List Technical Parameters of "container filling equipment"

When evaluating container filling equipment for industrial or commercial use, it’s crucial to consider various technical parameters to ensure efficiency, accuracy, and compatibility with specific needs. Here are the primary technical parameters to examine:

1. Filling Speed:

- Measured in containers per minute (cpm).

- Influences overall production throughput.

2. Accuracy:

- Precision of the fill weight or volume.

- Typically expressed as a percentage of the target fill (e.g., ±0.5%).

3. Filling Volume/Weight Range:

- Minimum and maximum capacity the equipment can handle.

- Critical for ensuring flexibility across different container sizes.

4. Type of Filling Mechanism:

- Options include gravity, piston, pump, overflow, or volumetric fillers.

- Must be chosen based on the nature of the product being filled (liquid, powder, granular, viscous).

5. Container Compatibility:

- Range of container shapes and sizes it can accommodate.

- Adaptability to different materials (glass, plastic, metal).

6. Material Construction:

- Stainless steel is common for food-grade and pharmaceutical applications to ensure hygiene and durability.

- Corrosion-resistant materials for chemical applications.

7. Automation Level:

- Manual, semi-automatic, or fully automatic.

- Integration with existing production lines and conveyors.

8. CIP/SIP Capability:

- Clean-in-place (CIP) or Sterilize-in-place (SIP) features for ease of maintenance and sanitary compliance.

9. Control System:

- PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) for user-friendly operation and monitoring.

- Remote diagnostics and IoT integration (Industry 4.0).

10. Power Requirements:

- Electrical specifications including voltage and power consumption.

- Air requirements for pneumatic systems.

11. Footprint and Dimensions:

- Overall size of the equipment.

- Space considerations for installation in the production area.

12. Compliance and Certification:

- Relevant certifications like CE, UL, FDA, or GMP standards depending on the industry.

13. Maintenance and Durability:

- Ease of accessing parts for servicing.

- Expected lifespan and warranty.

These parameters guide the selection process to align the equipment with operational demands and regulatory requirements, ensuring optimal performance and a return on investment.

List Product features of "container filling equipment"

Container filling equipment is integral to various industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. Here are key features typically present in modern container filling machines:

1. Precision and Accuracy

- High-Precision Sensors: Equipped with advanced sensors to ensure exact fill levels.

- Digital Calibration: For precise adjustment and maintaining consistency in filling.

2. Versatility

- Multiple Container Compatibility: Can handle various container shapes and sizes, from bottles to jars to pouches.

- Adjustable Settings: Easily adaptable for different types of liquids, including thick, viscous, and foamy liquids.

3. Speed and Efficiency

- High-Speed Operation: Capable of filling multiple containers per minute, improving production rates.

- Automated Processes: Integration with conveyor systems for non-stop operation.

4. User-Friendly Interface

- Touchscreen Controls: Intuitive, programmable interfaces for easy operation and monitoring.

- Error Detection: Automatic error detection and alarms to reduce downtime.

5. Hygiene and Safety

- Sanitary Design: Made from stainless steel and other food-grade materials to ensure compliance with hygiene regulations.

- Easy Cleaning: Simple disassembly and CIP/SIP (Clean-In-Place/Sterilize-In-Place) features.

6. Customization

- Modular Design: Customizable components to fit specific production needs.

- Multiple Nozzles: Options for different nozzle types and configurations to optimize filling.

7. Flexibility

- Scalability: Suitable for small-scale operations and expandable for large-scale manufacturing.

- Multiple Liquid Types: Compatible with both free-flowing and viscous liquids.

8. Energy Efficiency

- Low Power Consumption: Engineered to be energy-efficient without compromising performance.

- Eco-friendly Options: Available in models that reduce waste and energy usage.

9. Durability and Reliability

- Robust Construction: Built with durable materials to withstand industrial environments.

- Maintenance Alerts: Predictive maintenance features to minimize machine downtime.

10. Integration Capabilities

- Connectivity: Compatible with factory automation systems and ERP software.

- Data Collection and Analysis: Advanced monitoring for performance analytics and quality control.

By incorporating these features, container filling equipment ensures efficiency, reliability, and versatility, meeting the diverse needs of various industries.

List Application of "container filling equipment"

Container filling equipment is essential across a myriad of industries for its ability to efficiently and accurately fill containers with various products. Here are some key applications:

1. Food and Beverage Industry: This equipment is used to fill bottles, cans, and jars with products like water, juices, sauces, oils, and carbonated drinks. It ensures hygiene, precision, and speed, which are crucial for maintaining product quality and meeting consumer demand.

2. Pharmaceutical Industry: Precision is paramount here. Container filling equipment is employed to fill vials, ampoules, and bottles with medicines, syrups, and other liquid formulations, ensuring correct dosages and adherence to stringent regulatory standards.

3. Cosmetics and Personal Care: For products like lotions, creams, shampoos, and perfumes, container filling equipment provides consistency and efficiency in packaging, aiding in maintaining product integrity and enhancing brand presentation.

4. Chemical Industry: This equipment is used for filling containers with various chemicals, including cleaning agents, solvents, and industrial lubricants. The robust design often caters to corrosive and hazardous materials, ensuring safety and compliance with industry regulations.

5. Agriculture: In this sector, it's used to fill containers with fertilizers, pesticides, and animal feed supplements. This ensures precise measurements, reducing wastage and enhancing product efficacy.

6. Household Goods: Container filling equipment facilitates the packaging of products like detergents, disinfectants, and polishes. It ensures consistency in product quantity and helps meet production targets efficiently.

7. Paints and Coatings: Used to fill cans, pails, and buckets with paints, varnishes, and other coatings, this equipment ensures even and precise filling, crucial for quality control and customer satisfaction.

8. Petroleum and Lubricants: This sector utilizes filling equipment for packaging oils, greases, and other lubricants, ensuring accurate volume control and reducing spillage during the filling process.

In all these applications, container filling equipment enhances operational efficiency, ensures product quality, and reduces labor costs, making it an indispensable tool in modern industrial practices.

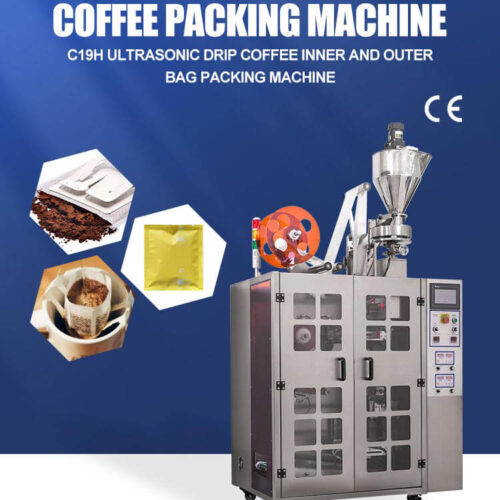

List Various Types of "container filling equipment"

Container filling equipment is essential in various industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals to efficiently fill containers with liquid, powder, or granular products. Here's a concise list of different types of container filling equipment:

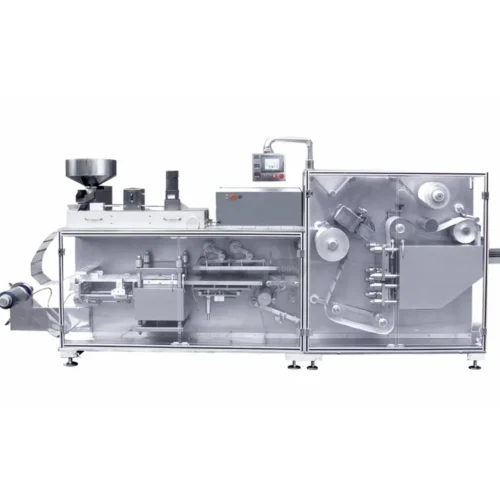

1. Liquid Filling Machines: Designed for filling liquids and semi-liquids.

- Piston Fillers: Ideal for thick liquids like sauces and creams.

- Gravity Fillers: Suitable for thin, free-flowing liquids.

- Pump Fillers: Used for liquids with various viscosities.

- Overflow Fillers: Ensure consistent fill levels for transparent containers.

2. Powder Filling Machines: Specifically for powder products.

- Auger Fillers: Use a rotating screw to dispense precise amounts of powder.

- Cup Fillers: Measure powder volume using a cup or scoop mechanism.

- Net Weight Fillers: Weigh powder to achieve accurate fill weight.

3. Granular Filling Machines: For granular products like grains and pellets.

- Gravity Vibration Fillers: Use vibration to settle products into containers.

- Belt Feeders: Utilize a belt to transport and fill granules.

4. Volumetric Filling Machines: Measure the volume of the product before filling.

- Piston Volumetric Fillers: Utilize pistons to measure and dispense.

- Cup Volumetric Fillers: Pre-calibrated measuring cups ensure consistency.

5. Weigh Fillers: Focus on the weight of the product being filled.

- Tabletop Weigh Fillers: Compact, suitable for small batches.

- Multi-Head Weigh Fillers: Multiple heads for high-speed, high-precision filling.

6. Aseptic Fillers: Used in sterile environments to fill products like pharmaceuticals.

- Aseptic Liquid Fillers: Maintain sterility throughout the process.

- Aseptic Powder Fillers: Ensure powders remain uncontaminated.

7. Pouch Fillers: Specifically designed for filling pouches.

- Horizontal Form-Fill-Seal (HFFS): Forms pouches horizontally and fills them.

- Vertical Form-Fill-Seal (VFFS): Forms pouches vertically before filling.

8. Bagging Machines: For filling bags with products ranging from powders to granules.

- Open-Mouth Bagging Machines: For pre-formed bags.

Custom Manufacturing Options for container filling equipment

Custom manufacturing options for container filling equipment can substantially enhance efficiency, precision, and adaptation to specific operational requirements. Here are several key options:

1. Container Types and Sizes: Custom equipment can be designed to accommodate a wide range of container types—bottles, jars, cans, bags, or custom shapes—and sizes, from tiny vials to large drums. This flexibility is essential for businesses with diverse product lines.

2. Filling Methods: Depending on the product, custom equipment can incorporate various filling methods such as volumetric, gravimetric, auger, or piston fillers. For instance, liquid products might use gravity or pump fillers, while powders could require auger or vibratory fillers.

3. Materials of Construction: Equipment can be tailored with specific materials like stainless steel, aluminum, or even specialized alloys to meet hygiene standards, resistance to corrosion, or specific industry regulations, such as those in food, pharmaceuticals, or chemicals.

4. Automation and Integration: Custom solutions can include varying degrees of automation, from semi-automatic to fully automatic systems. Integration with other machinery, such as cappers, labelers, or conveyors, can streamline the entire production line, enhancing throughput and reducing labor costs.

5. Precision and Quality Control: Incorporating advanced technologies like vision systems, weight checks, and feedback loops ensures consistent fill levels and quality control, essential for industries with strict compliance requirements.

6. Environment Adaptation: Custom equipment can be designed to operate in specific environments, such as cleanrooms or explosion-proof areas, making them suitable for sensitive or hazardous materials.

7. Modular and Scalable Design: A modular approach allows for future scalability, enabling businesses to adapt to increasing production demands without significant overhauls.

By opting for customized container filling equipment, manufacturers can achieve enhanced operational efficiency, product consistency, and compliance with industry standards, ultimately leading to improved profitability and customer satisfaction.

List Quality Control and The Manufacturing Process of "container filling equipment"

Quality Control in Container Filling Equipment

1. Design Verification:

- Conduct rigorous design reviews.

- Perform simulations to ensure the design meets operational demands.

2. Supplier Quality Management:

- Use certified suppliers for parts and materials.

- Perform incoming inspections for key components.

3. In-Process Inspections:

- Regular inspections during assembly.

- Monitor weld quality, alignment, and functional testing.

4. Calibration:

- Routine calibration of sensors, flow meters, and load cells.

- Use traceable standards for calibration processes.

5. Final Inspection & Testing:

- Comprehensive equipment testing including leak testing, cycle testing, and smooth operation.

- Verify all safety features and compliance with relevant regulations.

6. Documentation:

- Maintain detailed records of all inspections and test results.

- Ensure traceability from raw materials to final product shipment.

Manufacturing Process of Container Filling Equipment

1. Design & Prototyping:

- Develop CAD models based on user requirements.

- Create prototypes for functional and structural validation.

2. Material Procurement:

- Source high-quality materials such as stainless steel and food-grade plastics.

- Work with reliable suppliers to ensure material consistency.

3. Fabrication:

- Use CNC machining, laser cutting, and welding to create parts.

- Employ precision engineering to ensure parts meet design specifications.

4. Assembly:

- Assemble components in a clean, controlled environment.

- Use specialized tools and equipment for accurate assembly.

5. Automation & Integration:

- Install PLC systems, sensors, and actuators.

- Program control systems to manage filling operations and ensure efficiency.

6. Quality Assurance:

- Conduct in-depth testing including dry runs and initial fill cycles.

- Check for mechanical and electrical integrity.

7. Packaging & Shipping:

- Securely package the equipment to prevent damage during transit.

- Include comprehensive user manuals and maintenance documentation.

8. Installation & Training:

- Offer on-site installation and setup.

- Provide training for operators and maintenance staff.

How to use "container filling equipment"

Using container filling equipment involves several key steps to ensure accurate and efficient filling of containers with various types of products, ranging from liquids to granulated substances. Here’s a concise guide:

1. Preparation:

- Safety First: Wear appropriate protective equipment and understand the safety guidelines related to the machine and the material being handled.

- Machine Setup: Place the filling equipment on a stable surface. Connect it to the necessary power and/or air supply.

2. Calibration:

- Adjust Settings: Depending on the type of product and container, adjust the filling volume, speed, and nozzle diameter. This can usually be done using the machine's control panel.

- Test Run: Run a few test fillings to calibrate the machine precisely. Ensure the fill levels are consistent and adjust if necessary.

3. Filling Process:

- Loading Product: Pour or pump the product into the machine's reservoir or hopper.

- Positioning Containers: Place empty containers onto the filling platform or conveyor belt, ensuring they are properly aligned under the nozzles.

- Start Filling: Activate the machine to begin the filling process. The equipment will dispense the predetermined amount of product into each container.

4. Monitoring:

- Supervision: Continuously monitor the filling process to ensure everything runs smoothly. Watch for issues such as misalignment or inconsistent fills.

- Adjustments: Make any necessary adjustments on the fly to maintain accuracy and efficiency.

5. Post-Operation:

- Shutdown: Turn off the machinery according to the manual's instructions.

- Cleaning: Clean the equipment thoroughly to avoid contamination and ensure it’s ready for the next use. Follow specific cleaning procedures based on the product type.

6. Maintenance:

- Regular Checks: Perform routine maintenance as recommended by the manufacturer to keep the equipment in optimal working condition.

By following these steps, you'll ensure that your container filling equipment operates effectively and efficiently, maintaining product consistency and reducing waste.

List Properties and Terms of "container filling equipment"

Container Filling Equipment: Properties and Terms

1. Accuracy: Precision in measuring and dispensing exact quantities of product into containers, minimizing wastage and ensuring consistency.

2. Speed: The rate at which the machine can fill containers, critical for high-volume production environments.

3. Versatility: Ability to handle various container sizes, shapes, and materials, enhancing flexibility in production.

4. Ease of Use: User-friendly interface and controls for simplified operation and reduced training time.

5. Maintenance: Ease of cleaning and servicing, vital for minimizing downtime and ensuring hygiene, especially in food and pharmaceutical industries.

6. Durability: Construction from high-quality materials that resist wear and tear, ensuring long-term reliability.

7. Automation: Integration with automated systems for conveyor belts, capping, labeling, and packaging to streamline the production process.

8. Scalability: Adaptability to scale production up or down based on demand, providing operational flexibility.

Key Terms

1. Nozzle: The component that dispenses the product into the container, can be single or multiple.

2. Flow Meter: Device that measures the volume or mass of the liquid passing through it, ensuring precision.

3. Piston Filler: Uses a piston to draw and dispense product, suitable for viscous liquids.

4. Gravity Filler: Relies on gravitational force to fill containers, ideal for low-viscosity liquids.

5. Pump Filler: Utilizes pumps to transfer product into containers, effective for a wide range of liquid viscosities.

6. Overflow Filler: Ensures containers are filled to the same visual level, beneficial for transparent packaging.

7. Positive Displacement: Filling method that dispenses specific volume by partitioning product through gears or rotary lobes.

8. Clean-in-Place (CIP): Automated cleaning system without disassembly, crucial for hygiene compliance in regulated industries.

9. Bulk Supply Tank: Reservoir that holds the product to be dispensed, connected to the filling machine.

10. PLC (Programmable Logic Controller): Provides precise control over filling operations, enhancing automation and customization.

11. Conveyor System: Mechanized belts that transport containers through the filling process stages efficiently.

12. Capping System: Mechanism that seals containers post-filling to ensure product integrity.

List The Evolution history of "container filling equipment"

The evolution of container filling equipment has been marked by significant advancements driven by technological innovations and increasing demands for efficiency and precision.

Early Manual Methods (Pre-1800s)

Container filling began with manual methods, utilizing basic tools to fill containers, which was labor-intensive and inconsistent.

The Industrial Revolution (1800s)

With the Industrial Revolution, rudimentary mechanical fillers were developed to improve speed and consistency. Simple gravity fillers began to replace manual methods, leveraging the gravitational force to fill containers more efficiently.

Early 20th Century: Rise of Automation

The early 1900s saw the advent of semi-automatic filling machines, enabling higher volumes of production. Compressors and vacuum systems were incorporated, enhancing the capabilities for handling various types of liquids.

Mid 20th Century: Diversification and Precision

By the mid-20th century, filling technologies diversified—developing piston fillers, rotary fillers, and auger fillers to handle different product consistencies. This period also introduced the use of programmable logic controllers (PLCs), significantly improving precision and reliability.

Late 20th Century: Integration and Computerization

From the 1980s onwards, computerization revolutionized container filling equipment. Advanced automation allowed for seamless integration with packaging lines, improved control systems, and enhanced production monitoring through computer interfaces.

Early 21st Century: Innovations and Sustainability

The early 2000s brought about innovations in servo-driven fillers, which offered unparalleled accuracy and adaptability for various container types and fill volumes. Emphasis on sustainability led to developments in energy-efficient systems and reduced waste.

Current Trends: Smart Systems and IoT

Today, container filling equipment continues to evolve through the integration of Smart Systems and the Internet of Things (IoT). These advancements facilitate real-time monitoring, predictive maintenance, and unprecedented levels of precision and efficiency.

The ongoing advancements suggest a future where autonomous systems and artificial intelligence will play a major role, further optimizing the filling processes in terms of speed, consistency, and sustainability.

Each era of development has built upon the previous, creating a diverse and highly sophisticated landscape for container filling technology today.

How to Select a Reliable container filling equipment

Selecting reliable container filling equipment is crucial for efficiency and accuracy in your production process. Here are key factors to consider:

1. Production Requirements: Assess the specific needs of your production line, including speed, volume, and precision. Choose equipment that can meet your expected throughput and handle your product's characteristics (e.g., viscosity, particulate matter).

2. Versatility: Opt for equipment that can handle different container sizes and types if you have a diverse range of products. This flexibility will minimize the need for multiple machines, saving space and costs.

3. Accuracy and Consistency: Reliable equipment should consistently fill containers to the exact volume or weight, reducing product waste and ensuring quality control. Look for features like automated adjustments to maintain accuracy.

4. Ease of Operation and Maintenance: User-friendly machines with straightforward interfaces and clear instructions will reduce the learning curve for operators. Also, consider the ease of cleaning and maintenance to minimize downtime.

5. Material Compatibility: Ensure the equipment's construction materials are compatible with your product to avoid contamination or corrosion. Stainless steel is often preferred for its durability and hygiene properties.

6. Supplier Reputation and Support: Choose reputable suppliers with strong track records for reliability and customer service. Check reviews and seek recommendations. Ensure they offer robust after-sales support, including training, spare parts availability, and technical assistance.

7. Compliance and Certification: Ensure the equipment meets relevant industry standards and certifications (e.g., ISO, FDA) to guarantee safety and quality.

8. Cost vs. Value: While cost is important, consider the overall value, including durability, efficiency, and support. Investing in higher-quality equipment upfront can save costs in the long run by reducing downtime and maintenance needs.

By thoroughly evaluating these factors, you can select reliable container filling equipment tailored to your production needs, ensuring efficiency and quality in your operations.

List "container filling equipment" FAQ

Container Filling Equipment FAQ

-

What types of container filling equipment are available?

There are various types of container filling equipment including gravity fillers, pump fillers, piston fillers, and overflow fillers. Each type is suited to different kinds of products and containers. -

What industries use container filling equipment?

Industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and automotive utilize container filling equipment. -

How do I choose the right filling machine for my application?

The choice depends on the product's viscosity, the type of container, production speed, and accuracy requirements. Consulting with equipment manufacturers can help identify the best option. -

Can container filling equipment handle different types of containers?

Yes, many filling machines are versatile and can be adjusted to accommodate various container shapes and sizes. -

What is the maintenance involved with filling equipment?

Regular cleaning, inspection, and replacement of worn parts are crucial to ensuring longevity and optimal performance. Some machines have CIP (Clean-In-Place) systems for easier maintenance. -

How accurate are these machines in filling containers?

Modern filling machines are highly accurate, often achieving fill volumes within ±0.5% of the target value. The level of accuracy can vary based on the type and quality of the machine. -

Are there automatic and semi-automatic options available?

Yes, filling machines come in both automatic and semi-automatic models. Automatic machines offer higher speeds and efficiency, while semi-automatic machines provide flexibility and lower cost. -

What safety features are included in container filling equipment?

Safety features may include emergency stop buttons, protective guards, and automated shutdowns in case of a malfunction. -

How is container filling equipment integrated into an existing production line?

Equipment manufacturers often offer customization and integration services to ensure seamless fit and operation within existing production lines. -

What are the costs associated with container filling machines?

Costs vary based on machine type, features, and capacity. Entry-level machines start at a few thousand dollars, while high-end, fully automated systems can cost significantly more.

Top 10 FAQ with answer about container filling equipment for Buyer Sourcing from China

Certainly! Here are the top 10 frequently asked questions (FAQs) about sourcing container filling equipment from China, along with concise answers:

-

What types of container filling equipment are available?

- China manufactures a variety of container filling equipment including liquid fillers, powder fillers, granule fillers, and paste fillers. Options vary from fully automated systems to semi-automated and manual machines.

-

How can I verify the quality of the equipment?

- Verify quality through factory audits, requesting certifications (such as CE, ISO), and obtaining references from past clients. Sample testing of equipment can also provide insight into quality.

-

What is the typical lead time for delivery?

- Lead times can vary but generally range from 4 to 12 weeks depending on the complexity of the equipment and the manufacturer’s current production schedule.

-

Are there customization options available?

- Yes, most Chinese manufacturers offer customization to meet specific requirements, such as different container sizes, filling capacities, and additional features like mixing or sealing options.

-

What are the payment terms?

- Common terms include 30% advance payment upon order confirmation and 70% before shipment. Terms may vary, and some suppliers might accept letters of credit (L/C).

-

How much does shipping cost?

- Shipping costs depend on factors like the size and weight of the equipment, shipping method (air or sea), and destination. Obtain quotes from freight forwarders for precise estimates.

-

What after-sales support is provided?

- After-sales support commonly includes spare parts, remote technical assistance, and maintenance guides. Some manufacturers may offer on-site installation and training for an additional fee.

-

Can the equipment meet international standards?

- Many Chinese manufacturers build equipment to meet international standards, including CE for Europe, UL for the USA, or other relevant certifications.

-

What is the warranty period?

- Warranty periods typically range from one to two years, varying by manufacturer. Be sure to clarify specifics regarding what is covered under the warranty.

-

How can I find a reliable supplier?

- Use online sourcing platforms like Alibaba, attend trade shows, consult industry contacts, and read reviews. Always conduct thorough research and vet potential suppliers thoroughly.

These concise answers should help buyers in making informed decisions when sourcing container filling equipment from China.