Introduction to Tissue Paper Machines

Tissue paper machines have revolutionized the paper industry, enabling mass production of tissue papers that cater to various needs, from personal hygiene to dining etiquette. These machines, with their advanced manufacturing technology, ensure that the tissue papers produced are of high quality, consistent in texture, and hygienic.

China, with its vast manufacturing expertise, has emerged as a global leader in the production of tissue paper machines. With over 30 years of industry experience, Chinese manufacturers have consistently delivered machines that are technologically advanced, durable, and efficient. The country’s commitment to innovation and quality has positioned it as a trusted supplier in the global market, catering to both domestic and international clients.

The rise in awareness about hygiene, especially in the wake of global health crises, has further propelled the demand for tissue papers. Consequently, the tissue paper machine market has witnessed significant growth, with manufacturers constantly upgrading their offerings to meet the evolving needs of consumers.

Types and Applications of Tissue Paper Machines

Tissue paper machines are versatile equipment designed to produce various types of tissue papers. While many associate tissue papers primarily with facial tissues or toilet rolls, the spectrum of products is much broader.

- Toilet Paper Machines: Specifically designed to produce toilet rolls, these machines prioritize bulk production, ensuring rolls are consistent in size, texture, and absorbency. Given the daily necessity of toilet paper, these machines are integral to suppliers worldwide.

- Facial Tissue Machines: These produce softer, high-quality tissues primarily used for facial applications. The emphasis here is on gentleness to avoid skin irritations.

- Paper Napkin Machines: Catering to the hospitality industry, these machines produce napkins of various sizes and textures, often with customizable embossing or printing options.

- Other Specialized Machines: This includes machines for producing products like paper towels, wet wipes, and other specialized tissue products.

The applications of tissue papers are vast. From personal hygiene in households to professional use in industries like hospitality, healthcare, and travel, the demand is ever-present. With the rise in global hygiene awareness, the reliance on tissue paper products has only increased, making the role of tissue paper machines even more pivotal.

The Manufacturing Process in China’s Factories

China’s dominance in the manufacturing sector extends to the production of tissue paper machines. The process involves:

- Raw Material Preparation: Sourcing high-quality paper pulp, which forms the base for tissue papers.

- Pulping and Bleaching: The pulp undergoes a process to achieve the desired consistency and whiteness.

- Sheet Formation: The pulp is then spread into thin sheets.

- Drying and Embossing: The sheets are dried, and desired patterns or textures are embossed onto them.

- Rolling and Cutting: The dried sheets are rolled into large jumbo rolls, which are then cut into smaller, consumer-friendly sizes.

- Quality Control: Rigorous checks ensure that the final product meets the set standards in terms of quality, texture, and absorbency.

Chinese factories prioritize efficiency, quality, and sustainability. With advanced machinery and a skilled workforce, they ensure that the tissue paper production process is streamlined, producing high-quality products at competitive prices.

Customization Options and Services

In the competitive world of tissue paper production, customization is a key differentiator. Recognizing this, many manufacturers, especially those in China, offer a range of customization options to meet the specific needs of their clients.

- Embossing Patterns: Clients can choose from a variety of embossing patterns or even provide their own designs. This allows for brand differentiation and caters to specific market preferences.

- Printing: For those looking to add branding or specific designs to their tissue products, advanced printing options are available. This is especially popular for paper napkins used in the hospitality industry.

- Size and Thickness Customization: Depending on the end-use, clients can specify the size and thickness of the tissue papers they wish to produce, ensuring they cater to their target market effectively.

- Packaging: From bulk packaging for commercial use to individual, consumer-friendly packs, manufacturers offer a range of packaging solutions to meet diverse needs.

Pricing Insights: Factors Influencing the Cost

The price of a tissue paper machine can vary based on several factors:

- Model and Capacity: Higher capacity machines or those with advanced features tend to be priced higher.

- Customization: Any bespoke modifications or custom features can influence the final cost.

- Brand and Reputation: Established brands with a track record of reliability and quality might command a premium.

- After-sales Services: Offerings like extended warranties, regular maintenance checks, and prompt customer service can add to the machine’s cost but provide long-term value.

- Location and Logistics: Import duties, shipping costs, and installation charges can also influence the final price.

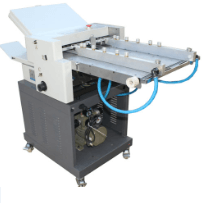

Operational Guidelines and Maintenance Tips

Operating a tissue paper machine efficiently requires understanding its functionalities and regular maintenance:

- Initial Setup: Ensure the machine is set up as per the manufacturer’s guidelines, considering factors like space, power supply, and raw material placement.

- Regular Cleaning: To ensure optimal performance, regularly clean the machine components, especially the rollers and cutting blades.

- Lubrication: Periodically lubricate moving parts to reduce wear and tear.

- Quality Checks: Regularly inspect the produced tissue papers for consistency in quality. Any anomalies can indicate a need for recalibration or maintenance.

- Scheduled Maintenance: Adhere to the maintenance schedule provided by the manufacturer. Regular checks can preempt potential issues, ensuring longevity and consistent performance.

Questions International Buyers Should Ask Chinese Suppliers

When sourcing tissue paper machines from China, international buyers should be thorough in their due diligence:

- What is the machine’s production capacity and speed?

- Can the machine handle different types of paper materials?

- What are the customization options available?

- How do you ensure quality control during the manufacturing process?

- What after-sales services do you offer?

FAQ Tips about Tissue Paper Machine

How energy-efficient are modern tissue paper machines?

- Modern tissue paper machines are designed with energy efficiency in mind. Many models incorporate energy-saving technologies that reduce power consumption without compromising on production speed or quality.

Can the machines produce both recycled and virgin tissue paper?

- Yes, many tissue paper machines are versatile enough to handle both recycled and virgin paper pulp, allowing manufacturers to cater to diverse market demands.

What safety features are typically incorporated in these machines?

- Safety is paramount. Common features include emergency stop buttons, overload protection, automatic shutdown in case of malfunctions, and safety guards around moving parts.

How often should the machine undergo maintenance checks?

- While routine cleaning and basic maintenance should be done regularly, comprehensive maintenance checks are typically recommended every 6-12 months, depending on usage.

What’s the difference between a tissue paper machine and a toilet paper machine?

- While both machines have similar functionalities, a toilet paper machine is specifically designed for producing toilet rolls. Tissue paper machines, on the other hand, can produce a broader range of tissue products, including facial tissues, paper napkins, and more.

How long does it take to set up the machine and start production?

- The setup time can vary based on the model and any custom configurations. However, with proper planning and assistance from the supplier, the setup can often be completed within a few days, allowing production to commence swiftly.

Are there any environmental certifications or standards that the machines comply with?

- Many manufacturers prioritize sustainability and ensure their machines comply with international environmental standards. It’s always a good practice to inquire about any specific certifications the machine holds.

How do technological upgrades impact the machine’s performance?

- Technological upgrades can significantly enhance a machine’s performance, increasing its efficiency, production speed, and even the quality of the tissue paper produced. Manufacturers often provide upgrade options for existing machines.

What factors should be considered when choosing the location for setting up the machine?

- Factors to consider include space availability, proximity to raw material sources, power supply stability, and ease of access for maintenance and repairs.

Can the machine be integrated with other production lines or automation systems?

- Many modern tissue paper machines are designed to be modular and can be integrated with existing production lines or automation systems, ensuring seamless operations.

What is the typical return on investment (ROI) for a tissue paper machine?

- The ROI for a tissue paper machine can vary based on factors like production capacity, operational efficiency, market demand, and product pricing. However, with the ever-present demand for tissue paper products, a well-managed production setup can expect a favorable ROI within a few years.