List Technical Parameters of “crown capper”

A crown capper, also known as a bottle capper, is a machine used to seal bottles or containers with metal caps called crowns. The technical parameters of a crown capper include:

1. Capacity: The number of bottles that can be sealed per minute.

2. Bottle size range: The minimum and maximum bottle size that can be sealed on the machine.

3. Crown size range: The minimum and maximum crown size that can be used on the machine.

4. Material: The type of material used to manufacture the machine and its parts.

5. Power consumption: The amount of power required to operate the machine and its associated electrical components.

6. Noise level: The measure of sound generated by the machine during operation, usually expressed in decibels (dB).

7. Dimensions: The physical size of the machine, including length, width, and height, as well as its weight.

8. Operation mode: Whether the machine is manual, semi-automatic, or fully automatic.

9. Control system: The type of control system used to operate the machine and monitor its performance, including sensors, switches, and programmable logic controllers (PLCs).

10. Safety features: The presence of safety devices such as emergency stops, guarding, and warning labels to prevent accidents during operation.

These technical parameters play a critical role in determining the type of crown capper that is best suited for a particular application and environment. A highly automated crown capper, for instance, may be ideal for a high-volume bottling line, whereas a small manual capper may be more practical for a small craft brewery. Ultimately, selecting the right crown capper requires careful consideration of its technical specifications and the specific needs of the operation.

List Product features of “crown capper”

A crown capper is a device that is primarily used to seal the top of a bottle using a crown cap. These caps are typically made of metal and are used to seal bottles of beer, soda, and other carbonated beverages. Some of the essential features of a crown capper are:

1. Ease of use: Crown cappers are designed to be simple and easy to use. They typically require minimal effort to ensure that the crown cap is securely sealed onto the bottle.

2. Durability: The best crown cappers are made of durable materials that can withstand repeated use over time. This ensures that they offer long-term value and do not need to be replaced frequently.

3. Compatibility: Crown cappers are compatible with a wide range of bottle sizes and shapes. This means that they can be used for sealing beer bottles, soda bottles, and other types of containers.

4. Adjustable height: The top of the crown capper is typically adjustable, allowing users to adjust the height of the device to ensure that it fits securely onto the bottle.

5. Non-slip base: Most modern crown cappers feature a non-slip base that ensures that the device remains stable when it is in use. This reduces the risk of the capper slipping and potentially causing injury.

6. Portable: Many crown cappers are small and lightweight, making them portable and easy to use in a variety of settings.

7. Cost-effective: Crown cappers are relatively inexpensive, making them an affordable option for people who want to seal their own bottles at home.

Overall, crown cappers are simple, yet essential tools for anyone who bottles their own beer or soda. They are durable, easy to use, and offer a cost-effective way to create a secure, professional-looking seal on your bottles.

List Application of “crown capper”

The crown capper is a versatile tool used in various industries, including the beverage industry and home brewing. Crown cappers are essential in sealing bottles with metal crown caps. The crown capper is a cost-effective and efficient piece of equipment that saves time and reduces labor costs. Below are some applications of crown cappers:

1. Beverage industry: Crown cappers are widely used in the soft drink, beer, and cider industries to seal bottles. Beverage producers use crown cappers to seal the bottles with crown caps. This ensures that the bottles are airtight and the beverages maintain their quality and freshness.

2. Pharmaceutical industry: The pharmaceutical industry uses crown cappers to seal bottles that contain medication. The airtight seal prevents the medication from degrading and maintains its effectiveness for an extended period.

3. Home brewing: Crown cappers are essential in home brewing. They are used to seal bottles containing beer or other homemade alcoholic beverages. Home brewers use crown cappers to seal the bottles and keep the beer fresh and carbonated.

4. Chemical industry: Crown cappers can be used in the chemical industry to seal bottles containing chemicals. The airtight seal keeps the chemicals from evaporating or reacting with other substances.

5. Olive oil and vinegar industry: Producers of olive oil and vinegar use crown cappers to seal bottles containing their products. The airtight seal preserves the quality and flavor of the products.

In conclusion, crown cappers are essential in various industries that require sealing bottles with metal crown caps. They provide a cost-effective and efficient way to ensure that products remain fresh and of high quality. Crown cappers have a wide range of applications in the beverage, pharmaceutical, chemical, and olive oil and vinegar industries, as well as in home brewing.

List Various Types of “crown capper”

Crown capper is a device that is used to seal bottles, specifically those that use the crown cap closure. Crown caps are the ubiquitous metal caps that are used on beer and soda bottles, among others. Crown cappers come in various types, designed to meet different sealing requirements and to cater to different users’ needs. In this article, we will highlight some of the most common types of crown cappers.

1. Handheld Crown Cappers – These devices are small, portable tools that you hold in your hand and manually press down to seal the bottle. They are ideal for home users, small-scale craft brewers, and those who need to seal bottles quickly without the need for electricity.

2. Stationary Crown Cappers – These machines are more advanced than the handheld devices and are mostly used in commercial settings. They function by pressing the crown cap to the bottle neck and sealing it through a set of rollers that ensure a tight seal.

3. Bench-Top Crown Cappers – These machines operate similarly to the stationary crown cappers but are smaller and designed to be used on a benchtop to save space. They are suitable for small production runs and produce a consistent seal, ensuring that each bottle is sealed correctly.

4. Automatic Crown Cappers – These machines are fully automated and are the most advanced of all types of crown cappers. They can be used to seal thousands of bottles a day, making them ideal for large-scale beverage manufacturers.

In conclusion, crown cappers come in a variety of types designed to meet different sealing requirements and cater to different users’ needs. Nevertheless, regardless of the type you choose, it is essential to ensure that your crown capper is of good quality and is easy to use to guarantee consistent and efficient bottle sealing.

List The Process of “crown capper”

Crown capping is a process of sealing bottles with caps to preserve the contents from contamination and maintain the carbonation of drinks. The following steps are involved in the crown capping process:

1. Filling: First, the bottles are filled with the desired beverage, which can be anything from beer to soda. The filling process may vary according to the type of drink.

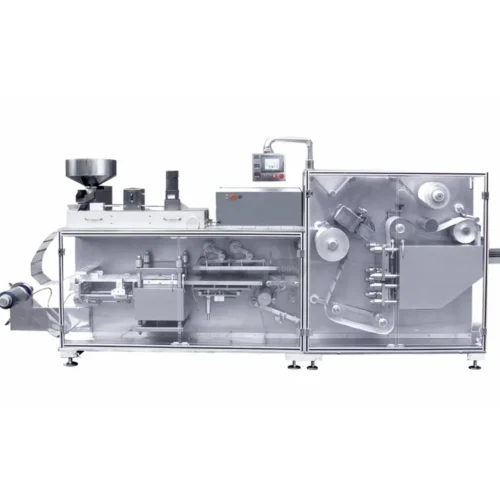

2. Crown capper: The crown capping machine is a semi-automatic machine that consists of three components: the bottle platform, the cap delivery system, and the cap crimping system.

3. Cap delivery: The crown capping machine automatically delivers caps to the platform above the bottles. A crown cap is a small, circular metal cap with serrated edges.

4. Crimping: The machine then presses the cap firmly onto the neck of the bottle, while simultaneously crimping the serrated edges of the crown cap onto the bottle lip. The crimping ensures that the cap stays firmly in place, creating an airtight seal.

5. Inspection: After the capping process is complete, the bottles are inspected to confirm that the caps are properly crimped and sealed. Any bottle with a faulty seal is removed from the production line.

6. Packaging: The finished bottles are then either packaged and shipped for distribution or sent to a labeling machine, where product information is printed onto the bottles.

Overall, the crown capping process is essential for preserving the quality of beverages by ensuring their freshness, carbonation and protecting them from external contaminants.

How to use “crown capper”

A crown capper is a tool that is used to seal bottles with crowns or caps. It is a simple device consisting of two parts – a base and a lever arm. Using a crown capper is easy; you simply need to follow these steps:

1. Sanitize the bottles: Make sure that the bottles you are using are clean and sanitized. This will ensure that there is nothing that will interfere with the capper or the seal.

2. Fill the bottles: Fill the bottles with the beverage or liquid you want to preserve.

3. Place the crowns/caps: Using a magnetic or similar holder, place the crowns on the top of the bottles. Make sure that they are centered and fitted properly.

4. Position the capper: Place the bottle in the capper’s base and adjust it so that the crown lines up with the capper’s jaws.

5. Use the capper: Press the lever arm downward, and the jaws of the capper will grip the crown firmly. Apply even pressure so that the crown is sealed tightly to the bottle.

6. Inspect the seals: After sealing all the bottles, inspect the seals to see if they are tightly closed and the crown attaches to the bottle neck. Adjust if necessary and store the bottles in a cool, dry place.

In conclusion, using a crown capper is an easy and simple process. Make sure to prepare and sanitize the bottles before use and adjust the capper properly, then apply even pressure to ensure a tight seal. Crown capper is a useful tool for anyone who wants to preserve liquids (often homemade beer, soda, or wine) in bottles.

List Properties of “crown capper”

A crown capper is a mechanical device used to seal bottles with crown caps. Some common properties of crown cappers are discussed below:

1. Construction: Crown cappers are commonly made of sturdy materials such as stainless steel or aluminum. The device features a base plate, a lever arm, a crimping head, and a crown cap holder.

2. Bottle Compatibility: Crown cappers are versatile tools that can be used to seal bottles of different sizes. They are commonly used to seal beer bottles, soda bottles, and other bottles that use crown caps. However, different sizes of capping heads are required to accommodate different bottles sizes.

3. Ease of Use: Crown cappers are usually very easy to use and do not require any prior experience or special training. The bottle is placed under the crimping head and the crown cap is secured onto the bottle neck. The lever arm is then pressed down to crimp the cap onto the bottle.

4. Durability: Crown cappers are built to last. They are typically made from high-quality materials that can withstand regular use and frequent cleaning. With proper maintenance, a well-constructed crown capper can last for years.

5. Efficiency: Crown cappers are designed to make the capping process quick and efficient. They can cap many bottles in a short amount of time, making them ideal for commercial use.

6. Portability: Crown cappers are relatively small and lightweight, making them easily portable. They can be used in different locations, which makes them suitable for small business owners.

7. Cost-Effective: Crown cappers are an affordable investment for anyone who bottles beverages. They can significantly reduce the cost of outsourcing the capping process, which make them ideal for start-up businesses.

In conclusion, crown cappers are efficient, affordable, and require little training to use. They are essential tools for anyone in the beverage industry.

List “crown capper” FAQ

1. What is a crown capper?

A crown capper is a device used for sealing bottles with crown caps, which involves crimping a metal cap over the bottle’s opening with an airtight seal.

2. What types of bottles can be capped with a crown capper?

A crown capper can be used on most glass and plastic bottles that have a standard crown cap size.

3. What is the process of using a crown capper?

The process starts by placing the crown cap on top of the bottle, and then positioning the bottle on the capper’s platform. The lever on the capper is then pressed down to crimp the cap over the bottle’s opening, creating a secure seal.

4. Can a crown capper be used for carbonated beverages?

Yes, a crown capper is suitable for sealing carbonated beverages. This is because the crown cap creates a tight seal preventing carbonation loss and maintaining carbonation over time.

5. How many bottles can be capped with one crown capper?

The number of bottles that can be capped with a single crown capper depends on the capper’s size and capacity. However, in general, most crown cappers can cap between 20 to 50 bottles per hour.

6. Can a crown capper be used for homebrewing?

Yes, a crown capper is a popular tool for homebrewers since they can use it to cap their beer bottles quickly and efficiently.

7. Is a crown capper expensive?

No, crown cappers are relatively inexpensive and can be purchased for a reasonable price, making them an affordable investment for homebrewers and small beverage manufacturers.

In conclusion, a crown capper is an essential device for sealing bottles with crown caps, suitable for use on most glass and plastic bottles of different sizes. It is easy to use, relatively inexpensive, and effective in maintaining carbonation in carbonated beverages, making it a popular tool for homebrewers and small beverage manufacturers alike.