List Technical Parameters of "fruit vegetable packaging machines"

Fruit and vegetable packaging machines are specialized equipment designed for efficient and protective packaging of produce. Here are the key technical parameters to consider:

1. Packaging Speed:

- Measured in packs per minute (PPM).

- Determines efficiency and throughput of the machine.

2. Packaging Type:

– Types: Clamshells, trays, pouches, flow packs, vacuum packs, net bags.

- Adaptability to different packaging types is crucial.

3. Product Handling:

- Gentle handling mechanisms to prevent damage.

- Features like soft rollers, gentle conveyors, and variable speed control.

4. Weight Range:

- Customizable settings to handle various weights.

- Typically ranges from a few grams to several kilograms.

5. Dimensions:

- Compatibility with different sizes of fruits and vegetables.

- Adjustable elements to accommodate varying dimensions.

6. Material Compatibility:

- Packaging materials like plastics, paper, biodegradable films.

- Machine’s ability to handle various packaging materials.

7. Automation Level:

- Manual, semi-automatic, or fully automatic operations.

- Includes features like automatic feeding, sealing, and labeling.

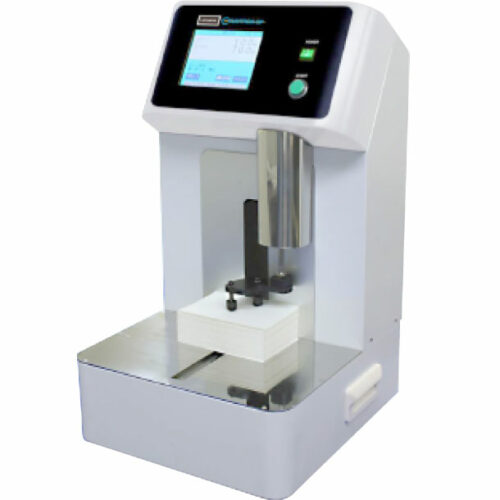

8. Control System:

- PLC (Programmable Logic Controller) with HMI (Human-Machine Interface).

- Allows precise control and easy operation.

9. Sealing Mechanism:

- Heat sealing, ultrasonic sealing, or adhesive sealing.

- Maintains freshness and integrity of the produce.

10. Power Requirements:

- Voltage and power consumption specifications.

- Determines compatibility with available power sources.

11. Construction Material:

- Food-grade stainless steel is preferred.

- Ensures hygiene and durability.

12. Cleaning and Maintenance:

- Ease of disassembly for cleaning.

- Maintenance features to minimize downtime.

13. Safety Features:

- Emergency stop buttons, safety guards, and interlocks.

- Ensures operator safety.

14. Environment Suitability:

- Operating temperature and humidity ranges.

- Designed for use in diverse environmental conditions.

15. Integration Capability:

- Compatibility with existing production lines.

- Ability to integrate with upstream and downstream equipment.

Understanding these parameters helps in selecting the right packaging machine for specific fruit and vegetable applications, ensuring efficiency, safety, and product quality.

List Product features of "fruit vegetable packaging machines"

Fruit vegetable packaging machines are essential for efficient and hygienic handling of produce. Below are some key features:

1. Automated Packaging: Automates the packaging process, ensuring consistency and reducing the need for manual labor.

2. Versatility: Capable of handling various types and sizes of fruits and vegetables, from delicate berries to bulkier items like potatoes.

3. Adjustable Settings: Includes customizable settings for different packaging materials (plastic, film, cartons) and sizes.

4. High Speed and Efficiency: Designed for high-speed operation, increasing throughput and reducing packaging time.

5. Gentle Handling: Utilizes soft conveyors, cushioned hoppers, and non-abrasive surfaces to minimize bruising and damage to delicate produce.

6. Hygiene and Safety: Built with food-grade materials, easy-to-clean designs, and compliance with safety standards to prevent contamination.

7. Weight and Count Accuracy: Incorporates precise weighing and counting mechanisms to ensure correct packaging quantity, reducing product waste.

8. User-friendly Interface: Equipped with intuitive touchscreens and control panels for easy operation and quick adjustments.

9. Integration Capabilities: Can be integrated with other systems like labeling, washing, and sorting machines for a streamlined production line.

10. Sealing Options: Offers various sealing techniques (vacuum, heat, twist ties) to extend shelf life and maintain freshness.

11. Energy Efficiency: Designed to consume less power, contributing to reduced operational costs and environmental impact.

12. Compact Design: Space-saving designs that fit well in a variety of production environments.

13. Remote Monitoring and Diagnostics: Features remote access for monitoring performance and diagnosing issues, facilitating maintenance and minimizing downtime.

14. Scalability: Configurable to accommodate different production scales, from small-scale operations to large industrial setups.

These features collectively enhance the efficiency, effectiveness, and hygiene of the packaging process for fruits and vegetables, addressing both operational needs and consumer expectations.

List Application of "fruit vegetable packaging machines"

Fruit and vegetable packaging machines are vital in various sectors due to their efficiency in handling, packaging, and preserving fresh produce. Below are some key applications of these machines:

1. Agricultural Sector:

– Farm Level Packaging: These machines help in the initial packaging stages right after harvesting, ensuring minimal handling and contamination.

– Post-Harvest Processing: They are used for sorting, washing, and packing, thus maintaining product quality and extending shelf life.

2. Food Processing Industry:

– Pre-Cut and Ready-to-Eat Produce: Machines package pre-cut fruits and vegetables in consumer-friendly formats like salads, fresh-cut fruits, and mixed vegetables.

– Frozen Foods: These devices are essential for packaging vegetables and fruits that are to be frozen, ensuring airtight sealing to maintain freshness.

3. Retail and Supermarkets:

– On-Shelf Packaging: Produce is packed for direct display and sale in supermarkets, offering consumers convenience and ensuring product hygiene.

– Bulk Handling: Machines package produce in bulk for easier transportation and storage within retail operations.

4. Export and Wholesale Market:

– Long-Distance Shipping: Packaging machines ensure fruits and vegetables are packed securely to withstand long transportation times, maintaining quality over extended periods.

– Compliance with Standards: They help meet international packaging standards, necessary for export to various countries.

5. E-Commerce and Home Delivery Services:

– Custom Packaging: Facilitate customized packaging for home delivery services, ensuring products remain fresh and undamaged during transit.

– Subscription Boxes: Efficiently pack produce into subscription boxes, providing a streamlined supply chain solution for subscription-based services.

6. Cold Chains and Logistics:

– Temperature-Sensitive Packaging: Ensure that fruits and vegetables are packed in materials that help maintain the required temperature, reducing spoilage during transport.

Overall, fruit and vegetable packaging machines are essential for enhancing efficiency, preserving quality, and extending the shelf life of produce across various applications and industries.

List Various Types of "fruit vegetable packaging machines"

Certainly! Here are several types of fruit and vegetable packaging machines:

1. Vertical Form-Fill-Seal (VFFS) Machines: These machines create bags from a flat roll of film while filling them with produce. They are highly versatile, handling different produce types and bag sizes.

2. Horizontal Flow Wrappers: Ideal for packaging individual fruits or vegetables, these machines wrap produce in plastic film, creating a sealed package in a horizontal flow process.

3. Tray Sealing Machines: These place fruits and vegetables in trays and then seal them with a film. They are suitable for items needing better protection and presentation.

4. Thermoforming Machines: These machines create customized plastic containers directly from a plastic sheet, fill them with produce, and seal the containers, ensuring durability and freshness.

5. Clamshell Fillers: Specifically for clamshell containers, these machines automate the filling and lidding process, often used for berries and delicate fruits.

6. Net Packing Machines: Ideal for citrus fruits, onions, and other bulk packages, these machines pack produce in netting, which is then closed with metal clips or thermal sealing.

7. Flow Pack Machines: For longer shelf life and enhanced presentation, these machines pack produce in a flow-packed bag, usually with a modified atmosphere to maintain freshness.

8. Vacuum Packing Machines: These remove air from the packaging and seal the produce in a vacuum-sealed bag, extending shelf life significantly.

9. Weighing and Counting Machines: Often integrated with other packaging equipment, these machines ensure the correct amount or number of fruits/vegetables per package, enhancing accuracy and efficiency.

10. Punnet Filling Machines: Specifically designed to fill punnets or smaller containers with fruits like strawberries and cherry tomatoes, often used in conjunction with top-sealing or lidding systems.

Each type offers unique advantages tailored to specific packaging needs, enhancing efficiency, freshness, and presentation of fruits and vegetables.

Custom Manufacturing Options for fruit vegetable packaging machines

Custom manufacturing options for fruit and vegetable packaging machines enable producers to tailor equipment to specific needs, enhancing efficiency, quality, and sustainability. Here are key customization options:

1. Material Compatibility: Machines can be customized to handle a variety of packaging materials like plastic, paper, or biodegradable options, ensuring the packaging is compatible with the product and environmentally friendly.

2. Size and Capacity: Customize the size and capacity to fit different scales of production – from small family farms to large industrial operations. Adjustable machine dimensions can cater to various fruit and vegetable sizes.

3. Automation Level: Choose the degree of automation according to labor availability and budget. Options range from semi-automatic machines, requiring some manual operation, to fully automated systems that streamline the entire packaging process.

4. Precision and Accuracy: Customize machines with advanced sensors and control systems to ensure precise weighing, sorting, and packaging, reducing waste and improving consistency.

5. Integration with Existing Systems: Machines can be designed to integrate seamlessly with existing processing lines, incorporating standardized connectors and interfaces to facilitate smooth workflow.

6. Hygiene and Safety Features: Enhanced cleaning mechanisms, stainless steel construction, and sanitary design options ensure compliance with food safety standards, reducing contamination risks.

7. Adaptability for Different Packaging Types: Options to switch between various packaging formats such as punnets, bags, or crates without significant downtime.

8. Energy Efficiency: Incorporate energy-efficient components and design principles to reduce operational costs and environmental impact.

9. User Interface: Customizable interface options including touch-screens, multilingual support, and remote monitoring capabilities enhance usability and control.

10. Branding and Labeling: Machines can include automated labeling systems to apply custom labels, barcodes, and branding.

Customization ensures that packaging machines meet the unique requirements of the fruit and vegetable industry, driving productivity, reducing waste, and supporting sustainability goals.

List Quality Control and The Manufacturing Process of "fruit vegetable packaging machines"

Quality Control in Fruit Vegetable Packaging Machines

1. Incoming Material Inspection: Components and raw materials are inspected for conformity with specified standards.

2. In-Process Inspection: Continuous monitoring and checks are conducted during manufacturing to ensure consistency.

3. Final Product Testing: Completed machines undergo rigorous testing to verify functionality, including load tests, speed tests, and safety checks.

4. Compliance Verification: Ensuring all products meet industry standards and regulations, such as ISO certifications.

5. Documentation: Detailed records are maintained for traceability and future reference.

6. Customer Feedback Loop: Feedback is collected and analyzed to identify areas for improvement.

Manufacturing Process of Fruit Vegetable Packaging Machines

1. Design and Prototyping:

– Conceptual Design: Initial design phase, including sketches and CAD models.

– Prototyping: Creation of a working prototype to test design feasibility.

2. Material Selection:

- Choosing the appropriate materials like stainless steel for durability and compliance with food safety standards.

3. Component Fabrication:

– Machining: CNC machines and other tools are used for precision cutting and shaping of components.

– Welding: Various parts are welded together to form the primary structure.

– Surface Treatment: Components undergo treatments like polishing, coating, or painting.

4. Assembly:

- Assembling mechanical parts, electronic systems, and control panels.

- Integration of sensors, conveyors, sealing units, and other key components.

5. Quality Assurance Testing:

- Testing the assembled machine for operational efficiency and safety.

- Adjustments are made based on test results to meet design specifications.

6. Software and Control Integration:

- Installation and configuration of control software and user interfaces.

7. Final Inspection and Packaging:

- Comprehensive final inspection before packaging.

- Proper packaging to ensure safe transportation and delivery to the customer.

8. Installation and Commissioning:

- On-site installation and testing to ensure the machine performs as expected in the actual working environment.

By adhering to strict quality control procedures and a structured manufacturing process, high standards are maintained to deliver reliable and efficient fruit vegetable packaging machines.

How to use "fruit vegetable packaging machines"

Using fruit vegetable packaging machines efficiently involves several steps to ensure that the produce is well-protected, maintains its quality, and is ready for distribution. Here’s a concise guide:

1. Preparation:

– Sort the Produce: Inspect fruits and vegetables for quality. Remove any damaged or spoilt items.

– Clean and Dry: Wash the produce if necessary, and ensure they are dry before packaging to prevent mold and spoilage.

2. Machine Setup:

– Read the Manual: Familiarize yourself with the machine’s instructions.

– Adjust Settings: Set the machine parameters according to the type and size of the produce (e.g., temperature, sealing time, and conveyor speed).

– Load Packaging Material: Place the appropriate packaging material, such as plastic films or bags, into the machine’s designated area.

3. Packaging Process:

– Feed Produce: Load the clean and dry produce onto the machine’s conveyor belt or hopper.

– Monitor Operation: Pay attention to the machine as it operates, ensuring that the produce is being packaged correctly.

– Check Seals: Ensure that all packages are sealed properly to prevent air and contaminants from entering.

4. Quality Control:

– Inspect Packages: Check a sample of the packaged products for quality – look for proper sealing, labeling, and any sign of damage.

– Adjust as Needed: If there are any issues, stop the machine, make the necessary adjustments, and resume packaging.

5. Post-Operation:

– Labeling: Attach product labels, including nutritional information, bar codes, and expiration dates.

– Storage: Place the packages in appropriate storage conditions (refrigerated, if necessary, to extend shelf life).

– Maintenance: Clean the machine following the manufacturer’s guidelines to maintain hygiene and efficiency for future use.

Using fruit vegetable packaging machines enhances productivity and ensures produce quality, making them crucial in modern agricultural operations.

List Properties and Terms of "fruit vegetable packaging machines"

Fruit vegetable packaging machines are sophisticated devices used to package a variety of fruits and vegetables efficiently and effectively. Here are some key properties and terms associated with these machines:

Properties:

1. Automation Level:

– Fully Automatic: Requires minimal human intervention, ideal for high-volume processing.

– Semi-Automatic: Requires some manual operations, suitable for medium to low volume.

2. Speed:

– Output Rate: Measured in pouches or packs per minute (ppm).

3. Accuracy:

– Weighing Precision: Accurate weighing mechanisms to ensure consistent package weight.

– Product Discrimination: Ability to separate and discard defective items.

4. Versatility:

– Adjustable Settings: Adaptable to different sizes and types of fruits and vegetables.

– Multi-format Capability: Can handle various packaging forms (bags, trays, crates).

5. Material Handling:

– Conveyor Systems: Efficient transport of products through the machine.

– Gentle Handling: Minimize bruising or damage to delicate produce.

6. Hygiene and Safety:

– Stainless Steel Construction: Resistant to corrosion and easy to clean.

– Sanitation Features: Designed to meet food safety standards.

Terms:

1. Vertical Form-Fill-Seal (VFFS): A common packaging technique where the product is vertically loaded into pouches formed from a roll of film.

2. Modified Atmosphere Packaging (MAP): A technology that alters the atmosphere inside the package to extend shelf life.

3. Fillers:

– Volumetric Filler: Measures product volume for filling.

– Gravimetric Filler: Measures product weight.

4. Sealers:

– Heat Sealing: Using heat to bond packaging seams.

– Impulse Sealing: Heat is applied only when sealing, reducing energy use.

5. Labeling Systems: Machines equipped with mechanisms to apply labels for branding, barcoding, and information.

6. PLC Control: Programmable Logic Controller systems for precise machine operation and easy adjustments.

These properties and terms help in understanding the functionalities and capabilities of fruit vegetable packaging machines, guiding buyers and operators in selecting the right equipment for their needs.

List The Evolution history of "fruit vegetable packaging machines"

The evolution of fruit and vegetable packaging machines reflects technological advancements and market demands over time. Here’s a brief history:

1. Manual Packing (Pre-20th Century): Initially, fruits and vegetables were packed manually using simple materials like wood, straw, and cloth. Labor-intensive processes dominated, with limited attention to hygiene and preservation.

2. Early Mechanization (Early 20th Century): With industrialization, basic mechanized systems like conveyors, weighing scales, and hand-operated sealers were introduced. Wooden crates and burlap sacks were common, improving efficiency and handling.

3. Introduction of Plastics (Mid-20th Century): Plastic materials revolutionized packaging. Machines capable of producing plastic film, laminated bags, and shrink wraps emerged. This era saw the development of semi-automatic sealing and wrapping machines.

4. Automatic Packaging Machines (1960s-1980s): Fully automatic packaging machines began to appear, incorporating technologies like belt conveyors, automatic weighers, and thermal sealing. Modified Atmosphere Packaging (MAP) started, extending the shelf life of produce.

5. Computer Control Systems (1990s): Integration of computer controls and programmable logic controllers (PLCs) increased precision, efficiency, and customization in packaging processes. Machines could now handle various packaging formats faster and more accurately.

6. Sustainability and Advanced Technologies (2000s-Present): Growing environmental awareness led to the development of eco-friendly packaging materials and technologies. Smart packaging options, incorporating Internet of Things (IoT) and sensors, emerged to monitor and preserve freshness. Machines became more energy-efficient and capable of higher throughput with minimal human intervention.

Today, high-speed, fully automated packaging lines dominate, integrating vision systems, robotics, and artificial intelligence to ensure quality and efficiency. The continuous evolution is driven by the need for sustainability, convenience, and extended product shelf life.

How to Select a Reliable fruit vegetable packaging machines

Selecting a reliable fruit and vegetable packaging machine involves several key steps:

1. Determine Your Needs: Assess the specific types of fruits and vegetables you plan to package. Consider factors such as packaging material, size, shape, and the desired speed of operation.

2. Research Reputable Manufacturers: Look for established manufacturers known for quality and reliability. Brands with positive reviews and testimonials can often be more trusted.

3. Check Machine Features: Ensure the machine offers essential features like precision in weighing, ease of operation, and minimal wastage. Automation capabilities and flexibility in packaging styles can also be beneficial.

4. Consider Build Quality: A robust, stainless-steel construction ensures durability and resistance to corrosion, which is crucial for food safety and long-term use.

5. Evaluate Warranty and Support: Choose a manufacturer that offers a good warranty and reliable customer support. This ensures help is available if any issues arise.

6. Request Demonstrations and Trials: Whenever possible, see the machine in action. Some manufacturers may offer demonstrations or trial periods to validate the machine’s performance in real-world conditions.

7. Compare Cost and Value: While budget is a consideration, prioritize value over the lowest price. A higher upfront cost might be justified by lower maintenance costs and better efficiency.

8. Check Compliance and Certifications: Ensure the machine complies with relevant food safety and industry standards, like ISO or FDA certifications.

In summary, carefully assess your needs, prioritize reputable brands, and ensure the chosen machine meets all practical and regulatory requirements. By doing this, you are more likely to select a reliable and efficient fruit and vegetable packaging machine.

List "fruit vegetable packaging machines" FAQ

Certainly! Here is a concise list of frequently asked questions (FAQ) regarding fruit and vegetable packaging machines:

-

What types of packaging machines are available for fruits and vegetables?

- Various machines are available, including flow wrappers, weigh-fillers, tray sealers, vacuum packers, and vertical form fill seal machines.

-

How do packaging machines help in extending the shelf life of fruits and vegetables?

- They utilize methods such as vacuum sealing, modified atmosphere packaging (MAP), and moisture control to reduce spoilage and contamination, thereby extending shelf life.

-

Can these machines handle both fruits and vegetables simultaneously?

- Yes, many machines are designed to handle a variety of produce types with minimal adjustments, ensuring ease of operation and versatility.

-

What materials are commonly used in fruit and vegetable packaging?

- Common materials include polyethylene, polypropylene, and biodegradable films. Trays, pouches, and bags are also widely used.

-

Are the packaging machines easy to operate?

- Most modern machines come with user-friendly interfaces, automated controls, and customizable settings to simplify the operation.

-

What is the average speed of a fruit and vegetable packaging machine?

- Speeds vary by machine type and model, ranging from 30 to over 100 packs per minute.

-

Do these machines require a lot of maintenance?

- Regular maintenance is necessary to ensure longevity and efficiency, but many machines are designed for easy cleaning and quick component replacement.

-

How can I ensure that the packaging is environmentally friendly?

- Choose machines compatible with eco-friendly and recyclable packaging materials. Additionally, some manufacturers offer green packaging solutions.

-

What is the initial cost of purchasing a packaging machine?

- Costs vary depending on functionality, capacity, and brand, but they generally range from several thousand to hundreds of thousands of dollars.

-

Can packaging machines be customized?

- Yes, many suppliers offer customization options to suit specific product sizes, shapes, and packaging requirements.

-

Do I need special training to operate these machines?

- While some basic training is typically required, most machines come with comprehensive user manuals and tutorial videos to facilitate ease of use.

-

Where can I buy fruit and vegetable packaging machines?

- These machines are available through industrial suppliers, online marketplaces, and directly from manufacturers.

This FAQ provides a brief overview to help you understand the key aspects and considerations when looking into fruit and vegetable packaging machines.

Top 10 FAQ with answer about fruit vegetable packaging machines for Buyer Sourcing from China

Sure! Here are the top 10 frequently asked questions (FAQ) with concise answers about fruit and vegetable packaging machines for buyers sourcing from China:

-

What types of packaging machines are available for fruits and vegetables?

- Options include vacuum packing machines, flow wrap machines, tray sealers, pouch packaging machines, and skin pack machines.

-

What materials are used for packaging?

- Common materials include polyethylene (PE), polypropylene (PP), polyester (PET), and biodegradable films.

-

How do I know which machine is best for my product?

- Consider factors like product type, size, required shelf life, and desired packaging format. Consult with suppliers for recommendations based on your needs.

-

What is the typical lead time for delivery?

- Lead times vary but typically range from 4 to 12 weeks, depending on machine complexity and customization requirements.

-

Are there certifications to look for in Chinese manufacturers?

- Look for ISO 9001 quality management certification, CE marking for safety, and local certifications like CCC (China Compulsory Certificate).

-

Can the machines be customized?

- Yes, most manufacturers offer customizations to meet specific requirements, including machine dimensions, packaging types, and automation levels.

-

What after-sales support do manufacturers provide?

- Common support services include installation assistance, operator training, spare parts supply, and remote troubleshooting.

-

What is the usual lifespan of these machines?

- With proper maintenance, packaging machines typically last between 10-15 years.

-

How does one handle maintenance and repair?

- Manufacturers often provide maintenance manuals, training, and remote technical support. Local third-party service providers can also assist.

-

What are the cost factors involved?

- Costs depend on machine type, level of automation, customization, shipping, and installation. Prices can range from a few thousand to several tens of thousands of dollars.

These answers should cover the primary concerns of buyers looking to source fruit and vegetable packaging machines from China.