Introduction to CIP Systems

Clean-In-Place (CIP) systems have revolutionized the way industries handle equipment cleaning. These automated systems ensure that machinery is cleaned to the highest standards without the need for manual disassembly. From the food and beverage sector to pharmaceuticals and more, CIP systems play a pivotal role in maintaining hygiene and product quality.

The Science Behind CIP Systems

At its core, a CIP system circulates cleaning agents through machinery to remove product residues, microorganisms, and other contaminants. The process typically involves a pre-rinse, cleaning agent circulation, and a post-rinse cycle. The choice of cleaning agents and the duration of each cycle depend on the equipment and the residues involved.

Top Mistakes to Avoid in CIP System Designs

A well-designed CIP system is pivotal for efficient cleaning, but even minor oversights can compromise its effectiveness. Here are some common pitfalls:

- Incorrectly Sized Pumps and Piping: This can lead to high or low flow and pressure, potentially causing cavitation in the CIP delivery pump or atomization of the cleaning solution.

- Mis-sized CIP Tanks: Tanks that are too small or too large can disrupt the cleaning process, leading to inefficiencies and wastage.

- Inappropriate Return Pumps: Pumps that aren't self-priming can result in incomplete recovery of the cleaning solution, wasting chemicals and time.

- Wrong Cleaning Machines: It's crucial to match the type and size of the cleaning machine to the vessel being cleaned.

- Lack of Continuous Monitoring: Without monitoring factors like chemical strength, temperature, and volume, there's a risk of under-dosing or over-dosing chemicals and mismanaging heating solutions.

Benefits of Investing in a Quality CIP System

A robust CIP system is more than just a cleaning tool; it's an investment in product quality, efficiency, and brand reputation. Key benefits include:

- Consistent Cleaning: Ensuring every cycle meets the desired hygiene standards.

- Resource Efficiency: Reducing water, energy, and chemical consumption.

- Extended Equipment Lifespan: Regular and thorough cleaning can prolong the life of machinery, reducing maintenance and replacement costs.

Types and Applications of CIP Systems

CIP systems can be categorized based on their size, functionality, and the industries they serve. Common types include:

- Single-Tank Systems: Suitable for simpler processes with one cleaning agent.

- Multi-Tank Systems: Designed for complex cleaning requirements involving multiple agents.

- Mobile CIP Systems: Portable units ideal for facilities with space constraints or multiple cleaning points.

Applications span across sectors, from dairy processing and beverage production to pharmaceutical manufacturing and more.

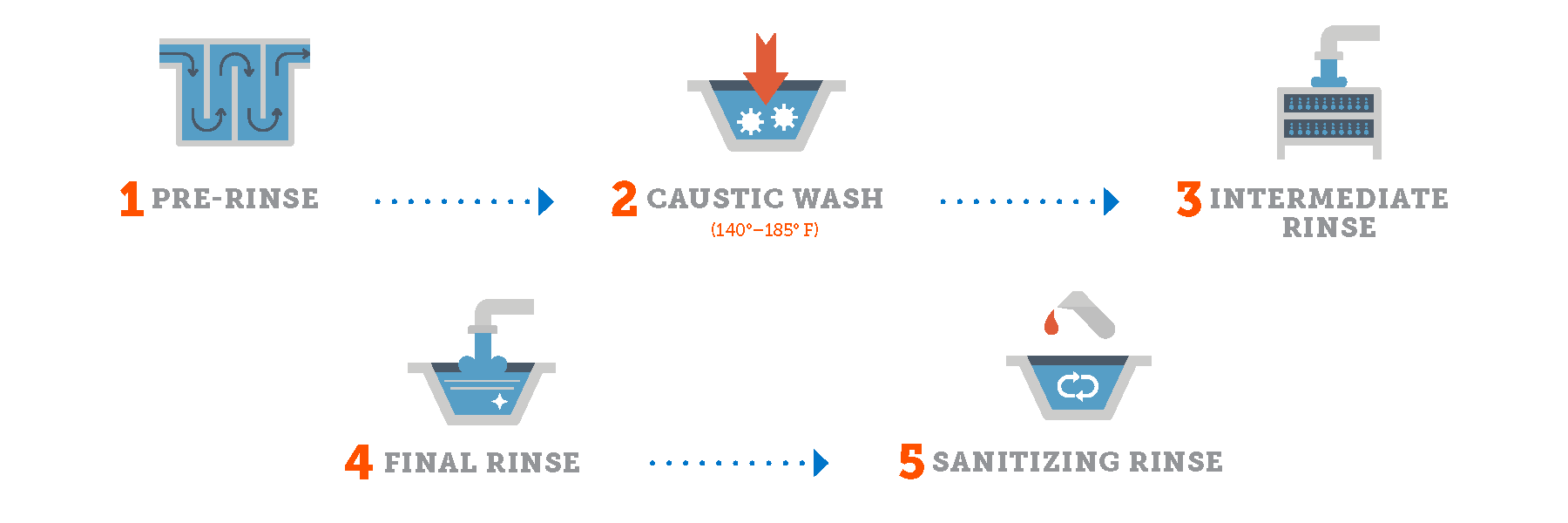

Step-by-Step Guide to Operating a CIP System

Operating a CIP system efficiently not only ensures optimal cleaning but also prolongs the system's lifespan. Here's a detailed guide:

Initial Setup:

- Ensure the system is connected to all equipment requiring cleaning.

- Check for any visible leaks or damages.

- Ensure all valves are in their correct positions.

Pre-rinse Phase:

- Initiate the pre-rinse cycle, which uses water to remove the majority of the residue.

- Monitor the return water's clarity. Once clear, move to the next phase.

Cleaning Phase:

- Introduce the cleaning agent into the system.

- Set the desired temperature and circulation time based on the cleaning agent and residue type.

- Allow the solution to circulate, ensuring all equipment surfaces are contacted.

Rinse Phase:

- After the cleaning phase, rinse the system with water to remove any cleaning agent residues.

- Monitor the return water for any signs of the cleaning agent. Continue rinsing until it's clear.

Sanitization (if required):

- If the equipment requires sanitization, introduce the sanitizing agent.

- Circulate as per the manufacturer's recommendations.

Drain and Prepare for Next Use:

- Once all cycles are complete, drain the system.

- Prepare it for the next use or storage.

Key Questions International Buyers Should Ask Their Chinese Suppliers

Sourcing a CIP system from China requires due diligence. Here are essential questions to ask:

- What certifications do your CIP systems adhere to?

- Can you customize the CIP system based on our specific requirements?

- How do you handle installation and training?

- What post-sales support do you offer, especially for international clients?

- Can you provide references or case studies of previous installations?

The Manufacturing Process at PkgMach's Factory

PkgMach's reputation for top-tier CIP systems stems from its meticulous manufacturing process:

Design and Blueprinting: Engineers conceptualize and design the system, ensuring it meets industry standards and client requirements.

Material Procurement: Only the highest quality materials, resistant to corrosion and wear, are selected.

Assembly: Precision is paramount. Each component is assembled with care, ensuring seamless operation.

Quality Checks: Rigorous testing ensures each CIP system functions optimally and safely.

Packaging and Shipping: Systems are securely packaged, ready for domestic or international shipping.

FAQ Tips

- What exactly is a CIP system?

- A CIP (Clean-In-Place) system is an automated method of cleaning the interior surfaces of pipes, vessels, process equipment, filters, and associated fittings, without disassembly.

- How does a CIP system differ from manual cleaning?

- CIP systems offer automated, consistent, and efficient cleaning without the need for manual disassembly, reducing labor costs and minimizing downtime.

- Why is PkgMach's CIP system considered superior?

- PkgMach's CIP systems are designed for optimal performance, durability, and efficiency. They are customizable, made from high-quality materials, and are backed by the company's stellar after-sales service.

- Can CIP systems handle different cleaning agents?

- Yes, CIP systems can be designed to handle various cleaning agents, from caustic solutions to acids, depending on the cleaning requirement.

- How often should a CIP system be operated?

- The frequency depends on the production schedule, type of product processed, and specific hygiene standards of an industry. Some facilities run CIP daily, while others might do it weekly.

- What factors affect the cleaning efficiency of a CIP system?

- Cleaning efficiency can be influenced by the choice of cleaning agent, temperature, contact time, flow rate, and system design.

- Is there a risk of cross-contamination in CIP systems?

- Properly designed and operated CIP systems minimize the risk of cross-contamination. Regular maintenance and checks are essential to ensure system integrity.

- How energy-efficient are PkgMach's CIP systems?

- PkgMach's CIP systems are designed for maximum energy efficiency, reducing operational costs and environmental impact.

- What's the ROI on investing in a CIP system from PkgMach?

- While the initial investment might be significant, the long-term benefits in terms of labor savings, reduced downtime, consistent product quality, and extended equipment lifespan offer a substantial ROI.

- How does PkgMach support international clients post-purchase?

- PkgMach offers comprehensive after-sales support, including installation guidance, training, maintenance tips, and prompt customer service for all international clients.

In the realm of industrial cleaning, CIP systems have emerged as game-changers. Their ability to ensure consistent, efficient, and thorough cleaning has made them indispensable in various sectors. PkgMach, with its commitment to quality and innovation, stands at the forefront, offering CIP systems that promise reliability, efficiency, and a competitive edge. For businesses aiming to elevate their cleaning processes, investing in a PkgMach CIP system is a decision that pays dividends in the long run.