List Technical Parameters of “flour packing machine”

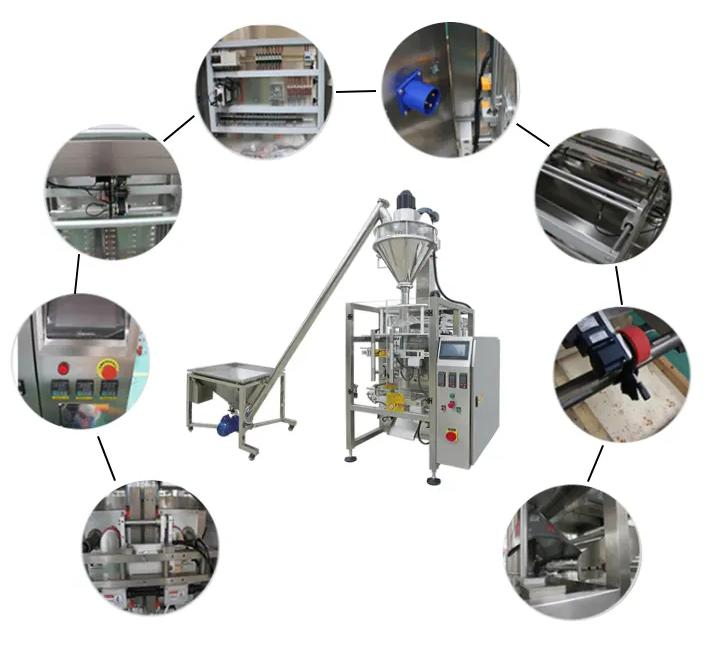

A flour packing machine is a highly specialized piece of equipment used to package flour products quickly and efficiently into bags for distribution to retail stores or commercial customers. Technical parameters define the specifications of the machine, including dimensions, power requirements, and operating capacity.

The following are some of the critical technical parameters of a flour packing machine:

1. Capacity: Flour packing machines come in various pack sizes, ranging from 5 kg to 50 kgs.

2. Accuracy: Flour packing machines need to operate with high accuracy since any variation, even slight, in weight can lead to product loss and customer dissatisfaction.

3. Power: Flour packing machines require stable and reliable power sources to operate. They typically require 220V, 50 Hz, three-phase power supply.

4. Packaging speed: Flour packing machines vary in packaging speed, with typical rates ranging from 5-8 bags per minute.

5. Bag material: The type of bag material used will depend on whether the flour is to be stored for short or long term. Most machines are designed to accommodate paper bags, polypropylene bags, and mesh bags.

6. Air supply: Flour packing machines often require a source of compressed air to operate the filling mechanism efficiently.

7. Dimensions: Flour packing machines come in different sizes, depending on their capacity and the space available in the production plant. A typical small flour packaging machine requires a floor area of about 2380mm x 980mm.

8. Control system: Flour packing machines have advanced control systems that regulate weight accuracy, bag filling speed, and air pressure. They may use touch-screen control panels or manual controls.

9. Maintenance: Flour packing machines must be regularly maintained to ensure their continual efficient operation. The machines require cleaning, greasing, and other regular servicing.

10. Safety features: Flour packing machines come with numerous safety features to prevent operator injury, including emergency stop buttons and safety guards.

In conclusion, the critical technical parameters of a flour packing machine are capacity, accuracy, power, packaging speed, bag material, air supply, dimensions, control system, maintenance, and safety features. These features ensure that the machine operates reliably and efficiently, and produces high-quality flour products for distribution to customers.

List Product features of “flour packing machine”

1. Automated: The flour packing machine features an automated system that is designed to package and seal flour quickly and efficiently.

2. High Capacity: The machine is designed to handle a high volume of flour, making it ideal for large scale production operations.

3. Accurate Packaging: The machine is calibrated to accurately measure and package flour in predetermined amounts, ensuring consistent quality and quantity of each bag.

4. Easy to Operate: The machine is simple to operate, with intuitive controls and easy-to-understand display panels.

5. Versatile: The machine is adaptable to a range of flour types and packaging sizes, allowing for flexibility in production processes.

6. Durable: The machine is built to withstand the rigours of continuous use, with high-quality components and sturdy construction.

7. Modern Design: The machine features a stylish, modern design that is both functional and aesthetically pleasing.

8. Safe and Hygienic: The machine is designed with safety and hygiene in mind, with easy-to-clean surfaces and safety guards to protect operators.

9. Energy Efficient: The machine is designed to be energy efficient, with minimal energy wastage and low running costs.

10. Cost Effective: The machine offers a cost-effective solution for packaging flour, with low maintenance costs and a high return on investment.

Overall, the flour packing machine is a reliable, efficient and versatile piece of equipment that is essential for any flour production operation. Its features make it an excellent choice for companies looking to improve their production processes, reduce waste and increase profitability.

List Application of “flour packing machine”

Flour packing machines are versatile machines that can be used for various applications in numerous industries. Here are some of the common applications of a flour packing machine:

1. Flour Mills: Flour packing machines are commonly used in flour mills to package different quantities of flour in bags. These machines have high-speed operations and can pack a large volume of flour in a short time.

2. Bakeries: Bakeries use flour packing machines to pack flour in bags for their daily use. These machines make it easy for bakeries to maintain hygiene and avoid contamination while packing flour.

3. Food Processing Industry: Flour packing machines are widely used in food processing industries to pack various types of flour, including wheat flour, corn flour, and rice flour. These machines can handle fine powder materials with ease and provide an efficient packaging solution for food manufacturers.

4. Retail Stores: Flour packing machines are also used in retail stores to pack different quantities of flour for customers. These machines are efficient, fast, and easy to use, allowing store owners to pack a large volume of flour in a short time.

5. Agricultural Sector: Flour packing machines are used in the agricultural sector to pack different types of flour, including animal feed, fertilizers, and seeds. These machines can handle loose materials and pack them into bags for easy transportation and storage.

6. Chemical Industry: Flour packing machines are also used in the chemical industry to pack powders, including cement, lime, and gypsum. These machines have a durable construction that can withstand harsh operating conditions.

Overall, flour packing machines have a wide range of applications and are beneficial to various industries that require fast and efficient packing solutions for their products. These machines not only increase production efficiency but also ensure that the packaged products are safe for human consumption.

List Various Types of “flour packing machine”

Flour packing machines are widely used in the food industry to pack various types of flour in different quantities. Below are some of the types of flour packing machines:

1. Automatic flour packing machines – These machines are fully automated and can pack flour in various sizes and quantities.

2. Semi-automatic flour packing machines – These machines require some manual intervention but are faster than manual machines.

3. Open mouth flour packing machines – These machines are designed to pack flour in open mouth bags of various sizes.

4. Valve flour packing machines – These machines are used to pack flour in valve bags that are more durable and can hold more weight.

5. Auger flour packing machines – These machines use an auger to move the flour from the hopper to the bag, making them ideal for packing fine powders.

6. Rotary flour packing machines – These machines use a rotary system to fill and seal the bags, making them ideal for high-volume packaging.

7. Vacuum flour packing machines – These machines use a vacuum system to pack flour into bags without any air, ensuring longer shelf life.

8. Weighing flour packing machines – These machines use a weighing system to measure and pack precise amounts of flour, making them ideal for high-precision packaging.

9. Bag-in-box flour packing machines – These machines are used to pack flour in a bag inside a box, providing more protection against damage during transportation.

In conclusion, flour packing machines are available in different types and sizes to suit different packaging requirements. They increase productivity, reduce labor costs, and minimize the risk of contamination, making them a valuable investment for flour producers.

List The Process of “flour packing machine”

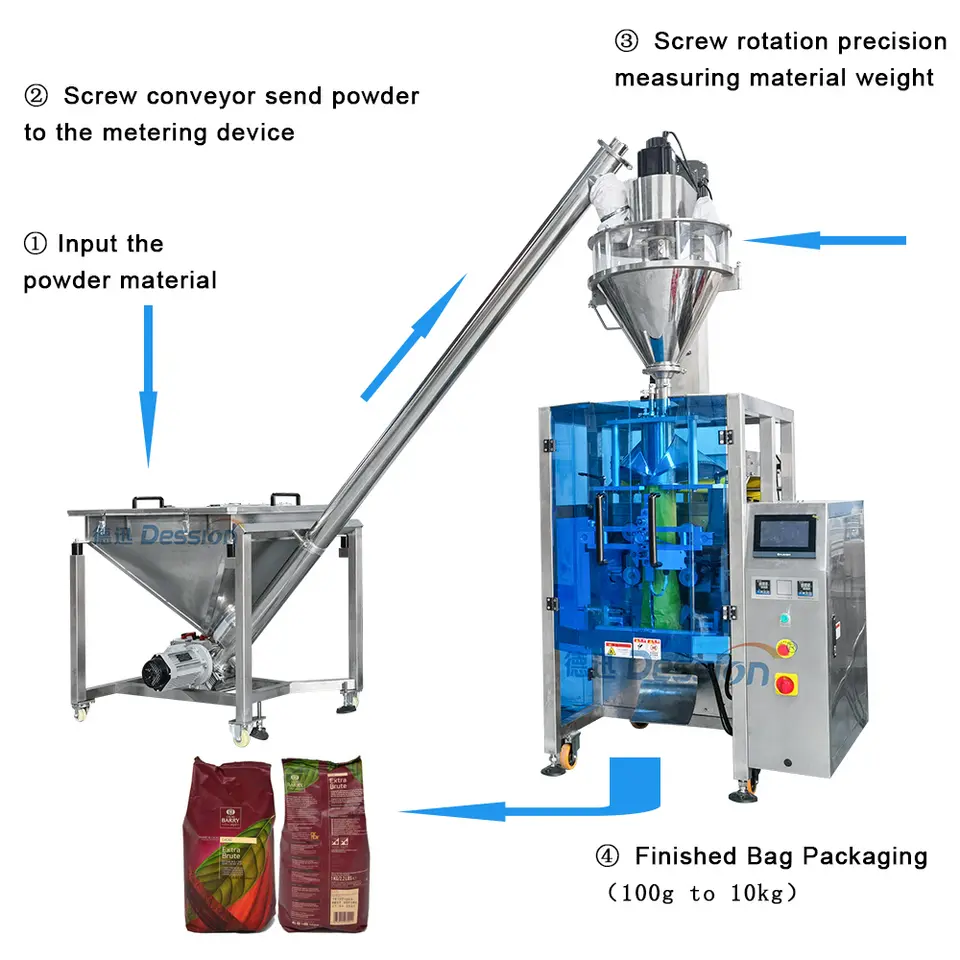

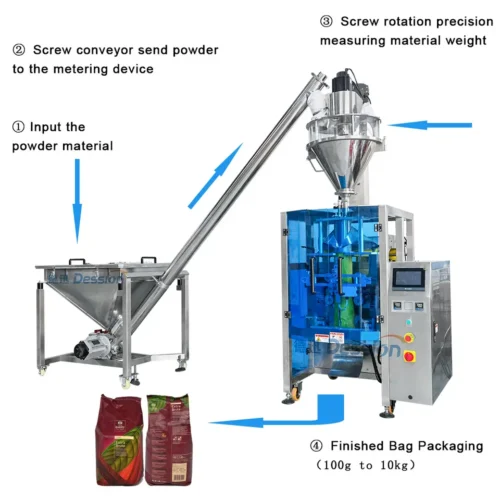

A flour packing machine is an automated piece of equipment designed to package flour into bags or containers accurately and efficiently. The process of flour packing using this machine can be broken down into the following stages:

1. Preparation: The flour packing machine is prepared by ensuring that all its components are clean, and the required amount of flour is present in the hopper. The machine’s settings and controls are then adjusted to suit the desired packaging specification.

2. Bag or container filling: Based on the specifications, the flour packing machine can fill bags or containers of different sizes and materials. The packaging material is usually loaded onto the machine, which feeds the flour into it, weighs it, and then seals it.

3. Sealing and labeling: Once the flour has been accurately weighed, the machine seals the packaging material using heat sealing technology. Labels are added to the package if required.

4. Quality control: Flour packing machines come equipped with advanced sensors and software that allow for real-time monitoring of the packing process. This way, any issues or inconsistencies can be identified and corrected before the packaged flour leaves the production line.

5. Dispatch: The packed flour is then dispatched from the production facility and sent to distributors or retailers.

Overall, the packaging process of a flour packing machine is designed to be fast, accurate, and efficient. This helps ensure that the packaged flour meets the required quality standards and is delivered timely to customers.

How to use “flour packing machine”

A flour packing machine is a great investment for businesses involved in the production and distribution of flour products. It is designed to pack flour into various predefined quantities, ranging from a few grams to several kilograms, depending on the packaging requirements of a particular business. Here are some basic steps to follow when using a flour packing machine:

1. Preparation: Before using the machine, ensure that all the necessary equipment and materials are in place, including the packaging bags, flour, and the machine. Then, sterilize the packaging bags and the machine to maintain hygiene.

2. Setting up the machine: The next step is setting up the machine according to specific packaging requirements which can include the quantity of flour, size of the packaging bag, and the sealing system. Ensure that the machine is connected to a power source, and that the various settings and adjustments are made correctly.

3. Starting the machine: Once the machine has been set, it is ready to start packing. Fill the flour into the machine feed system, and the machine will automatically weigh and pack the flour into the sealed packaging bags.

4. Finishing up: After packing, the bags will be sealed automatically and ready for distribution. Clean and sterilize the machine to maintain hygiene, shut off the power source, store the machine, and the packed flour products.

In conclusion, investing in a flour packing machine is an excellent way for businesses to improve their productivity and efficiency in the packaging process. The steps outlined above must be followed correctly to get the best quality packaging, save time and resources while enhancing the production rate, and maximize profitability.

List Properties of “flour packing machine”

A flour packing machine is an essential piece of equipment used in the packaging of flour. The machine is designed to fill flour into bags, jars, or other containers. The machine offers an automated way to pack flour, which increases efficiency and productivity while reducing labor costs. Below are some properties of a flour packing machine:

1. Capacity: Flour packing machines come in a variety of sizes and capacities to suit different production needs. The capacity refers to the amount of flour that can be packed per hour (or per day), ranging from small-scale to large-scale productions.

2. Accuracy: Flour packing machines are designed to ensure that the amount of flour packed into each bag or container is accurate and consistent. This property is crucial to ensure that customers receive the correct quantity of flour, and help maintain product quality.

3. Durability: Flour packing machines are built to last and withstand harsh production environments. The components and materials used in the machine’s construction are carefully selected to ensure longevity and efficiency.

4. Control Panel: Flour packing machines are equipped with control panels, which allow operators to adjust settings such as speed, weight, and bag size. The control panels make it easy for operators to operate the machine efficiently and minimize errors.

5. Easy Maintenance: Flour packing machines are designed for easy maintenance, with features such as accessible components, user-friendly designs, and easy-to-follow maintenance instructions.

6. Safety Features: Flour packing machines come with safety features such as emergency stop buttons, safety switches, and alarms. These features help prevent accidents and protect operators and other staff.

7. Flexibility: Flour packing machines are designed to work with different types of bags and containers, including paper bags, plastic bags, and jars. The flexibility of the machine allows operators to switch between different packaging options to suit their customers and production needs.

In conclusion, a flour packing machine is an indispensable tool in the production and packaging of flour products. The properties listed above are essential for ensuring that the machine operates efficiently, accurately, and safely, while minimizing errors and maintenance costs.

List “flour packing machine” FAQ

1. What is a flour packing machine?

A flour packing machine is a specialized piece of equipment that is designed to accurately measure and dispense flour into bags or containers for shipping or sale.

2. How does a flour packing machine work?

Flour packing machines use a combination of sensors, conveyors, and weighing systems to measure out a precise amount of flour, which is then dispensed into bags or containers.

3. What are the benefits of using a flour packing machine?

Using a flour packing machine helps to reduce waste, increase accuracy, and improve overall efficiency when packaging large quantities of flour.

4. What types of flour can be packed using a flour packing machine?

Flour packing machines can be used for a variety of flours such as wheat flour, all-purpose flour, bread flour, cake flour, and pastry flour.

5. What are some features to look for when purchasing a flour packing machine?

When considering a flour packing machine, look for features such as multiple feeding options, high accuracy, and a user-friendly interface.

6. How much space do I need to install a flour packing machine?

The amount of space required will depend on the specific model and capacity of the flour packing machine, but generally, these machines are compact and can easily fit into most commercial spaces.

7. Can a flour packing machine be customized to fit my specific needs?

Yes, many manufacturers offer customizations to their flour packing machines to fit specific needs such as packaging size, feeding options, and output capacity.

8. Do flour packing machines require a lot of maintenance?

While there are some maintenance requirements such as cleaning and replacing parts as needed, most flour packing machines are designed with durability and ease of maintenance in mind.

9. What is the lifespan of a flour packing machine?

With proper maintenance and regular upkeep, a flour packing machine can last for several years, making it a worthwhile investment for flour manufacturers and distributors.

10. How much does a flour packing machine cost?

The cost of a flour packing machine will vary depending on its size, specific features, and manufacturer. However, pricing generally ranges from a few thousand to tens of thousands of dollars.