Types and Applications

Glass bottle filling machines come in various models, each designed for specific applications:

- Beverage Industry: From carbonated drinks to fruit juices, these machines ensure precise filling, maintaining the beverage’s quality.

- Pharmaceuticals: Ensuring accurate dosage and maintaining sterility is crucial. Specialized machines cater to these requirements.

- Cosmetics: Perfumes, lotions, and other liquid cosmetics require precise filling, and these machines are up to the task.

- Chemicals: For chemicals, accuracy and safety are paramount. Machines designed for this industry come with additional safety features.

Production Process and Technology

The evolution of glass bottle filling machines has been marked by technological advancements:

- Evolution: From manual operations to fully automated systems, the journey has been about increasing efficiency and precision.

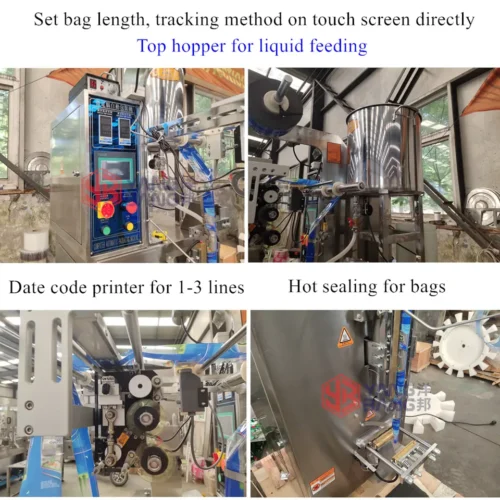

- Modern Innovations: Today’s machines come equipped with touch screens, PLC controls, and advanced sensors to ensure seamless operations.

- Sustainability: Energy-efficient designs and reduced water consumption are now standard features, reflecting the industry’s commitment to sustainability.

User Guide: Operating the Glass Bottle Filling Machine

Operating these machines requires a blend of technical knowledge and adherence to safety protocols:

- Step-by-step Instructions: From setting up the machine to the actual filling process, a detailed manual guides operators at every step.

- Safety Precautions: Ensuring that the machine is grounded, regularly checking for wear and tear, and keeping the workspace clean are some of the essential safety measures.

- Maintenance: Regular maintenance checks, cleaning, and timely replacement of worn-out parts ensure the machine’s longevity and efficiency.

International Buyers: Questions to Ask Chinese Suppliers

When sourcing from China, buyers should be diligent and ask pertinent questions:

- Authenticity: Can the supplier provide references or case studies from previous clients?

- Warranty: What does the warranty cover, and for how long?

- Customization: Can the machine be customized to meet specific requirements, and at what cost?

Pricing and Cost Analysis

Understanding the cost structure of glass bottle filling machines is essential for potential buyers. Several factors influence the final price:

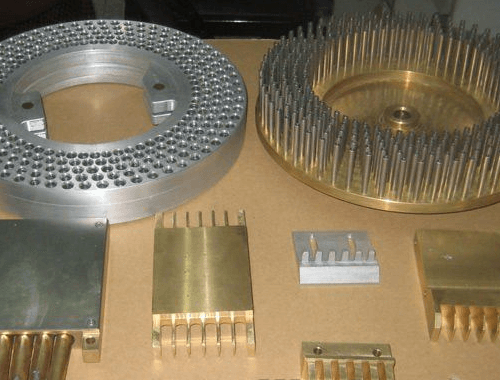

- Manufacturing Costs: This includes raw materials, labor, and overhead costs. Given the machine’s complexity, high-quality materials like stainless steel and advanced components can drive up the price.

- Technological Features: Machines equipped with advanced features like touch screens, PLC controls, and automation systems tend to be priced higher.

- Customization: Tailoring the machine to specific requirements can affect the cost. Features like increased capacity, specialized filling mechanisms, or additional safety measures can add to the price.

- Shipping and Import Duties: For international buyers, shipping costs and import duties can significantly impact the final cost.

- After-sales Service: Extended warranties, maintenance packages, and training programs can influence the machine’s price.

FAQ Tips

- Lifespan: Typically, with regular maintenance, a glass bottle filling machine can last for 10-15 years.

- Handling Different Bottles: Advanced machines come with adjustable settings to handle various bottle sizes and shapes.

- Optimal Operating Conditions: While these machines are designed to operate in diverse environments, it’s best to keep them in a clean, dry, and temperature-controlled space.

- Maintenance Frequency: Regular checks every six months and a comprehensive annual review are recommended.

- After-sales Support: PkgMach offers extensive after-sales support, including maintenance, spare parts, and training.

- Training Programs: Comprehensive training programs ensure that operators can efficiently handle the machine.

- Accuracy and Consistency: Advanced sensors and automation ensure precise filling, with a consistency rate of over 99%.

- Safety Features: Safety locks, emergency stop buttons, and overload protection are standard features.

- Integration with Production Lines: These machines are designed to integrate seamlessly with existing production lines.

- Energy Consumption: Modern machines are energy-efficient, with some models offering energy-saving modes for reduced consumption.

Why Choose PkgMach?

PkgMach stands out in the competitive market for several reasons:

- Tailored Solutions: Recognizing that each client has unique needs, PkgMach offers customized solutions, ensuring optimal results for every business.

- Extensive Product Range: Their vast product range caters to diverse industries, from honey packaging machines to auto wrapping machines.

- Reputation for Quality: PkgMach’s reputation as a quality manufacturer ensures that buyers are making a sound investment. Their rigorous quality control measures, expert team, and commitment to continuous improvement make them a preferred choice.

In conclusion, the glass bottle filling machine industry is vast and dynamic. With advancements in technology and increasing demand, the market is set to grow exponentially. For businesses looking to invest, understanding the product specifications, cost factors, and choosing a reliable supplier like PkgMach can make all the difference.