1. Design & Prototyping:

Engineers create detailed designs and 3D models, followed by the development of a prototype to validate the design, functionality, and ergonomics.

2. Material Selection:

High-quality, durable materials are selected based on requirements like corrosion resistance, food-grade compliance, and durability.

3. Component Manufacturing:

Using CNC machining, laser cutting, and other state-of-the-art manufacturing techniques to precisely fabricate machine parts.

4. Assembly:

Skilled technicians assemble components into functional units, ensuring precise alignment and adherence to assembly specifications.

5. Wiring & Integration:

Installation of electrical systems, sensors, and automation components with meticulous attention to detail to ensure safety and functionality.

6. Software Installation:

Integration of sophisticated software for operational control, diagnostic monitoring, and performance optimization of the packaging machines.

7. Final Testing:

Comprehensive testing of assembled machines under actual operating conditions to ensure optimal performance and reliability.

8. Packaging & Shipping:

Machines are securely packaged, often with custom crates, and shipped to clients with detailed instruction manuals and support documentation.

By adhering to rigorous quality control measures and a systematic manufacturing process, cannabis packaging machines are produced to deliver high performance and reliability.

How to use "cannabis packaging machines"

Using cannabis packaging machines efficiently involves several key steps to ensure compliance with regulations and maintain product quality. Here’s a concise guide:

1. Setup and Calibration:

- Read the Manual: Familiarize yourself with the machine’s manual for specific instructions.

- Calibration: Adjust the machine settings for weight, size, and type of cannabis product (flowers, edibles, oils).

- Safety Checks: Ensure all safety features are functional to prevent accidents.

2. Preparation:

- Select Packaging Material: Choose appropriate packaging (bags, jars, vials) designed to keep the cannabis fresh and compliant with regulations.

- Load Product: Fill the machine hopper with the cannabis product, ensuring it’s free of contaminants.

3. Operation:

- Power On: Switch on the machine and input the necessary parameters (weight, count, label type).

- Initiate Packaging: Start the machine. It will automatically measure, fill, and seal the packaging.

- Monitoring: Continuously monitor the process to ensure accuracy and troubleshoot any issues immediately.

4. Quality Control:

- Verify Packages: Randomly check the weight and seal of the packages to ensure they meet quality standards.

- Adjust Settings: Make necessary adjustments to the machine if discrepancies are found.

5. Maintenance:

- Clean Regularly: Clean the machine after each use to prevent residue buildup and product contamination.

- Routine Maintenance: Follow the maintenance schedule for parts replacement and lubrication.

6. Compliance:

- Labeling: Ensure all packages are correctly labeled with strain information, weight, and regulatory compliance labels.

- Documentation: Maintain records of the packaging process for quality assurance and regulatory audits.

By adhering to these steps, you can operate cannabis packaging machines effectively, ensuring efficiency and regulatory compliance simultaneously.

List Properties and Terms of "cannabis packaging machines"

Cannabis packaging machines are specialized devices designed for automating the packaging of cannabis products, such as flowers, edibles, extracts, and pre-rolls. They enhance efficiency, ensure compliance with regulatory standards, and maintain product quality. Here are some key properties and terms related to cannabis packaging machines:

Properties:

1. Automation:

- Levels: Semi-automatic, Fully Automatic

- Functionality: Reduces manual labor and increases throughput

2. Accuracy and Precision:

- Weighing: Accurate weight measurement to ensure consistency

- Filling: Precise filling to avoid over or underfill

3. Scalability:

- Capacity: Capable of handling small to large batch sizes

- Modular Design: Easily upgradable components

4. Compliance:

- Regulatory Adherence: Meets packaging, labeling, and safety standards

- Child-Resistant Features: Ensures product safety

5. Material Compatibility:

- Versatility: Compatible with various packaging materials (e.g., glass, plastic, pouches)

Terms:

1. Filling Systems:

- Volumetric Fillers: Dispenses product based on volume

- Weigh Fillers: Uses weight to dispense precise amounts

2. Labeling:

- Print and Apply: Direct printing of labels onto packages

- Thermal Transfer: High-quality, durable labels

3. Sealing:

- Heat Sealing: Secures pouches or bags using heat

- Vacuum Sealing: Removes air to preserve freshness

4. Capping:

- Automated Capping: Precisely places and secures caps on bottles or jars

5. Sorting and Counting:

- Pre-Roll Counters: Automates the counting and packaging of pre-rolled joints

6. Tamper-Evident Features:

- Shrink Bands: Applied to caps for tamper-evidence

- Security Seals: Ensures integrity of the package

Overall, cannabis packaging machines streamline the packaging process, improve accuracy, and ensure compliance with industry standards, making them indispensable in the cannabis industry.

List The Evolution history of "cannabis packaging machines"

The evolution of cannabis packaging machines mirrors technological and regulatory advancements over the years.

Early Manual Methods

- Pre-Legalization (before 1990s): Cannabis was often packaged manually in plastic bags or basic containers. The focus was primarily on concealment rather than efficiency or quality.

Initial Automation

- 1990s - Early 2000s: As marijuana legalization began to gain traction in certain areas, rudimentary machines designed for food or pharmaceutical packaging were adapted for cannabis. These included basic weigh and fill machines, sealing devices, and manual labeling systems.

Industry-Specific Machines

- 2010-2015: Following increased legalization and demand, cannabis-specific packaging machines emerged. Automated weigh-filling machines were developed to ensure precise dosing. Vacuum sealing and child-resistant packaging options also started to become standard.

Advanced Automation and Compliance

- 2015-2020: Significant technological advancements led to more sophisticated machines capable of handling various product forms, including buds, pre-rolls, edibles, and concentrates. These machines integrated advanced features such as:

- Precision Weighing: Ensuring compliant dosage.

- RFID and Barcode Integrations: For tracking and inventory management.

- Child-Resistant and Tamper-Evident Features: Meeting stringent regulatory requirements.

The Current Landscape

- 2020-Present: Modern cannabis packaging machines are highly specialized and automated. They include robotics for handling, machine learning for quality control, and IoT connectivity for real-time monitoring. The machines cater to diverse packaging needs—from flower buds to vape cartridges, offering eco-friendly options that appeal to environmentally-conscious consumers. Notable innovations include:

- Smart Packaging: Integrating QR codes for product information and authenticity verification.

- Sustainable Materials: Biodegradable and recyclable packaging options.

As cannabis legalization continues to expand, the packaging machinery sector is likely to witness further innovations aimed at improving efficiency, compliance, and sustainability.

How to Select a Reliable cannabis packaging machines

Selecting a reliable cannabis packaging machine is crucial for ensuring product quality, compliance, and operational efficiency. Here are key factors to consider:

1. Compliance and Certification:

Ensure the machine meets all regulatory requirements for cannabis packaging in your region. Look for machines that are cGMP (current Good Manufacturing Practice) certified to ensure they adhere to quality standards.

2. Machine Type and Versatility:

Identify the specific needs of your operation (e.g., flower, edibles, oils). Choose a machine that can handle your product type and offers versatility for future product lines.

3. Precise Dosing and Accuracy:

Accuracy is critical in cannabis packaging. Look for machines with precise dosing and minimal weight variance to comply with legal requirements and maintain product consistency.

4. Capacity and Scalability:

Match the machine’s capacity with your production volume. Consider machines that can easily scale up as your production grows to avoid future bottlenecks.

5. Build Quality and Reliability:

Invest in a machine from a reputable manufacturer known for high-quality construction and durability. Read reviews and ask for testimonials from other cannabis businesses.

6. User-Friendly Interface:

A machine with an intuitive interface reduces training time and increases operational efficiency. Features like touchscreens and programmable settings can enhance ease of use.

7. Service and Support:

Choose a supplier that offers robust after-sales support, including maintenance, training, and spare parts availability. This ensures minimal downtime and long-term reliability.

8. Customization Options:

Given the unique requirements of cannabis products, customized machines tailored to your specific needs might be beneficial. Ensure the supplier offers customization options.

9. Cost and ROI:

While cost is a factor, consider the machine's long-term ROI. A reliable, efficient machine may have a higher upfront cost but will save money in reduced downtime and higher throughput.

By focusing on these essential factors, you can select a reliable cannabis packaging machine that ensures quality, compliance, and operational efficiency.

List "cannabis packaging machines" FAQ

Cannabis Packaging Machines FAQ

-

What are cannabis packaging machines?

Cannabis packaging machines are specialized equipment designed to handle the automated packaging of cannabis products, ensuring efficiency, consistency, and compliance with regulatory standards. -

Why is automated packaging important in the cannabis industry?

Automated packaging ensures precision, improves speed, maintains product quality, and helps in adhering to strict legal packaging requirements, thereby reducing labor costs and human error. -

What types of cannabis products can be packaged using these machines?

These machines can handle a variety of forms including dried flowers, pre-rolls, edibles, oils, tinctures, and concentrates. -

What are common types of cannabis packaging machines?

Common types include:

- Weighing and filling machines: For precise dosing.

- Sealers: For securing packages.

- Labeling machines: For compliance and branding.

- Cartoners: For boxing individual units.

- Shrink wrap machines: For tamper-evident seals. -

How do weighing and filling machines work?

These machines use scales and sensors to accurately dispense predefined quantities of cannabis product into containers or bags, ensuring uniformity and compliance with weight regulations. -

What materials can cannabis packaging machines handle?

Machines can handle various packaging materials, including plastic, glass, mylar bags, cartons, and child-resistant containers. -

Are these machines customizable?

Yes, many manufacturers offer customizable options to accommodate different product sizes, shapes, and specific packaging requirements. -

How do these machines ensure compliance with regulations?

They incorporate features such as child-resistant closures, tamper-evident seals, accurate labeling, and can be programmed to meet specific state or national packaging laws. -

What factors should be considered when choosing a cannabis packaging machine?

Consider production volume, product type, compliance requirements, budget, and the level of automation needed. -

What is the typical cost of cannabis packaging machines?

Costs vary widely depending on the machine’s complexity, ranging from a few thousand dollars for simple machines to over $100,000 for high-end, fully automated systems.

By automating the packaging process, cannabis businesses can enhance operational efficiency, ensure compliance, and maintain product integrity, crucial for success in this competitive and regulated industry.

Top 10 FAQ with answer about cannabis packaging machines for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQ) about cannabis packaging machines for buyers sourcing from China:

-

What types of cannabis packaging machines are available?

- There are several types, including automatic pre-roll machines, flower packaging machines, oil cartridge fillers, edibles packaging machines, and labeling machines.

-

Are Chinese cannabis packaging machines compliant with international standards?

- Many reputable manufacturers adhere to international standards such as CE, ISO, and GMP. Always verify certifications before purchasing.

-

How is the quality of cannabis packaging machines from China?

- The quality can vary. It's essential to research manufacturers, check reviews, ask for references, and possibly request product samples or visit the factory if possible.

-

What is the typical lead time for cannabis packaging machines from China?

- Lead times can range from 4 to 12 weeks, depending on the complexity of the machine and the manufacturer’s production schedule.

-

Is there customer support and training available?

- Reputable companies often provide customer support, including installation and operator training either on-site or remotely. Verify the availability of these services.

-

What are the payment terms for purchasing from China?

- Common payment terms include a 30% deposit with the balance paid before shipment. Letters of Credit (LC) and trade assurance services on platforms like Alibaba are also options to ensure security.

-

Can I customize packaging machines to fit specific requirements?

- Many Chinese manufacturers offer customization options. Provide detailed specifications and discuss customization needs upfront.

-

Are there warranties and service agreements for cannabis packaging machines?

- Warranties are typically provided for 1 year, but this can vary. Service agreements can be negotiated, including spare parts and maintenance support.

-

What should I consider regarding shipping and import duties?

- Factor in shipping costs, which can be significant due to machine size and weight. Import duties and customs clearance should also be accounted for. Using a freight forwarder can streamline logistics.

-

How can I ensure the machine’s compatibility with my local power supply?

- Verify that the machines can be configured to match your local voltage and frequency standards (e.g., 220V/50Hz). Discuss these requirements with the manufacturer before finalizing your order.

By addressing these key questions, buyers can make more informed decisions when sourcing cannabis packaging machines from China.