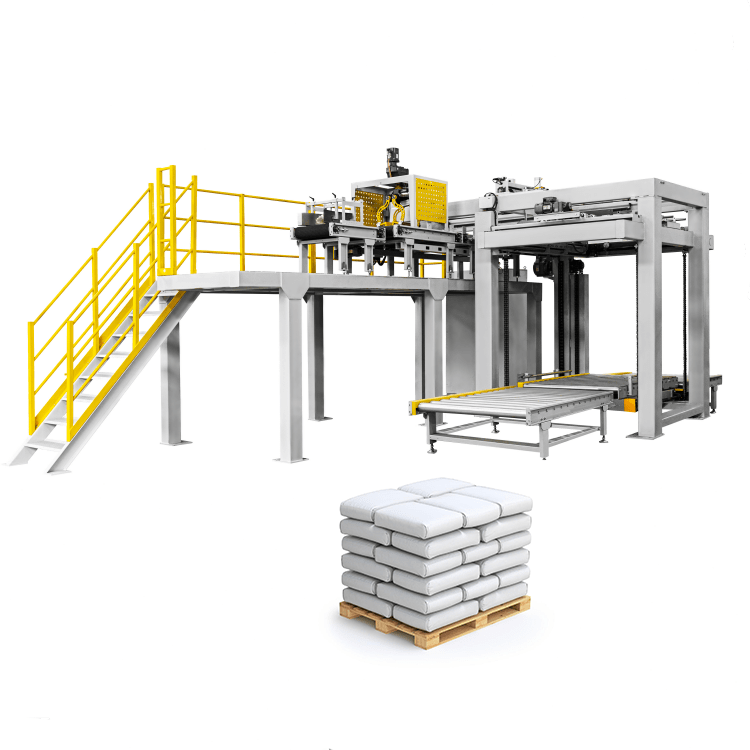

High Level Palletizer Overview

Key Features:

- The High-Level Palletizer Production Line offers a modular design, allowing for customization based on customer requirements.

- Incorporates a Full-automatic Packaging Machine in the packaging process.

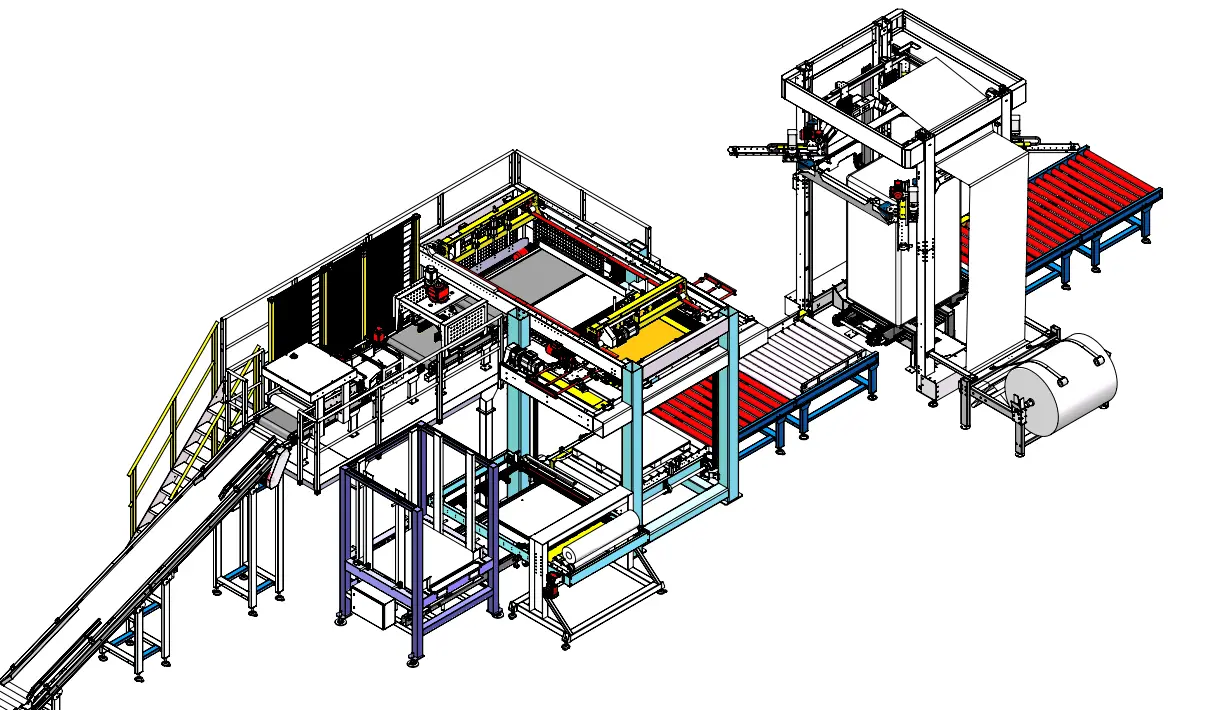

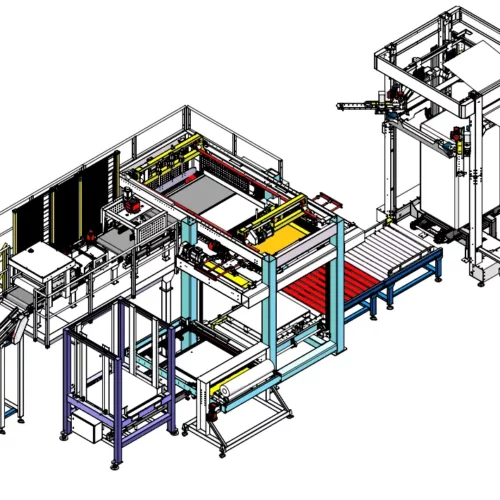

- Components include High-speed Sewing System, Pushing and Convey Mechanism, Double-level Flatting and Convey Mechanism, Transposition Marshalling Mechanism, High Level Palletizer, Automatic Film Packaging Machine, Automatic Pallet Storehouse, and Pallet Convey System, with a production capacity of up to 1200 bags/h.

- Optional Metal Detection System and Weight Detection System can be added to ensure product quality by removing any subpar items.

- Features an Automatic Industrial Inkjet Printer for product identification and tracking, aiding in product control and management.

- Utilizes Film Packaging Machine for enhanced pallet stability, increased output speed of 60 stacks/h, and reduced production costs compared to traditional wrapping methods.

Machine Specifications:

- Model Series: FP-1200/1800/2200

- Palletizing Form: High-level palletizing

- Bag Types: Plastic bags/ woven bags/paper bags

- Packaging Weight: 20-50 kg/bag

- Grouping Method: 2+3

- Palletizing Layer: 8-12

- Palletizing Capacity: 400~1000 bags/h

- Fully Loaded Pallet: ≤1750 kg

- Stack Height: ≤1700mm (including pallet height)

- Power: 15 kW

- Air Consumption: 300 NL/min

- Equipment Size (LWH): 8970 4900 3460

Working Process:

- Flatten Bag: Bags are flattened upon entry using a double belt conveyor.

- Rotate Bag: Material bags are selectively rotated 90 or 180 degrees for grouping purposes.

- Cache Bag: Maintain stable bag distances to avoid collisions and ensure stacking effectiveness.

- Grouping Bag: Bags are grouped using a belt conveyor and stainless steel buffer plate in a 3+2 or 2+3 configuration.

- Push and Press Bag: Grouped bags are pushed onto the pallet and compacted for shaping.

- Empty Pallet Input: Empty pallets are brought from the library and placed under the material bags.

- Full Pallet Output: Stacked bags are lowered onto the pallet and output to the next station after completion.

The High-Level Palletizer Production Line combines efficiency, flexibility, and advanced features to streamline palletizing processes for various bag types and weights.