In today's fast-paced world, convenience has become a paramount factor in consumer choices, especially in the coffee industry. As aficionados look for quicker, hassle-free methods to enjoy their daily brew, the market has seen a surge in innovations. One such groundbreaking invention is the drip coffee bag packing machine.

This machine, a blend of modern technology and efficiency, has transformed the way coffee is packaged and consumed globally. No longer do consumers have to compromise on freshness for convenience. With the advent of these machines, it's now possible to enjoy a fresh cup of coffee anytime, anywhere, without the traditional brewing hassles.

The drip coffee bag packing machine stands as a testament to the industry's commitment to evolving with consumer needs, offering a perfect amalgamation of convenience and quality. This article aims to delve deep into the mechanics, benefits, and applications of these machines, providing insights for both businesses and consumers.

Mechanics of Drip Coffee Bag Packing Machines

The drip coffee bag packing machine is a marvel in the world of coffee packaging. Designed specifically for single servings, these machines ensure that each cup of coffee brewed is as fresh as the last. But how do they achieve this?

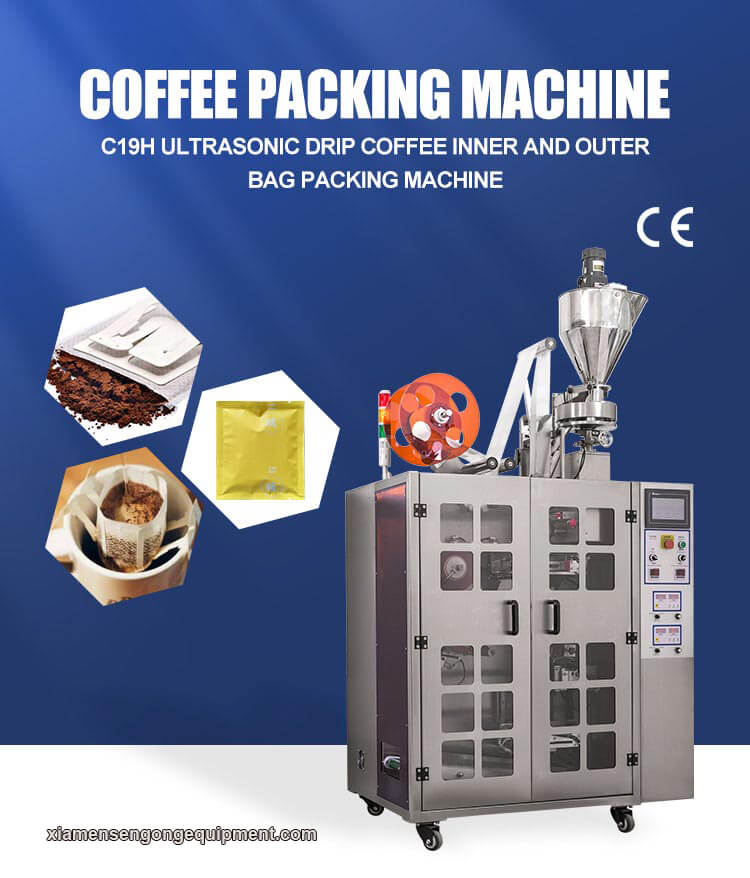

The process commences with the machine dispensing a precise amount of coffee into filter paper. This filter paper, containing the coffee, is then meticulously folded and sealed, forming the 'drip bag'. To further ensure the coffee's freshness and protect it from external elements like moisture and air, the drip bag is enclosed within an outer sachet. This entire procedure, from dispensing to sealing, is completed within seconds, making these machines an indispensable asset for coffee businesses aiming for efficiency and consistency.

Role of Packing Machines in Coffee Quality Preservation

Quality is the cornerstone of the coffee industry. Enthusiasts crave brews that are fresh, aromatic, and full of flavor. Drip coffee bag packing machines play an instrumental role in upholding these standards. By automating the packaging process, they eliminate human error, ensuring each bag contains the perfect amount of coffee. The sealing mechanism protects the coffee from external factors, guaranteeing that consumers experience a fresh and high-quality brew every time they open a drip bag.

Advantages of Using Drip Coffee Bag Packing Machines

The benefits of employing these machines in the coffee packaging process are manifold:

- Efficiency: Automation significantly accelerates production. These machines can package hundreds of drip bags within an hour, a feat unachievable manually.

- Consistency: Each bag is guaranteed to contain the exact coffee amount, ensuring uniformity in every package.

- Cost-effectiveness: Automation reduces manual labor requirements, translating to substantial long-term savings.

- Quality Control: The sealing process ensures optimal protection against external factors, resulting in a fresher and more flavorful brew.

Choosing the Right Supplier: PkgMach.com

When it comes to sourcing quality drip coffee bag packing machines, PkgMach stands out as a premier supplier from China. With a diverse product range, from salt packaging machines to rotary capping machines, they cater to a wide array of business needs. Their commitment extends beyond mere sales; they aim to ensure businesses flourish with the right packaging solutions.

Types and Applications of Coffee Packing Machines

The world of coffee packing is vast and varied, catering to different market needs and preferences. While the C19D non-woven drip Robusta coffee packing machine is a popular choice, there are several other models and types available:

- Ultrasonic Sealing Machines: These utilize ultrasonic waves to create a tight seal, ensuring no coffee granules escape the bag.

- Rotary Capping Machines: Ideal for businesses that also offer bottled coffee, these machines efficiently cap bottles to preserve freshness.

- Auto Wrapping Machines: For larger coffee packages, these machines wrap and seal bulk coffee amounts.

Each machine type serves a unique purpose, catering to different segments of the vast coffee market. Whether it's individual drip coffee bags or bulk coffee packaging, there's a machine tailored for every need.

Production Process in a Factory Setting

Manufacturing a drip coffee bag packing machine is a meticulous process that requires precision, expertise, and a commitment to quality. In China, the production process typically involves:

- Design & Blueprinting: Engineers draft detailed designs of the machine, ensuring every component is optimized for performance.

- Material Sourcing: Only the highest quality materials, like SUS304 stainless steel, are used to ensure longevity and safety.

- Assembly: Skilled technicians assemble the machine, ensuring every component aligns perfectly.

- Quality Control: Rigorous testing is conducted to ensure the machine operates flawlessly. This includes checking the sealing efficiency, measuring the accuracy of coffee dispensing, and ensuring safety protocols are met.

- Packaging & Shipping: Once approved, the machine is securely packaged and shipped to businesses worldwide.

User Guide: Operating the Machine

Operating a drip coffee bag packing machine is straightforward, thanks to user-friendly interfaces and detailed manuals. Here's a basic step-by-step guide:

- Setup: Ensure the machine is placed on a flat surface and plugged into a power source.

- Loading Coffee: Fill the hopper with the desired coffee type.

- Setting Quantity: Use the interface to set the amount of coffee to be dispensed in each bag.

- Starting the Machine: Once settings are confirmed, start the machine. It will automatically dispense, seal, and package the coffee.

- Regular Maintenance: Clean the machine components regularly to ensure optimal performance and longevity.

Questions International Buyers Should Ask Chinese Suppliers

Engaging with suppliers from a different country can be daunting. Here are some crucial questions international buyers should consider when liaising with Chinese suppliers:

- Certifications: "Do your machines come with international quality certifications?"

- Customization: "Can the machines be customized to suit specific requirements?"

- After-sales Support: "What kind of support do you offer post-purchase?"

- Warranty: "Is there a warranty on the machines? If so, what does it cover?"

- Shipping: "How are the machines packaged and shipped to ensure they arrive undamaged?"

- Training: "Do you provide training or tutorials on how to operate the machines?"

- Spare Parts: "Are spare parts readily available?"

- Volume Discounts: "Are there discounts available for bulk purchases?"

- Machine Upgrades: "How often are your machines updated or upgraded?"

- Feedback Mechanism: "Is there a system in place to provide feedback or report issues?"

FAQ Tips about drip coffee bag packing machine

How does the machine ensure consistent coffee quantity in each bag? The machine uses precise dispensers and sensors to ensure each bag gets the exact set amount.

What materials are used for the drip bags? Typically, filter paper or non-woven materials are used, which are both safe and conducive for brewing.

How does the machine maintain coffee freshness? The machine's sealing mechanism ensures an airtight seal, preserving the coffee's aroma and freshness.

What's the difference between different models of packing machines? Each model caters to specific needs, varying in capacity, speed, and sealing methods.

How to choose the right machine based on business size and needs? It's essential to assess your production volume, packaging preferences, and budget to select the ideal machine.