List Technical Parameters of "Coffee Packaging Machine"

A coffee packaging machine is a specialized device designed for the automated packaging of coffee products. It involves a collection of technical parameters that ensure the efficient, accurate, and hygienic packaging of coffee. Here is a concise list of these parameters:

1. Capacity and Speed: The output rates (bags or packages per minute) and maximum throughput (kg/hr).

2. Bag Size Range: Specifications for minimum and maximum dimensions (such as width, length, and height) of the coffee bags.

3. Filling Accuracy: The precision of the filling system, typically specified as a percentage error or standard deviation.

4. Sealing Mechanism: Details about the type of sealing used, such as heat seal, ultrasonic seal, or vacuum seal capabilities.

5. Material Compatibility: Types of packaging materials supported (e.g., plastic films, laminates, paper, etc.).

6. Power Requirements: Electrical specifications including voltage, current, and frequency.

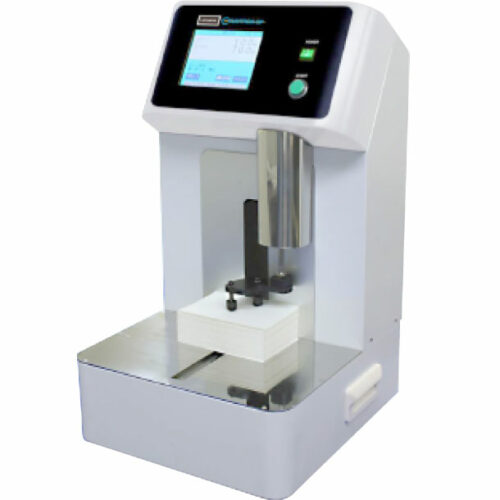

7. Control System: The type of control system in use, such as PLC (Programmable Logic Controller) or HMI (Human-Machine Interface) with touchscreen functionality.

8. Dimensions and Weight: Physical dimensions (height, width, depth) and overall weight of the machine.

9. Hopper Capacity: Volume of the coffee hopper typically in liters or kilograms.

10. Air Supply: Pneumatic requirements including pressure and flow rate.

11. Operational Modes: Different modes the machine can operate in, such as batch mode, continuous mode, or manual mode.

12. Speed Adjustability: Capability for adjusting speed settings based on packaging needs.

13. Environmental Specifications: Operational temperature and humidity ranges.

14. User-friendly Features: Easy-to-clean surfaces, quick-change mechanisms for different bag sizes, and accessibility for maintenance.

15. Compliance and Safety Standards: Adherence to local and international safety and hygiene standards (e.g., CE certification, GMP compliance).

These parameters not only help in selecting the right machine but also ensure that the machine meets production requirements efficiently.

List Product features of "Coffee Packaging Machine"

1. Automated Functionality: Streamlines the entire packaging process from filling to sealing, reducing labor costs and increasing efficiency.

2. Versatile Bag Styles: Accommodates various packaging styles such as pouches, sachets, and stand-up bags, catering to diverse market needs.

3. Adjustable Size Range: Offers flexibility in packaging sizes, supporting different volume requirements from small sample packs to large bulk bags.

4. Precision Weighing System: Equipped with high-accuracy weighing mechanisms to ensure consistent product quantity in each package, minimizing waste.

5. High-Speed Operation: Capable of producing multiple packets per minute, increasing productivity and meeting high-demand cycles.

6. Durable Construction: Built with robust materials to withstand continuous operation and harsh industrial environments, ensuring longevity.

7. User-Friendly Interface: Touchscreen controls and intuitive software allow for easy operation, minimal training time, and quick troubleshooting.

8. Customizable Settings: Programmable parameters, including filling speed, bag length, and sealing temperature, allow for tailored packaging solutions.

9. Nitrogen Flushing: Incorporates nitrogen flushing to preserve coffee freshness by minimizing oxidation, extending shelf life.

10. Sealing Technology: Advanced sealing methods, like heat or ultrasonic sealing, ensure airtight and tamper-evident packaging.

11. Safety Features: Equipped with emergency stop buttons, safety guards, and error detection systems to ensure safe operation.

12. Integrated Date Coding: Seamlessly prints production dates, expiry dates, and batch numbers for traceability and compliance with regulations.

13. Eco-Friendly Options: Supports the use of biodegradable or recyclable packaging materials to meet sustainable packaging standards.

14. Compact Footprint: Designed to occupy minimal floor space, making it suitable for small to medium-sized production areas.

15. Low Maintenance: Features components that require minimal maintenance, reducing downtime and maintenance costs.

16. Compatibility: Compatible with additional equipment like grinders, hoppers, and conveyor systems for a fully integrated production line.

Leveraging these features, a coffee packaging machine enhances efficiency, quality, and operational productivity in coffee production and packaging processes.

List Application of "Coffee Packaging Machine"

A coffee packaging machine is a specialized apparatus designed to handle various tasks related to the packaging of coffee products. Its applications are numerous, enhancing efficiency, ensuring quality, and maintaining freshness. Here are some key applications:

1. Sealing and Containment:

The primary purpose of a coffee packaging machine is to seal coffee products into bags, pouches, or pods. This ensures that the coffee remains fresh and is protected from external factors like air, moisture, and light.

2. Vacuum Packaging:

For premium coffee products, vacuum packaging is essential to maximize shelf life. The machine removes air from the package before sealing, drastically reducing oxidation and preserving the aroma and flavor.

3. Pre-measured Portion Control:

Many machines offer precise measurement and portioning, ensuring that each package has an exact amount of coffee. This is especially important for single-serve pods or pre-ground coffee packages.

4. Customization and Branding:

Packaging machines can apply custom labels, prints, and branding materials directly onto the coffee package. This allows companies to maintain brand consistency and meet market-specific requirements.

5. Automated Filling:

Automated filling systems ensure fast and hygienic loading of coffee into packages. This reduces the need for manual labor, enhances efficiency, and minimizes contamination risks.

6. Quality Control:

Advanced coffee packaging machines often come equipped with quality control systems that can detect and reject packages that aren’t sealed properly or do not meet weight specifications.

7. Various Packaging Formats:

These machines are versatile and can handle different types of packaging materials, such as paper, plastic, and foil, accommodating diverse market needs.

8. Enhanced Shelf Appeal:

By producing professionally sealed and attractively branded packages, these machines help enhance the product’s shelf appeal, making it more attractive to consumers.

9. Energy and Resource Efficiency:

Modern coffee packaging machines are designed to be energy-efficient and reduce material waste, contributing to more sustainable manufacturing processes.

10. Production Scalability:

They can handle a wide range of production volumes, from small batch, artisanal coffee producers to large-scale commercial coffee manufacturers, making it easier to scale operations up or down based on demand.

These varied applications demonstrate how coffee packaging machines play a critical role in the coffee supply chain, from production to the end-user.

List Various Types of "Coffee Packaging Machine"

Certainly! Various types of coffee packaging machines cater to different packaging needs and coffee forms (beans, grounds, pods). Here are some key types:

-

Vertical Form Fill Seal (VFFS) Machines

– Description: Automate the process of forming, filling, and sealing pouches from a flat roll of film.

– Suitable For: Ground coffee, coffee beans.

– Advantages: High-speed operation, versatility in packaging formats. -

Horizontal Form Fill Seal (HFFS) Machines

– Description: Forms pouches horizontally and is ideal for various styles like pillow bags.

– Suitable For: Coffee pods, single-serve packs.

– Advantages: Versatile, suitable for diverse packaging styles. -

Pre-made Pouch Packaging Machines

– Description: Fill and seal pre-made pouches.

– Suitable For: Ground coffee, coffee beans.

– Advantages: High-quality seals, suitable for premium products. -

Stick Pack Machines

– Description: Create narrow tubes for single servings.

– Suitable For: Instant coffee.

– Advantages: Convenient portion control, compact design. -

Flat Bottom Bag/Gusseted Bag Packaging Machines

– Description: Create bags with flat bottoms, which provide self-standing capabilities.

– Suitable For: Coffee beans, ground coffee.

– Advantages: Shelf appeal, better presentation, efficient storage. -

Coffee Pod/Capsule Filling and Sealing Machines

– Description: Specialize in filling and sealing single-serve coffee pods/capsules.

– Suitable For: Single-serve coffee products.

– Advantages: Precision filling, efficient sealing, caters to the growing single-serve market. -

Multi-lane Stick Packing Machines

– Description: Produce multiple sticks simultaneously.

– Suitable For: Instant coffee.

– Advantages: High output, efficient for large batches. -

Vacuum Packing Machines

– Description: Remove air from the package before sealing.

– Suitable For: Ground coffee, coffee beans.

– Advantages: Extends shelf life, maintains freshness. -

Vacuum Sealing Machines for Ground Coffee

– Description: Specialized for sealing vacuum packs of ground coffee.

– Suitable For: Ground coffee.

– Advantages: Prevents oxidation, maintains aroma.

Custom Manufacturing Options for Coffee Packaging Machine

Custom manufacturing options for coffee packaging machines offer various benefits tailored to specific business needs. These options include:

1. Machine Size and Capacity: Custom machines can be designed to match the production scale, whether for small artisanal operations or large-scale industrial production.

2. Packaging Types: Options include drip bags, pouches, vacuum packs, and K-cups. Customization allows the machine to handle multiple packaging formats or specialize in one, depending on business requirements.

3. Material Compatibility: Machines can be designed to handle different materials such as paper, plastic, or biodegradable options, aligning with sustainability goals and brand identity.

4. Sealing Methods: Choices include heat sealing, ultrasonic sealing, and adhesive sealing. Each method offers different benefits in terms of speed, cost, and seal integrity.

5. Automation Level: Customization in automation allows for a range of options from semi-automatic to fully automatic machines, integrating features like weighing, filling, sealing, and labeling.

6. Integration with Existing Systems: Custom machines can be tailored to integrate seamlessly with existing production lines, reducing the need for extensive reconfiguration and ensuring smooth operations.

7. Customization in Aesthetics: This could involve branding elements or specific design features to ensure the machine aligns with a company’s visual identity.

8. Advanced Technology Features: Inclusion of IoT capabilities, real-time monitoring, and AI-based predictive maintenance can enhance efficiency and reduce downtime.

9. Modular Design: Allowing for future expansion and upgrades, a modular approach enables businesses to adapt quickly to changing market demands.

10. Compliance and Safety Standards: Machines can be tailored to meet specific industry regulations and safety standards ensuring product quality and worker safety.

Custom manufacturing ensures that coffee packaging machines are precisely aligned with a business’s operational needs and market focus, enhancing efficiency, reducing costs, and supporting sustainable practices.

List Quality Control and The Manufacturing Process of "Coffee Packaging Machine"

Quality Control

1. Raw Material Inspection: Verify the quality and specifications of metals, electronics, and other materials.

2. Precision Machining: Use advanced CNC machines for precise component fabrication.

3. Assembly Checks: Inspect mechanical and electrical assemblies for accuracy.

4. Calibration: Ensure sensors and calibration devices are properly set.

5. Functional Testing: Run the machine to verify operating parameters like speed, accuracy, and safety functions.

6. Quality Audits: Regular inspections by quality auditors to ensure compliance with standards such as ISO 9001.

7. Final Verification: Conduct a thorough final review before packaging for shipment.

Manufacturing Process

1. Design & Prototyping: Begin with product design using CAD software. Create initial prototypes for testing.

2. Material Acquisition: Procure high-quality materials required for building the coffee packaging machine.

3. Component Manufacturing: Use precision machining (CNC) to create components like gears, shafts, and frames.

4. Electronic Assembly: Assemble electronic components, including sensors, controllers, and wiring.

5. Subsystem Assembly: Combine mechanical and electronic parts into larger subsystems (e.g., filling, sealing units).

6. Quality Control: Conduct intermediate quality checks on each subsystem.

7. Main Assembly: Integrate all subsystems into the main machine framework.

8. Calibration & Testing: Calibrate the machine, run performance and safety tests.

9. Software Integration: Install and test control software to ensure functional operation.

10. Finishing: Apply coatings or treatments to protect against corrosion and wear.

11. Packaging: Ensure the machine is clean, include manuals, and package for secure delivery.

By adhering to stringent quality control protocols and precise manufacturing steps, consistency and reliability in Coffee Packaging Machines are achieved.

How to use "Coffee Packaging Machine"

Using a coffee packaging machine efficiently involves several key steps to ensure your coffee is expertly packaged, maintaining its freshness and quality. Here’s a concise guide:

1. Preparation

a. Gather Supplies: Ensure you have coffee beans, packaging material (such as bags or pouches), labels, and any additional accessories like valves.

b. Check Machine Settings: Make sure the machine is clean and set up according to the manufacturer’s guidelines. Adjust the settings based on the type and size of the packaging material.

2. Loading the Machine

a. Fill the Hopper: Pour the coffee beans into the machine’s hopper. Ensure the beans are appropriately roasted and cooled.

b. Set Packaging Material: Load the packaging material into the designated area. Position it correctly to prevent misalignment.

3. Calibration

a. Adjust Weight Settings: Set the desired weight for each package. Most machines allow you to customize this based on the packaging needs.

b. Temperature and Seal Settings: Configure the machine’s sealing temperature and pressure according to the material specifications. This ensures a proper, airtight seal.

4. Operation

a. Start the Machine: Power on the machine and initiate the packaging process. Monitor the operation to ensure everything runs smoothly.

b. Quality Check: Periodically check the packages to ensure they are sealed correctly and meet quality standards.

5. Troubleshooting

a. Resolve Issues: If the machine jams or misaligns packaging, stop the machine and address the issue. Common problems include incorrect weight or sealing errors.

6. Maintenance

a. Clean Regularly: After use, clean the machine to prevent coffee oil buildup and maintain hygiene.

b. Scheduled Maintenance: Follow the manufacturer’s maintenance schedule for optimal performance and longevity of the machine.

Final Tips

– Safety First: Always follow safety guidelines to avoid accidents.

– Consistent Monitoring: Regularly check for wear and tear or parts that may need replacement.

– User Manual: Refer to the user manual for specific instructions related to your machine model.

Using this guide, you can efficiently operate a coffee packaging machine to ensure your coffee products are well-preserved and professionally presented.

List Properties and Terms of "Coffee Packaging Machine"

Properties and Terms of Coffee Packaging Machine

1. Material Compatibility:

- Designed to handle various packaging materials including plastic, foil, paper, and composite films.

- Compatibility with sustainable and recyclable materials.

2. Speed and Efficiency:

- High-speed operation to increase production rates.

- Variable speed settings to match different production needs.

3. Automation Levels:

- Semi-automatic and fully automatic systems available.

- Advanced models with robotic arms for precision and speed.

4. Bag Types:

- Supports multiple bag styles such as stand-up pouches, flat-bottom bags, sachets, and gusseted bags.

- Customizable sizes for different packaging needs.

5. Filling Mechanisms:

- Volumetric fillers, auger fillers, and weighers for accuracy.

- Multi-head weighers for high precision and speed.

6. Sealing Techniques:

- Heat sealing for airtight packages.

- Ultrasonic and impulse sealing options for specific materials.

7. Controls and Interface:

- User-friendly touchscreen controls.

- Programmable Logic Controllers (PLCs) for customizable settings.

8. Quality Control:

- In-line check weighers for weight accuracy.

- Metal detectors and X-ray inspection systems for quality assurance.

9. Maintenance and Durability:

- Easy-to-clean designs with stainless steel construction.

- Modular parts for easy replacement and maintenance.

10. Customization Options:

- Customizable to accommodate branding and labeling requirements.

- Print and apply labeling systems for barcodes and QR codes.

11. Energy Efficiency:

- Energy-efficient models to reduce operational costs.

- Eco-friendly designs to minimize environmental impact.

12. Safety Features:

- Integrated safety guards and emergency stop buttons.

- Compliance with international safety standards and regulations.

13. Additional Features:

- Integrated nitrogen flush systems to preserve freshness.

- Options for resealable zip closures and degassing valves.

List The Evolution history of "Coffee Packaging Machine"

The evolution of coffee packaging machines reflects the dynamic transformation of the coffee industry and broader technological progress.

Early 20th Century: The first coffee packaging efforts were manual, with workers hand-packing ground coffee into bags. These primitive methods were labor-intensive and inconsistent in maintaining product freshness.

1940s-1950s: The post-World War II era ushered in mechanization. Machines began to emerge that could handle basic tasks like filling and sealing. The materials evolved from simple paper to more durable materials like aluminum foil to preserve freshness.

1960s-1970s: The advent of vacuum packaging was a significant leap. Vacuum sealing extended coffee shelf life by removing air, which is detrimental to coffee quality. Automatic machines started to incorporate this technology.

1980s: The development of one-way degassing valves revolutionized coffee packaging. These valves allowed carbon dioxide to escape from freshly roasted coffee without letting air in. Machines integrated this technology, offering better preservation and flavor retention.

1990s: Stand-up pouches with resealable features became popular. Packaging machines adapted to accommodate these flexible, consumer-friendly formats. Additionally, computerization improved precision and efficiency.

Early 2000s: Single-serve coffee pods and capsules hit the market, driven by consumer demand for convenience. Packaging machines evolved to handle the intricate processes of forming, filling, and sealing these pods.

2010s – Present: The focus shifted to sustainability and smart technology. Machines became more energy-efficient and capable of using eco-friendly materials. Automation and robotics now dominate, increasing speed and reducing human error. IoT (Internet of Things) started enhancing machine diagnostics and maintenance.

Future Trends: Innovations continue with emphasis on biodegradable packaging, real-time quality control, and further automation aimed at customizing packaging on demand. The synergy of AI and machine learning will likely drive future advancements, making machines smarter and more responsive to market needs.

How to Select a Reliable Coffee Packaging Machine

Selecting a reliable coffee packaging machine is crucial for ensuring product quality, efficiency, and cost-effectiveness. Here are key considerations to guide your choice:

1. Production Needs: Assess your production volume. For small-scale operations, a semi-automatic machine might suffice, while large-scale production may require fully automatic, high-speed machines.

2. Packaging Types: Determine the type of packaging you need—bean bags, ground coffee pouches, or single-serve pods. Each format may require different machinery.

3. Material Compatibility: Ensure the machine can handle your packaging materials, whether it’s plastic, paper, or foil.

4. Sealing Quality: Check for consistent and airtight sealing capabilities to maintain freshness and extend shelf life.

5. Ease of Use and Maintenance: Choose a machine that offers ease of operation and maintenance. User-friendly interfaces and accessible components can reduce downtime and labor costs.

6. Customization and Flexibility: Opt for machinery that offers flexibility for future product variations or packaging changes. Customizable settings can adapt to different sizes and weights.

7. Energy Efficiency: Consider machines with low energy consumption to reduce operational costs and support sustainability efforts.

8. Reputable Manufacturer: Select a machine from a reputable manufacturer known for quality and reliable after-sales support. Review customer testimonials and case studies.

9. Compliance and Certification: Ensure the machine complies with industry standards and certifications (e.g., CE, UL) for safety and quality.

10. Budget: Balance between cost and functionality. While cheaper models can be tempting, investing in a durable, high-quality machine can offer better long-term value.

11. Service and Support: Evaluate the availability of technical support, spare parts, and training. Reliable after-sales service is crucial for operational continuity.

By considering these factors, you can select a coffee packaging machine that meets your production requirements and contributes to efficient, high-quality packaging.

List "Coffee Packaging Machine" FAQ

Coffee Packaging Machine FAQ

-

What types of coffee can be packaged?

- Ground coffee, whole beans, and instant coffee.

-

What packaging formats are supported?

- Bags, pouches, pods, and cans.

-

What are the machine’s capacity and speed?

- Varies by model; typically ranges from 30 to 100 bags per minute.

-

Is the machine suitable for small and large-scale operations?

- Yes, machines can be tailored for both small-scale artisanal operations and large-scale industrial production.

-

How is product freshness ensured?

- Features include degassing valves, nitrogen flushing, and hermetic sealing.

-

Can the machine handle different packaging materials?

- Yes, it supports materials like plastic, paper, foil, and biodegradable materials.

-

Is the machine easy to operate and maintain?

- Yes, most models come with user-friendly touchscreens and automated cleaning systems.

-

What safety features are included?

- Safety guards, emergency stop buttons, and compliance with international safety standards.

-

Does the machine offer customization options?

- Yes, settings for different bag sizes, shapes, and sealing methods can be customized.

-

How long does installation take?

- Generally, installation can be completed within a few days, including setup and basic training.

-

What kind of technical support is available?

- Most suppliers offer remote support, on-site service, and training programs.

-

What’s the initial investment and operational cost?

- Prices range widely based on features and capacity; suppliers often provide quotes upon request.

-

Can the machine integrate with other equipment?

- Yes, it can be integrated with grinders, weighers, and conveyor systems for a streamlined process.

-

What is the machine’s energy consumption?

- Energy consumption varies; energy-efficient models are available to reduce operational costs.

-

What’s the warranty and after-sales support like?

- Warranties typically range from one to three years, with various after-sales services offered.

This comprehensive FAQ should address most initial queries regarding coffee packaging machines. Always consult with manufacturers for details specific to your needs.

Top 10 FAQ with answer about Coffee Packaging Machine for Buyer Sourcing from China

Certainly! Here are the top 10 FAQs along with their succinct answers for buyers sourcing coffee packaging machines from China:

-

What types of coffee packaging machines are available?

- Options include vacuum packagers, vertical form fill seal (VFFS) machines, sachet packaging machines, and pod/capsule filling machines, each designed for different coffee products and packaging styles.

-

What is the typical lead time for a coffee packaging machine from China?

- Lead times can vary but typically range from 30 to 60 days, depending on the complexity of the machine and customization requirements.

-

How do I ensure the quality of the machine?

- Ensure the supplier is reputable, check certifications (like CE, ISO9001), request for past customer references, and, if possible, visit the factory or arrange for third-party inspections.

-

Can the machine be customized for specific packaging requirements?

- Yes, most manufacturers offer customization based on package size, type, and additional features like labeling and date stamping.

-

What are the payment terms offered by Chinese suppliers?

- Common terms include a down payment (30%-50%) with the balance paid before shipment. L/C (Letter of Credit) is also a secure method for large transactions.

-

What after-sales service and support are available?

- Suppliers typically offer installation support, operator training, and a warranty period (usually one year). Ensure support for spare parts, maintenance, and technical assistance.

-

How is the machine shipped, and what are the logistics costs?

- Machines are usually shipped via sea freight in sturdy wooden crates. Costs vary based on machine size, weight, and destination. Discuss Incoterms (like FOB or CIF) with your supplier.

-

Are there language barriers in dealing with suppliers?

- While many suppliers have English-speaking sales teams, it’s essential to agree on clear communication methods and terms to avoid misunderstandings.

-

What power requirements do these machines have?

- Most machines run on 220V or 380V, three-phase power. Verify compatibility with your country’s power standards.

-

What should be considered in terms of import duties and taxes?

- Import duties and taxes depend on your country’s regulations. Consult a customs broker for accurate estimates and ensure all necessary documentation is provided by the supplier.

This concise guide should help streamline the sourcing process and address common concerns efficiently.