List Technical Parameters of “container sealing machine”

A container sealing machine is a type of industrial equipment designed to seal and close containers securely. The machine can seal various types of containers, including cans, bottles, jars, and plastic containers, among others.

The technical parameters of a container sealing machine are essential in determining the machine’s performance and capabilities. Some of the critical technical parameters of a container sealing machine include:

1. Sealing Height: The machine’s sealing height refers to the maximum height that the machine can seal a container. This parameter is essential, especially for sealing tall containers.

2. Sealing Diameter: This parameter refers to the maximum diameter of the container that the machine can seal. It is essential to choose a machine with a sealing diameter that can accommodate the size of your containers.

3. Sealing Speed: The sealing speed is the number of containers that the machine can seal within a given time. The machine’s sealing speed is a critical parameter, especially for high-volume production lines that require fast and efficient sealing.

4. Power Consumption: The machine’s power consumption is essential to consider, as it determines the energy requirements and related costs. A lower power consumption machine is usually considered more cost-effective.

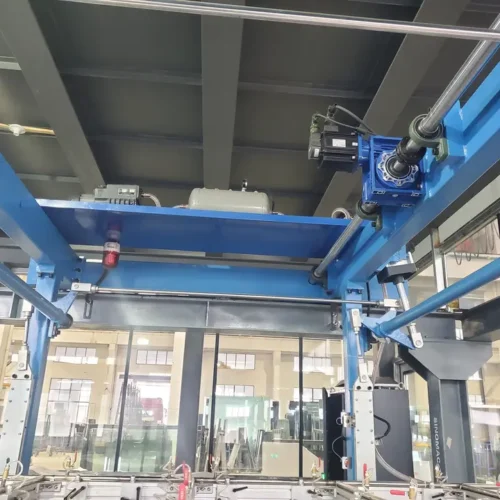

5. Machine Size: The size of the container sealing machine is an important consideration, especially for small production spaces. The machine’s size should correspond to the available space in the production facility.

6. Air Pressure: The air pressure requirement is an important technical parameter, especially for pneumatic-based container sealing machines. The required air pressure should be within the available supply in the production facility.

7. Material Compatibility: The machine’s material compatibility parameter refers to the type of containers that the machine can seal efficiently and effectively. It is essential to choose a machine that can handle the materials and shapes of containers that you seal.

8. Sealing Type: The sealing type refers to the method used by the machine to seal the containers. The sealing type can be induction, heat sealing, or vacuum sealing, among others. It is important to choose a sealing type that is compatible with your products and production requirements.

Overall, choosing a container sealing machine requires assessing the technical parameters carefully to ensure that it is suitable for your production needs. The technical parameters listed above are just some of the critical factors you should consider when selecting a high-quality machine.

List Product features of “container sealing machine”

A container sealing machine is an essential piece of equipment for packing products safely, securely, and with ease. It is perfect for packaging and sealing a variety of products such as beverages, foods, pharmaceuticals, and cosmetics.

1. Type of Sealing: The container sealing machine is capable of performing various types of sealing, such as induction, cap, and capping.

2. Capacity: The machine has the capacity to seal numerous containers that come in different sizes and shapes.

3. Power and Efficiency: The power consumption of the machine is relatively low, and it is energy-efficient, making it ideal for both small and large-scale productions.

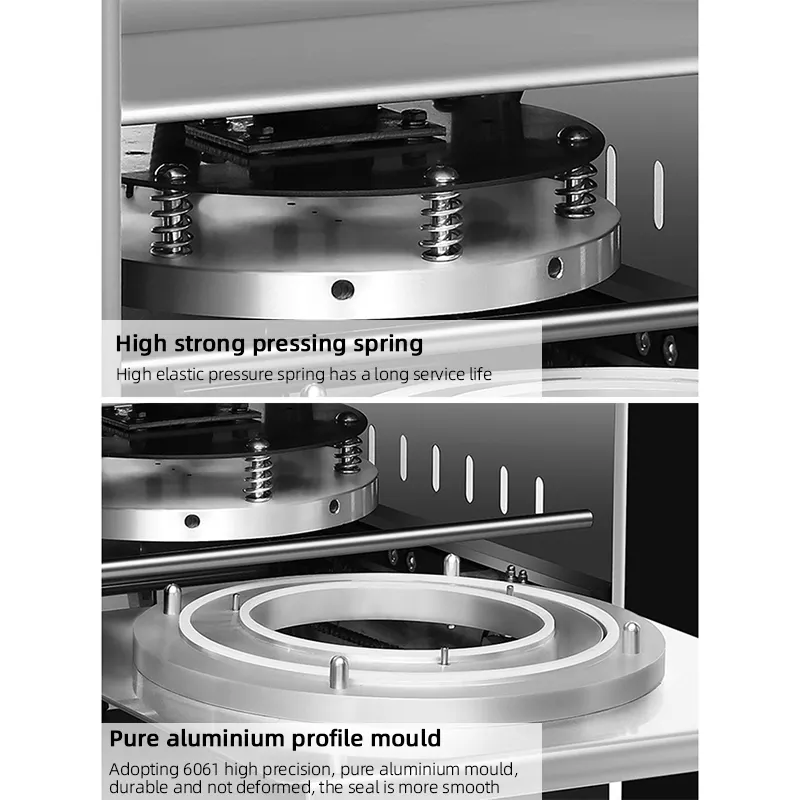

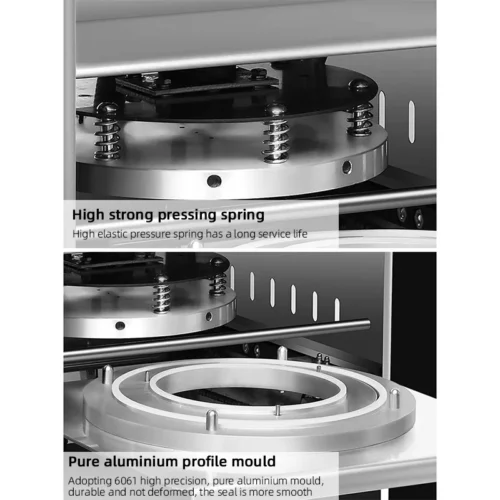

4. Durability: The machine is made of high-quality materials like stainless steel, making it sturdy and long-lasting, with minimal maintenance costs.

5. User-friendly: The machine is simple and easy to operate, even for individuals new to the packaging and sealing industry.

6. Safety Standards: The container sealing machine meets all safety standards and regulations, ensuring that the product packaging is safe for consumers.

7. Customizable Parameters: The user can customize the sealing temperature, time, and pressure, according to the needs and requirements of the product, making the machine versatile.

8. Compatibility and Versatility: The machine is compatible with different types of containers, including bottles, jars, pots, and tubes, and can seal a wide range of materials such as glass, plastic, and metal.

9. Speed: The container sealing machine can be configured to seal products at a high speed of up to 300 containers per minute, ensuring that the production process is efficient and timely.

10. Cost-Effective: The machine is cost-effective and offers an excellent return on investment since it reduces labor costs and increases productivity.

Overall, the container sealing machine is an essential piece of equipment for ensuring the safe and efficient packaging of products. Its user-friendly nature, durability, versatility, and customizable parameters, make it a reliable and valuable investment for both small and large-scale production units.

List Application of “container sealing machine”

Container sealing machines are commonly used in various industries to effectively seal containers, whether for the purpose of storage, transportation, or sale. Here are some of the most common applications of container sealing machines:

1. Food and Beverage Industry: One of the most important applications of container sealing machines is in the food and beverage industry. These machines are commonly used to seal cans, jars, and other containers for various food items, such as sauces, jams, pickles, and juices. The hermetic sealing of containers is essential to preserve the freshness, taste, and quality of the food, protecting it from contamination and oxidation.

2. Pharmaceutical Industry: The pharmaceutical industry is another major application of container sealing machines. These machines are used to seal vials, ampoules, and other containers that hold medications or vaccines. Ensuring that the containers are completely sealed is critical to maintaining the potency and safety of the drugs and preventing contamination.

3. Cosmetics Industry: The cosmetics industry also uses container sealing machines extensively. These machines are used to seal tubes, bottles, and jars that hold a variety of cosmetic products, such as creams, lotions, and serums. The airtight sealing of these containers helps to prevent oxidation, spoilage, and microbe growth, ensuring the longevity and quality of the products.

4. Chemical Industry: In the chemical industry, container sealing machines are used to seal containers that store hazardous chemicals or substances. The machines ensure that the containers are securely sealed and leak-proof, minimizing the risk of spills and accidents during transportation or storage.

5. Automotive Industry: Container sealing machines are also used in the automotive industry, particularly for sealing containers that hold fluids, such as oil, coolant, and brake fluid. High-precision sealing is necessary to prevent leaks that can damage the vehicle and compromise its performance.

In conclusion, container sealing machines play a vital role in various industries where the hermetic sealing of containers is essential for the preservation and safety of the contained goods or substances. These machines are used in the food, pharmaceutical, cosmetics, chemical, and automotive industries, among others, to ensure that the containers are securely sealed and protected from contamination, oxidation, and damage.

List Various Types of “container sealing machine”

1. Induction sealing machines: These machines use electromagnetic induction to create heat to seal the container. The special sealing material on the cap of the container is heated by the electromagnetic field generated by the machine and it fuses to the container to provide a secure seal.

2. Capping machines: These machines are used to apply caps or closures to containers by screwing them on. They can be used for various types of containers, including bottles, jars and vials.

3. Band sealing machines: These machines use heat-sealing technology to create a seal on the container using continuous thermal band. They are used for flexible pouches, bags and other packaging materials.

4. Impulse sealing machines: These machines use heat to create a seal on the container using a heating element that is heated with an electric current. They are commonly used for plastic bags, films and tubing.

5. Vacuum sealing machines: These machines are used to remove air from the container before sealing. They are used to preserve food and other perishable items for longer periods by preventing oxidation or spoilage.

6. Pressure sealing machines: These machines apply pressure to the container to create a seal. They are used for packaging materials that are not heat-sealable or to create higher-integrity seals on some materials.

7. Ultrasonic sealing machines: These machines use ultrasonic waves to create a seal on the container. They are used for various packaging materials, including plastic and aluminum foils and films.

8. Sleeve sealing machines: These machines are used to apply sleeves or shrink labels to containers before they are sealed. They can be used for various types of containers, including bottles, cans and jars.

Container sealing machines are essential in various industries, including food and beverage, pharmaceuticals and cosmetics. They provide a secure seal on containers to ensure the products inside are safe from contamination, leakage or spoilage.

List The Process of “container sealing machine”

The container sealing machine is a device used to seal containers to prevent spillage and contamination. These machines come with different sizes and specifications, depending on the container’s size and the industry’s needs. Here is the process of using a container sealing machine:

1. Preparing the container: Before sealing the container, it needs to be clean and free from any debris. If the container is dirty, it needs to be washed and dried properly. The sealing machine will not work correctly if there is anything on the rim of the container.

2. Filling the container: Once the container is clean, it needs to be filled with the product being sealed. The filling process can be done manually or with an automated machine, depending on the volume of the product needed.

3. Placing the cap: Once the container is full, the cap needs to be placed on the container. The cap can be a screw cap, snap-on cap, or any other kind of cap, depending on the container’s size and the industry’s requirements.

4. Sealing the container: The container sealing machine now comes into play. The container is placed on the sealing machine, and the machine’s sensors will locate the cap’s position. The machine then applies the required amount of pressure to seal the cap onto the container.

5. Quality check: Once the sealing process is complete, the container is checked for leaks and other issues. If there are any issues, the machine will automatically reject the container and halt production until the problem is fixed.

6. Packaging: After passing the quality check, the container is ready for packaging and distribution. The containers will be packed into cartons or boxes and stored accordingly.

In conclusion, the container sealing machine is an integral part of various industries, including the food and beverage, pharmaceutical, and cosmetics industries. With the advancement in technology, different types of machines are available to meet specific sealing requirements.

How to use “container sealing machine”

A container sealing machine is a piece of equipment used to seal various types of containers such as plastic bottles, jars, and cans. This machine is commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics to ensure that products are secure and protected during transport and storage.

To use a container sealing machine, you need to have the right type of container that fits the machine specifications. You also need to ensure that the machine is properly set up according to the manufacturer’s instructions. Some of the common steps involved include:

1. Adjusting the machine height and rollers to the correct position for the container size and shape.

2. Turning on the power source and adjusting the temperature settings to the recommended level for the type of seal to be used.

3. Filling the container with the desired product and placing it on the machine’s platform.

4. Activating the machine to start the sealing process by pushing the start button.

5. Removing the sealed container from the machine and inspecting it to ensure that the seal is tight and secure.

6. Cleaning the machine after use to maintain hygiene and prevent contamination.

It is also important to note that different types of containers may require a different type of seal, such as a plastic or metal cap, foil seal or induction seal. Therefore, it is important to follow the manufacturer’s instructions and recommendations for the type of seal to be used for various container types.

Overall, using a container sealing machine requires careful attention to detail and adherence to safety and hygiene practices. By following the recommended steps and procedures, you can ensure that your products are sealed properly and are protected during transport and storage.

List Properties of “container sealing machine”

A container sealing machine is a piece of equipment that is used to effectively and efficiently seal a variety of containers. The machine can seal containers of different sizes, making it a versatile piece of equipment that can be used in different industries. The following are some of the properties of a container sealing machine:

1. Material: The primary material used to manufacture a container sealing machine is stainless steel, a material that is durable, resistant to rust and corrosion, easy to clean, and hygienic.

2. Design: A typical container sealing machine features a compact and user-friendly design that makes it easy to operate, maintain, and clean. It comes with a control panel that serves as a user interface and allows operators to set the sealing time, temperature, and other parameters.

3. Sealing Mode: A container sealing machine can operate in different sealing modes depending on the type of container being sealed, the sealing material used, and the required level of sealing. The most common sealing modes include impulse sealing, continuous sealing, and hot-air sealing.

4. Capacity: The capacity of a container sealing machine refers to the number and size of containers it can seal in a given time. The machine’s capacity is determined by its sealing width and speed, and it can range from a few containers per minute to hundreds, depending on the type and size of the machine.

5. Versatility: A container sealing machine is versatile and can be used to seal containers made of different materials, including plastic, glass, and metal. It can also be used to seal different types of containers, including jars, bottles, cans, and pouches.

6. Safety Features: A container sealing machine comes with safety features to protect the operator and prevent accidents. The features may include an emergency stop button, automatic shut-off, and temperature control to prevent overheating.

7. Maintenance: A container sealing machine is designed to be easy to maintain. Regular maintenance involves cleaning, lubrication, and replacement of worn-out parts. The machine’s user manual provides instructions on how to maintain and replace parts.

In conclusion, a container sealing machine is an essential piece of equipment for businesses that involve packaging products in containers. It is reliable, efficient, and versatile, and can help increase productivity and reduce operational costs over time.

List “container sealing machine” FAQ

1. What is a container sealing machine?

A container sealing machine is a specialized piece of equipment that is used to seal various types of containers such as bottles, cans, jars, and pouches.

2. What are the benefits of using a container sealing machine?

Using a container sealing machine can increase productivity and efficiency in packaging operations. It can also help to ensure consistent and reliable seal quality, prevent contamination, and extend the shelf-life of products.

3. What types of containers can be sealed using a container sealing machine?

A container sealing machine can seal a wide variety of containers made of different materials such as plastic, glass, metal, and paper.

4. How does a container sealing machine work?

A container sealing machine typically applies heat, pressure, or a combination of both to melt the sealing material and form a seal. The sealing material could be a foil or film material that is applied to the container using heat, pressure, adhesive, or ultrasonic waves.

5. What are some of the factors that affect the sealing quality of a container sealing machine?

The sealing quality of a container sealing machine can be affected by a number of factors such as temperature, pressure, sealing material, container shape and size, and the condition of the sealing components.

6. Are container sealing machines easy to operate?

Most container sealing machines are designed to be user-friendly and require minimal training to operate. However, it’s important to read and follow the manufacturer’s instructions for safety and optimal performance.

7. What is the maintenance schedule for a container sealing machine?

The maintenance schedule for a container sealing machine varies depending on the model and usage. Regular cleaning and inspection of the sealing components, electrical and mechanical parts, and safety devices are recommended to ensure the machine operates properly and safely.

8. Can container sealing machines be customized to meet specific needs?

Yes, many manufacturers offer customized solutions to meet specific requirements such as container type, sealing material, production volume, and automation level. It’s important to discuss your needs with the manufacturer or supplier to determine the best solution for your operation.